-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

トピックの詳細

計算材料科学とは

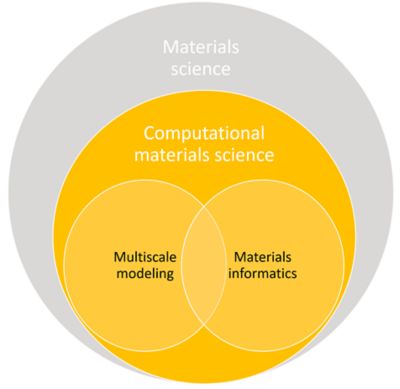

計算材料科学は、基礎研究と製品設計の双方で、より効率的な材料探索、材料設計、故障特性評価、材料モデリングを可能にする学際的分野です。計算材料科学は、エンジニアが材料の挙動や、機械、熱、電磁界などの材料特性を調査できるようにする一連の手法で構成されています。

計算材料科学に含まれるマルチスケールモデリングとマテリアルズインフォマティクスは、部分的に重複する補完的なアプローチであり、物理ベースの手法とデータ駆動型の手法を組み合わせて材料挙動を理解、予測、最適化する。

計算材料科学を通じて、新しい材料設計をより理解できるだけでなく、分野横断的な研究を介して知識を伝達できるようになります。多くの工業分野では、計算材料科学の進歩により、プロトタイプを何度も作製することなく、より効率的な材料システムや高性能な製品を設計できるようになりました。

計算材料科学のトレンド

先端材料、複合材料(セラミック、炭素、ポリマー複合材料)、その他のソリッドステート材料など、化学および材料科学の研究開発の多くの分野では、さまざまな計算手法が採用されています。また、計算材料科学はエネルギー生産や半導体などのさまざまな技術分野にまで及びます。

計算材料科学は、計算能力とシミュレーションソフトウェアの進歩とともに発展し続けています。

この数年間で最も顕著なトレンドの1つであり、現在では機能として追加されているのが、プロセスモデリングへのリンクと、製造プロセスが材料の特性に与える影響です。デジタル製造を導入する企業が増えるにつれて、計算材料科学の手法でも、これらのプロセスを理解して改善するための多数の機能が提供されるようになりました。

ここ数年で開発や導入が増えているもう1つの分野は、マルチスケールモデリングです。これは、計算手法とエンジニアリング手法を組み合わせて、原子レベルからマクロレベルまで、複数の長さスケールにわたって最適化される材料特性と材料挙動を予測するアプローチです。最近では、材料の設計時に、このシミュレーションアプローチが採用されることが多くなっており、透過型電子顕微鏡法(TEM: Transmission Electron Microscopy)や走査型電子顕微鏡法(SEM: Scanning Electron Microscopy)などの実験的な特性評価技術と組み合わせることで、ナノスケール以上の材料設計をさらに発展させることができます。

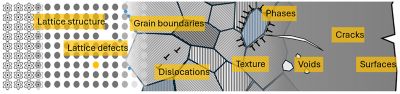

材料は、複数の長さスケールにわたって構造と欠陥が相互に作用することで巨視的な特性が生じる複雑な系であり、その正確な記述には、マルチスケールモデリングアプローチが必要となることが多い。図に、材料で見られるさまざまな構造欠陥の例を示す。

ソフトウェアの観点で現在最大のトレンドとなっているのは、他の多くの分野と同様、人工知能(AI)です。多様なAIアルゴリズムを導入し、関連するシミュレーション(および実験)データを入力すると、材料の特性とプロセスをさらに正確に予測および最適化できるようになります。これは、材料特性を予測して、材料開発の効率を向上させるために、機械学習アルゴリズムを使用する計算材料科学およびマテリアルズインフォマティクスにおいて成熟し始めているツールです。

原子スケールでの計算モデリング

計算材料科学を用いることで、原子レベルやナノスケールレベルを含む、低長さスケールでの材料の構造や特性を理解できるようになります。

ハイスループット計算スクリーニングでは、材料自体をモデリングするだけでなく、まだ製造されていない材料の(組成と結晶構造に基づく)既知の特性を大規模なデータベースから取得して、特定用途に最適な特性を持つ材料/材料構造を特定できます。調査対象となる材料の多くは、重視すべき特性を複数持っています。そのため、このアプローチでは一度に1つの特性に焦点を当て、複数の特性を探索しながら、潜在的に適切な材料の数を徐々に絞り込んでいきます。この方法により、試行錯誤の実験アプローチで最適な材料を見つける必要がなくなるため、時間とエネルギーを節約しながら、材料の開発を加速できます。ただし、こうしたシミュレーションは計算負荷が高く、処理時間が長くなったり、高い処理能力を備えたコンピュータが必要となったりします。

