-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

October 9, 2023

How to Test an Electric Motor

Electric motors power our world. From refrigerator compressors and smartphone actuators to the powertrains of electric vehicles (EVs), everywhere we turn, electric motors make modern life possible. In fact, electric motors are so relied upon that often the only time we notice them is when they don’t work — an issue that’s highly preventable, thanks to electric motor testing.

The Importance of Electric Motor Testing

Electric motor testing is critical to ensuring the machines we depend on are reliable, efficient, and safe. These tests — conducted throughout the stages of an electric motor’s life cycle — provide essential information about the motor’s overall health and provide designers, manufacturers, technicians, and consumers with many benefits.

Electric motor testing improves:

- Reliability: Testing identifies potential issues and allows for proactive maintenance to prevent breakdowns and extend the motor’s lifespan.

- Efficiency: Through testing, technicians can address electrical energy issues to reduce loss and lower operating costs.

- Safety: To protect the people using electric motors, testing exposes potential hazards such as electric shock or fire.

- Performance: Testing reveals opportunities to improve performance by assessing characteristics like speed and energy consumption.

- Research and Development: Testing collects data that informs efforts to create more advanced motor technologies.

- Standards Compliance: Before a motor can be deployed for use, testing validates that it meets all applicable industry standards.

Types of Electric Motor Tests

While the specific tests conducted will vary depending on the complexity of the motor, its application, and the parameters being evaluated, some of the key tests used during electric motor testing include:

- Electrical tests such as polarity checks and voltage level measurements.

- Vibration tests to detect any imbalances or misalignments.

- Thermal tests to monitor the motor’s temperature to avoid overheating.

- Dynamic tests to see how the motor performs in transient states.

- Noise tests to evaluate acoustic characteristics against sound standards.

- Insulation tests to ensure the motor’s insulation materials won’t degrade while operating. Some examples include megger tests, high-potential (hi-pot) tests, and surge testing — which finds weaknesses in turn-to-turn, coil-to-coil, and phase-to-phase insulation that can lead to electrical failure.

Industry Standards for Electric Motor Testing

In every application in which electric motors are used, from industrial compressors to dental drills, testing validates that a motor meets the specifications set by the manufacturer and the quality and safety parameters determined by industry standards (such as energy consumption and sound levels).

To meet industry standards, electric motor tests must address both international and local requirements. At the international level, standards such as interoperability and safety are consistent from country to country, while local standards may include requirements that recognize country-specific priorities, such as the environment and culture. Some of the organizations that create and enforce these standards include:

- National Electrical Manufacturers Association

- International Electrotechnical Commission

- Japanese Industrial Standards Committee

- British Standards Institution

- National Standards for People’s Republic of China

Electric Motor Testing Tools

Are you testing a wind turbine or a transportation system? An industrial fan or an elevator? Depending on the parameters and characteristics you’re evaluating, there are many different types of tools used in electric motor testing. Some of these tools include:

- Power analyzer: measures electrical parameters such as voltage and current to diagnose electrical connections.

- Tachometer: measures the rotational speed of a motor.

- Thermal camera: captures temperature variations to identify hotspots and cooling issues.

- Megohmmeter: measures the insulation resistance of motor windings to detect insulation degradation (also known as meggers).

- Torque transducer: measures torque by converting mechanical rotation into an electrical signal.

Simulation in Electric Motor Testing

While physical testing is critical to gaining insight about motor performance, it has its limitations. Simulation enables technicians to expand testing by seeing inside the machine to reveal exactly what is happening (both now and in the future), as well as showing the health of the deepest inner workings of a motor.

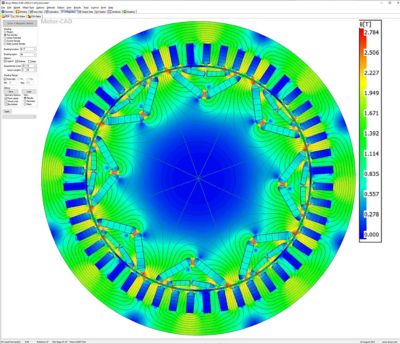

Electric testing: virtual measurement of magnetic flux in a synchronous permanent magnet motor

With simulation, engineers can explore various design options against different operating scenarios and make adjustments before production, during production, and even while the motor is being used. Especially in scenarios in which physical testing is restricted by lack of visibility (due to size or location of the test), simulation can quickly perform the calculations required to make an accurate assessment. Some common electric motor tests that require the use of simulation include:

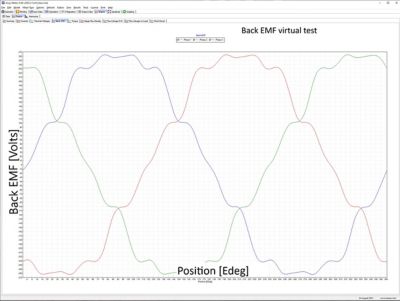

Electrical testing: measuring the back electromagnetic field (EMF) in brushless permanent magnet motors.

Electric testing: virtual measurement of back EMF in a brushless permanent magnet motor

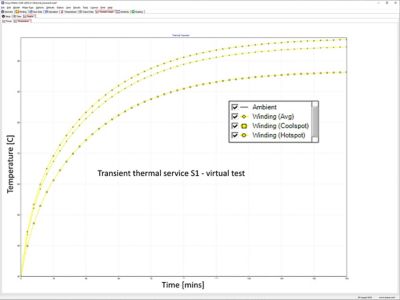

- Thermal testing: estimating overheat during continuous operation S1.

Thermal testing: virtual winding overheat estimation during continuous operation S1 of an electrical motor. The temperature range is between ambient (40 °C) and maximum acceptable temperature (100 °C)

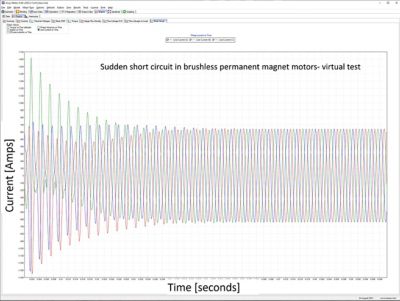

- Dynamic testing: predicting short-circuit fault in brushless permanent magnet motors and measuring locked rotor performance in AC induction motors.

Dynamic testing: virtual measurement of short circuit currents in a brushless permanent magnet motor

The use of simulation in electric motor testing not only improves the speed and efficiency of the testing process itself, but also improves the quality, depth, and reliability or certainty of the data collected. Simulation software like Ansys Maxwell and Ansys Motor-CAD can perform coupled multiphysics calculations, providing technicians with thorough assessments of complex systems — assessments that would be impossible to achieve one test at a time.

By utilizing simulation to run physical tests in a virtual environment, engineering teams can save time and costs. Simulation also reduces the number of design iterations and identifies problems before any hardware is built. This leads to a better, more robust design and ensures no surprises when it comes to the physical testing.

The Answer is Testing

Many of the modern world’s most essential functions rely on the reliability, safety, and efficiency of electric motors. Through testing, we gain the valuable observations, learnings and insights that will lead us to our next technological advancements in power generation, which keep us all moving forward.

Learn more about how Ansys Maxwell helps perform safety analysis and design according to ISO 26262 for electrical and electronic (E/E) systems, view the webinar: Achieving ISO 26262 Functional Safety Compliance with Ansys Maxwell.