ACCELERATE YOUR MANUFACTURING PROCESS

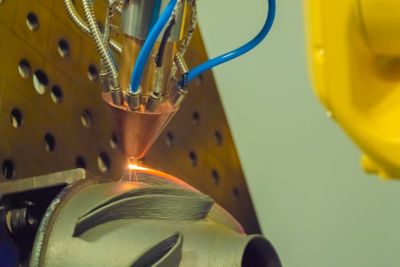

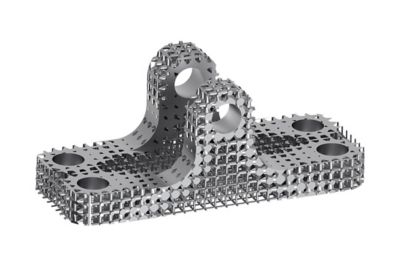

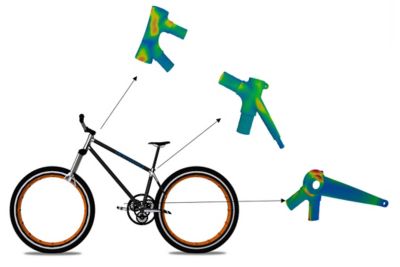

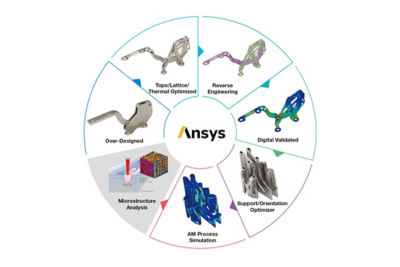

A COMPREHENSIVE SOLUTION CONVERGING DESIGN, SIMULATION, AND ADDITIVE MANUFACTURING

Gain insights through automated workflows to eliminate the risk of distorted or out of tolerance parts, and ensure high quality components.