計算モデリング手法の多くは原子レベルでシミュレーションを実行します。また、特定の材料や用途に合わせて、主要な手法の多くのバリエーションが適応されています。あらゆるアプローチの中で最も一般的なのは密度汎関数理論(DFT: Density Functional Theory)、分子動力学(MD: Molecular Dynamics)シミュレーション、そしてモンテカルロシミュレーションです。

- 密度汎関数理論(DFT): DFTは、密度に基づいて材料内で電子がどのように振る舞うかをシミュレーションする量子力学モデルです。これは、材料の基底状態特性(原子の最低エネルギー状態)と機械的特性を予測して、化学特定やエネルギー特性を推定するために最も広く使用されている電子構造論の手法です。

- 分子動力学(MD): MDは、シミュレーション内のすべての原子がどのように振る舞い、他の原子と相互作用するかを予測し、時間の経過とともに原子が物理的にどのように移動するかについての知見をもたらす物理ベースのモデルです。原子の位置と応力を用いて材料特性を予測できます。また、MDシミュレーションに機械学習機能を組み込むことで精度が向上し、シミュレーションの計算コストを削減できます。

- モンテカルロ: モンテカルロシミュレーションは、繰り返しランダムサンプリングを用いて結果の確率を予測する計算アルゴリズムです。粒子の相互作用や複雑なシステムをシミュレーションする確率ベースのツールです。

より大きなスケールでの計算モデリング

計算ツールの多くは、原子スケールだけでなく、材料の多数の層にわたって、はるかに大きなスケールで材料特性を予測するためにも使用されます。こうしたマルチスケールモデリングアプローチでは、材料のマクロ特性(機械的特性や電磁界特性など)を調べ、微細構造を調査し、(特に過酷な用途の)極端な条件下で材料がどのように振る舞うかを調べます。

より大きなスケールでのモデリング手法は、連続体レベルのモデリングの1つとして分類され、より小さな分子スケールで得られた情報を使用して、より大きな材料システムとの接続を確立します。このシーケンシャルなアプローチを導入すると、原子レベルでは、計算負荷は高いが、より正確なモデリングが可能となり、基礎的な情報を得られた後に、計算負荷の低いマイクロスケールモデリングを行えるようになります。

現在、材料システム全体のモデリングを行うためのさまざまな計算ツールが提供されていますが、一般的なツールとして、有限要素法(FEM: Finite Element Method)、フェーズフィールド法、計算状態図(CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry)があります。

- 有限要素法(FEM): FEMは、微分方程式を使用して複雑な材料システムをより小さな要素のメッシュに分割し、個々の要素を個別に解析する数値ベースのシミュレーションです。各要素がどのように振る舞うかを理解することで、特定の条件下で材料全体がどのように振る舞うかを把握できるようになります。FEMは、材料の構造解析を実行したり、質量の移動、流体流れ、材料の電磁界特性を調査したりするために使用されます。FEMの結果の解釈は、有限要素法解析(FEA: Finite Element Analysis)で実行できます。

- フェーズフィールド法シミュレーション: フェーズフィールド法モデルは、材料の界面における問題を解決する数学モデルです。材料の凝固および界面ダイナミクスをモデル化して、破壊力学や脆性などの機械的特性を調査するために使用できます。また、結晶方向や特定の相など、特定のパラメータに基づいて材料の微細構造を調査する混相流モデルを作成したり、複数の熱力学的な相を持つ材料の特性を調査したりできます。

- CALPHAD: 異なる温度や化学組成での材料の相安定性を予測するために相図を生成するモデルです。CALPHADモデルは、材料内の各相の熱力学的特性を用いてシミュレーションを実行し、さまざまな条件下で材料がどのように振る舞うかをより深く理解するために使用されます。

計算材料科学の機会と課題

他のシミュレーションや計算手法と同様に、計算材料科学アプローチにも利点と欠点があります。また、ある材料に対して適切なシミュレーションアプローチが必ずしも別の材料に適切であるとは限らないため、どのツールセットを選択するかによっても利点と欠点は異なります。使用できる計算ツールセットはさまざまですが、共通する利点と欠点はいくつかあります。

計算材料科学の機会

- 試行錯誤に基づくアプローチを、ターゲットを考慮したシミュレーションに置き換えることで、製品サイクルの初期段階で、材料の合成とテストの両方を含む広範な実験開発の必要性を減らすことができます。

- 実験では達成が難しい、非常に具体的な特性、プロセス、基本メカニズム、材料環境、そして適用シナリオを検討するために使用できます。

- 基礎材料科学と他の業界や適用分野とのギャップを埋めるのに役立ちます。

- 多くの業界で、材料をより深く理解できるようになります。

- エンドユーザーは、既成概念にとらわれず、材料を設計パラメータとして考慮できるようになり、より複雑な材料の開発につながります。

計算材料科学の制約

- 材料の構造とその特性関係について得られる情報は、場合によっては一般化されすぎてしまう一方で、実験で使用する大半の特性や材料パラメータは、具体的な値を用いて定量化されることが少なくありません。

