-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

December 28, 2018

6 Simulation Technologies Aerospace Engineers Don’t Want to Miss in 2019

There are a lot of things attendees can do at aerospace engineering conferences, including:

- Seeing technology advancements.

- Talking to industry experts.

- Participating in committees.

Conferences are also a great place to meet aerospace customers, partners and young professionals.

6 Simulation Technologies Aerospace Engineers Don’t

Want to Miss in 2019

However, not everyone can attend events like the American Institute of Aeronautics and Astronautics’ (AIAA) SciTech Forum.

Therefore, I thought it would be nice to level the playing field by sharing highlights engineers should expect to see in this year’s conference circuit. After all, no engineer should fall behind on the latest tech news.

So, here are six Ansys technologies I think every aerospace engineer should research in 2019.

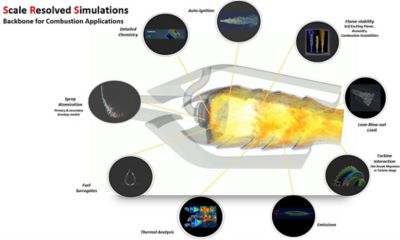

1. Optimize Engine Designs with Scalable Combustion and Turbulence Models

Shortened design cycles and sensor placement limitations prevent aerospace engineers from relying on physical testing.

As a result, aerospace engineers use computational fluid dynamics (CFD) and chemistry solvers to develop the next generation of aircraft engines.

Ansys’ combustion portfolio helps aerospace engineers design engines.

Ansys’ combustion portfolio is well suited to these multiphysics simulations. The software’s high-performance computing (HPC) scalability enables engineers to use turbulence models — like large eddy simulations (LES) — on meshs with more than a million elements.

To learn more, engineers attending the AIAA’s SciTech Forum can meet at a presentation on this combustion technology. If you can’t attend, read the application brief: Using Simulation to Optimize Reacting Flows and Combustion.

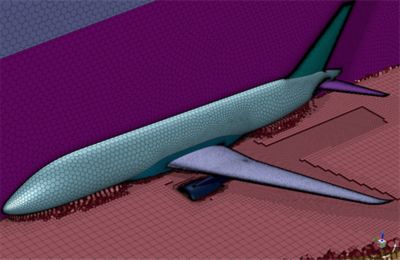

2. Mosaic Meshing Technology Speeds up CFD Pre-processing

It’s tedius to merge CFD meshes. They have to be tight near the boundary layer and coarse in the bulk. The nodes, element types and element sizes just won’t align.

To address this, Ansys has released the new Mosaic meshing methodology. It can automatically mesh large scale models in high-lift configurations.

This Mosaic mesh of an aircraft includes small elements near the

boundary layer and coarse elements in the bulk with polyhedral elements in between.

This Mosaic meshing technology automatically combines a variety of boundary layer meshes using high-quality polyhedral elements.

Research shows that Mosaic meshing creates a better grid with fewer elements. This grid is able to deliver results faster and more accurately than traditional high-lift–configuration meshes.

Engineers can also catch me at a presentation on Mosaic meshing at AIAA’s SciTech Forum. Otherwise, read the white paper Ansys Fluent Mosaic Technology Automatically Combines Disparate Meshes with Polyhedral Elements for Fast, Accurate Flow Resolution.

3. Virtual Reality and Optical Simulations for HMI and Sensor Optimization

Sometimes, aerospace engineers just need to visualize their simulations.

Maybe they need to experience how a cockpit’s human machine interface (HMI) feels. Or maybe they have to assess how a proximity sensor sees through a cloud.

In 2018, Ansys announced the acquisition of CEI and the visualization capabilities it brought to our customers — namely EnSight.

Design the next-generation cockpit with Ansys VRXPERIENCE and Speos.

Now, aerospace engineers can integrate these visualizations with virtual reality — thanks to Ansys’ recent OPTIS acquisition. The acquisition brings the VRXPERIENCE and Speos to the Ansys platform.

