-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TAKASAGO is a global leader in fragrance, flavor, and aroma molecules used to create fragrances and flavors. Founded in 1920, the company has expanded from synthetic aroma ingredients to fragrances and flavors while continuing to research cutting-edge technologies. Its philosophy, “Contributing to society in accordance with the spirit of technology," has guided TAKASAGO to create flavors and fragrances that enrich people's lives.

We sat down with TAKASAGO R&D Manager Tiphaine Ribaut and Process Project Manager Kartic Prouchotte to learn more about how TAKASAGO uses innovative technologies to create better fragrances.

What do you specialize in?

Tiphaine: Kartic and I belong to the fragrance division. Our fragrances are used across all categories, from fine fragrances to beauty care and home scents. Thanks to our significant R&D efforts, we are constantly pushing the boundaries of creation by combining science and innovation. We develop unique, captive, and specialty ingredients and have long been pioneers in green chemistry.

What led you to the role of process project manager?

Tiphaine: I decided to create the process project manager role in my team to address specific needs, bridging the gaps between R&D and industrial production, as well as between fundamental laboratory chemistry and industrial-scale chemistry. A key objective of this role is to develop simulations for our various processes, enabling faster, more efficient, and more reliable process development.

Tiphaine Ribaut, R&D manager, TAKASAGO

Kartic Prouchotte, process project manager, TAKASAGO

Kartic: I applied for this position because a process engineer working in the R&D group of a manufacturing company is a golden opportunity. Being in the R&D group is a key opportunity to develop my skills and knowledge with freedom to use various experimental equipment and reactors of different scales. Of course, when it comes to simulation, this is an opportunity for me to test and develop my simulation abilities learned during my master’s for industrial purposes.

What is your favorite part of your job and your proudest accomplishment?

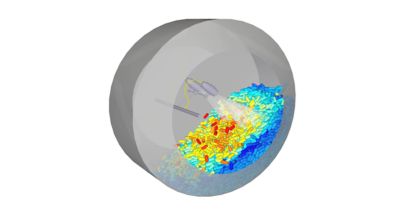

Kartic: The favorite part of my job is designing each object used in simulation, especially complex equipment. Personally, my biggest achievement is designing a high-shear mixer of a reactor, which was the toughest equipment to design until now — then obtaining satisfying results from simulating through Ansys Fluent fluid simulation software.

What are the biggest challenges you face in your role, and how does simulation help you overcome them?

Kartic: As a process project manager focusing on the development of reactors, the biggest challenges are:

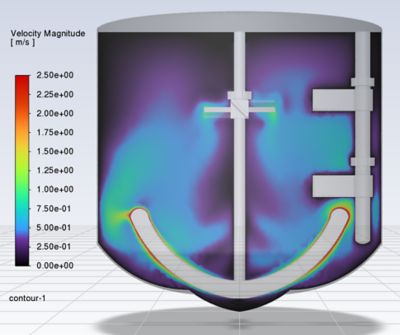

- Studying the flow inside the reactor during the process.

- Predicting the areas that aren’t impacted by the rotation of the reactor’s impeller.

- Finding the optimal and efficient rotational speed of the impeller suited for the process.

With access to Fluent software, these challenges and problems can be resolved by:

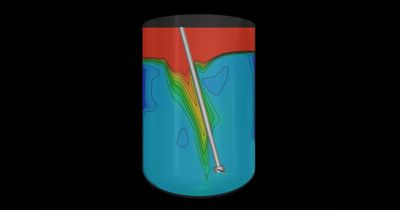

- Getting the velocity contours in the transient state and viewing vectors of the flow.

- Observing the velocity contours in a stable state and tracking particles of the fluid.

- Modifying the speed of the rotational domain and analyzing the velocity contours and path lines at each chosen rotational speed.

What excites you about simulation?

Kartic: The exciting part of simulation is finding the key factors that enable us to upgrade various processes that would take much longer if only practical experiments were performed.

Are you using simulation for any unique or challenging projects?

Kartic: The main reason we use Ansys is to scale up existing processes of TAKASAGO’s R&D department from laboratory to industrial scale. By using Fluent software, we could predict the results of experimental processes without doing them practically.

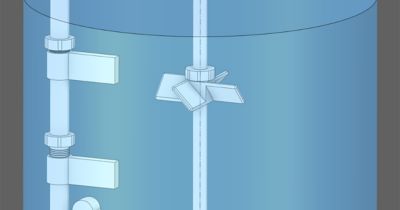

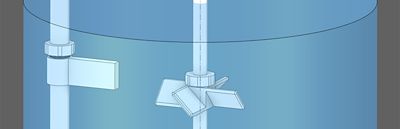

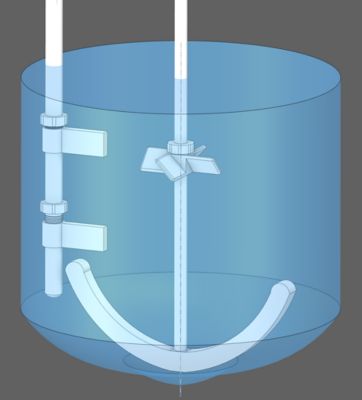

In fact, Ansys Discovery 3D product simulation software gives access to design reactor parts, such as the impeller and vessel, then predicts their utility in advance through Fluent’s simulation before purchasing to judge the efficiency of new impellers or vessels.

From the simulations, we decreased the consumption of raw materials by reducing the number of syntheses and gained a lot of time. For example, a typical industrial synthesis takes three days to obtain results, whereas it can be visualized in half a day using Fluent software.

Left: An Ansys Discovery 3D product simulation software model of a pilot-scale reactor. Right: Velocity contours for a pilot-scale reactor.

Why are you choosing to work with Ansys, part of Synopsys?

Kartic: I was familiar with Ansys software from my studies. The simulation time needed for Fluent software is short, and the access and use of parameters is easy. Moreover, one of the significant factors of our processes is the viscosity of the fluid. It’s a great advantage for Fluent software to have various viscosity models.

What advice would you give R&D teams looking to start using simulation?

Kartic: First, I would advise them to learn any computer-aided design (CAD) software, then understand the basics of meshing processes.

Next, they can dive into the major part, which is the computational fluid dynamics (CFD) software. Study and identify the key parameters of the experimental process. This can be learned step by step using Fluent software.

When you think about the future, how will simulation help advance innovation at TAKASAGO?

Tiphaine: We see a great opportunity in expanding the use of simulation across our projects. We can explore new concepts faster and optimize processes sustainably.

Kartic: Simulation will help to advance innovation at TAKASAGO in many ways:

- Guide us to have the most suitable equipment for each process.

- Enable us to identify the most optimal, efficient parameters to apply in the reactors.

- Easily scale up each process from laboratory to industrial scale.

Learn more about how Fluent software can help with your fluids applications.

Just for you. We have some additional resources you may enjoy.

“We see a great opportunity in expanding the use of simulation across our projects.”

— Tiphaine Ribaut, R&D manager, TAKASAGO

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.