- 一部のメカニズムは複雑であるため、材料挙動を適切に理解するためには実験を行う必要があります。故障や損傷などの現象は、計算のみで捉えることは非常に困難です。

- シミュレーションは、利用できる計算能力によって制限される場合があります(シミュレーション時間が長くなる)。

計算材料科学の課題

- 特定のケースに対する計算科学手法を構築することは難しいため、投資利益率(ROI: Return On Investment)は多くの場合不明確です。

- 手法を再利用できる場合にのみ利点がもたらされる、コストと時間のかかるプロセスです。

- 多くの場合、計算モデルの利点を最大限に活用するには、専門分野を横断する幅広い知識が必要となります。

AIは計算材料科学を改善できるか

前述のように、計算材料科学でAIアルゴリズムを導入することはもはや珍しくありませんが、材料工学や機械工学の分野でAIは具体的にどのようにエンジニアをサポートしているのでしょうか。

AIは、原子レベルから顕微鏡レベルでより多くの実用性が見いだされており、シミュレーションソフトウェアの予測機能の向上と、より正確な材料特性の特定に貢献しています。機械学習は、DFTと同等の精度を実現することで、MDシミュレーションにも大きな影響を及ぼします(一般に、DFTの精度の方が高い)。特性評価の自動解析、自動ラボ、プロセス最適化、マルチスケールモデリングなど、他のAIアプリケーションも登場しています。

商用AIテクノロジーの急速な進歩により、利用できるオプションが増えており、現在使用されているAIによって材料科学情報へのアクセシビリティが向上しています。計算材料科学におけるAIの活用は、まだ移行段階にありますが、次のどちらか一方が発生した時点で、より多くのツールにまたがる広範な統合が行われるでしょう。

- 技術的なニーズが生じた場合。

- 材料科学コミュニティにとって、材料設計のより多くの領域で採用した方が費用対効果が高くなる場合。

計算材料科学の導入を検討している企業に対するAnsysのサポート

新材料は、高度な機能や特性を実現するために本質的に複雑になっており、さまざまな材料設計フェーズで利用できるすべてのツールを最大限に活用することが、これまで以上に重要になっています。

Ansys, part of Synopsysは、マクロスケールレベルでお客様をサポートし、材料のマルチスケールシミュレーションに役立つ材料科学者向けのさまざまなシミュレーションツールを提供しています。ただし、材料システムの構造や特性をシミュレーションする上で、万能なアプローチはありません。対象となる材料や用途に応じて、Ansysで採用しているツールからPythonベースのアプローチまで、さまざまなシミュレーションツールを組み合わせて導入することが推奨されます。

以下に、材料設計段階で使用できるAnsysのツールをいくつか挙げます。

- 非線形動的構造シミュレーションソフトウェアであるAnsys LS-DYNA: LS-DYNAを使用すると、マイクロスケールとマクロスケールを組み合わせたマルチスケールシミュレーションを実行できます。

- Ansys Materials Designer: Materials Designerを使用して、材料ネットワークを探索し、微細構造を調査できます。また、均質化調査のためのネイティブなアドオンや使いやすいフロントエンドも提供されます。

- 材料情報、選択、およびデータ管理のためのAnsys Granta製品コレクション: Grantaを使用して、材料データを管理し、設計プロセスでさまざまなモデルをサポートできます。Granta AIプラグインを使用して、データ管理とサポートを改善することもできます。

- シミュレーションプロセスおよびデータ管理ソフトウェアであるAnsys Minerva: Minervaでは、安全なシミュレーションとプロセスデータが提供されることで、材料設計プロセス全体で作成されるすべてのシミュレーションとデータのトレーサビリティが確立されます。

- 構造の有限要素法解析ソフトウェアであるAnsys Mechanical: Mechanicalを使用すると、マイクロスケールとマクロスケールを組み合わせたマルチスケールシミュレーションで結晶塑性とMAPDLを使用できるようになります。異なる相で代表的最小体積(REV: Representative Elementary Volume)をテストする際に、多点拘束(MPC)を用いて周期境界をエミュレートできます。

Ansysでは、材料エンジニアやシミュレーションエンジニアの専門知識を結集して、お客様の材料設計プロセスのニーズに合わせて調整されたアプローチをご提案します。お客様の材料システムに最適なツールの組み合わせについては、当社のエンジニアリングチームにお問い合わせください。貴社のニーズに合うシミュレーションソリューションをご案内します。

関連リソース

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。