The VRXPERIENCE is used to create virtual realities. It can also be coupled with the display solution Ansys SCADE. This enables engineers to explore and validate cockpit designs and other aerospace HMI.

Speos simulates light, human vision and physics-based visualization. It predicts illumination and the optical performance of systems. This way, engineers can prototype the optical performance of sensors digitally instead of in the real world.

Aerospace engineers can also couple the VRXPERIENCE and Speos to create a virtual world that tests their sensor designs. This technology would be ideal for the development of autonomous drones.

To learn more about VRXPERIENCE and Speos, I recommend reading about Ansys' Optics & Virtual Reality offerings.

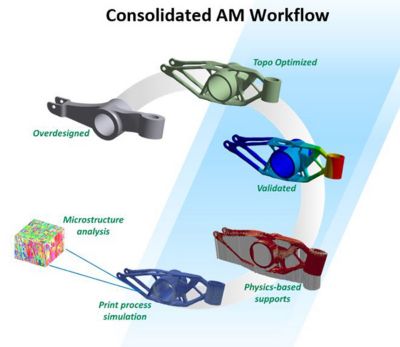

4. Simulate Additive Manufacturing to Print Right the First Time

Additive manufacturing can build novel geometries that are not possible to create using traditional methods.

This provides unique light-weighting solutions for companies in the aerospace sector. They can also produce low volume parts without investing in specialized tools.

However, engineers who implement 3D printers need to learn how to ensure their designs are built properly.

Recently, Ansys launched a new product line focused on 3D printing. This brought the Additive Suite to Ansys Mechanical.

Ansys Additive Suite ensures parts print properly the first time.

The tool offers engineers an end-to-end design solution for metal additive manufacturing.

For instance, it enables engineers to calculate deformations and stresses during the printing process. This data helps them optimize their geometry to print correctly the first time.

To learn more about Additive Suite, I suggest you read Structural Optimization & Additive Manufacturing: A Winning Combination.

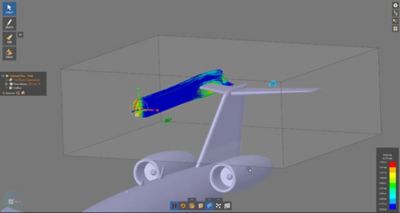

5. Simulate in Real-time with Discovery Live

We have seen the aerospace industry pay more attention to pre-design. This is because the sooner the engineers make informed decisions about their products, the fewer redesigns they will need later in the development cycle.

This is where Ansys Discovery Live shines. It provides simulation insights in real time.

The ease of use and speed of the tool help designers test ideas before engaging an analyst. Discovery Live can model mechanical and CFD simulations in real time.

Discovery Live enables designers to model mechanical and CFD simulations in

real time.

For instance, engineers can set up a parameter study to better understand the trends and trade-offs of their designs in only a few minutes. Using that data, engineers can pass on near optimal designs to the analysts.

The results are so fast that engineers might want to play around with the design a bit and see how the simulation reacts.

To learn how to play around with designs, I recommend reading the blog Modern Product Development Encourages Engineers to Play with Designs.

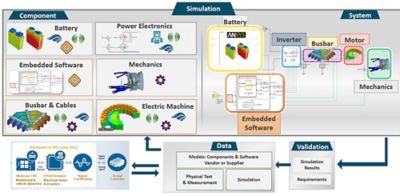

6. Simulate Everything with Multiphysics

Electrification is another major initiative in the aerospace industry. Electric aircraft will help engineers simplify their designs and implement new features like the IoT and digital twin.

Ansys multiphysics solutions will play a key role in the implementation of aerospace electrification.

Multiphysics simulations will help engineers drive the electrification trend in the aerospace industry.

These multidomain tools allows engineers to design and optimize key components, including:

- Batteries

- Fuel cells

- Inverters

- Motors

- Actuators

- Bus bars

- Cables