Case Study

-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

“The winning of the Ansys funding for curriculum development has been a significant factor in revitalising our programs use of contemporary tools in a holistic way. Ansys integration enables our students to explore deep fundamental and complex engineering problems and be aware that these problems do have solutions.”

— Bill McBride

Engineering Professor, The University of Newcastle

The University of Newcastle in New South Wales, Australia, embedded Ansys solutions into curriculum of multiple courses throughout the Mechanical Engineering degree program, with additional benefits for mechatronics and aerospace systems students at the University of Newcastle. With Ansys, part of Synopsys, students will gain consistent exposure and skill development in advanced computer-aided engineering (CAE) tools.

This approach modernizes engineering education by moving beyond traditional theorem derivation and manual problem-solving, which better aligns with industry needs. Graduates will develop practical proficiency in solving complex engineering problems, and educators can enhance learning by incorporating real-world applications.

Challenges

The University of Newcastle has partnered with Ansys for over 15 years and taught Ansys multiphysics in more recent years. While having high-quality tools is a key part of modern education, creating and accessing well-structured learning materials suited for undergraduate students, especially as learning shifts online, remains a challenge.

With support from the Ansys grant, university staff were able to dedicate time to developing online resources that explained the theory and guided students through the learning process over the course of a class. Knowledge of many major engineering software tools are required in university education, but giving students access to them in just one class isn’t enough to build confidence as users. By including a few core tools across multiple courses, students gain repeated exposure, enabling them to explore the tools more deeply and feel more confident when using them in later studies and real-world work.

“From an educator’s point of view, this approach moves us beyond simplified systems and allows us to demonstrate — and have students take part in solving — complex, real-world engineering problems,” Bill McBride, engineering professor, says.

Engineering Solutions

By updating the engineering curriculum to use a common software tool and interface, students now spend less time learning new platforms across different courses and more time exploring complex phenomena. While maintaining core theoretical foundations, the university also developed online learning resources that guide students through each class — supporting those for whom regular on-campus attendance is difficult in today’s environment.

This consistent approach across shared subjects allows for intentional upskilling and greater exposure to industry-relevant tools for students in the Mechatronics and Aerospace Systems degrees at Newcastle. Looking ahead, Professor McBride and team plan to adapt parts of the Aerospace Systems program to build on the Ansys skills students are now gaining.

The departments using Ansys tools and the courses they fit within are as follows:

Mechanical Engineering

- MECH3780 Fluid Mechanics 2 and CFD (and equivalent master’s course)

- MECH6480, Advanced Fluid Mechanics and CFD

- MECH3695, Heat Transfer

- MECH2110/3110, Mechanical Design

- MECH4410, Mechanics of Solids and FEA

- MECH4580, Advanced CAE

- MECH4841A/B Final Year Projects

Mechatronics Engineering

- ENGG4801A/B Final Year Projects

- MECH2110 (core Mechatronics course)

Aerospace Systems

- AERO4300, Airframe Systems

- ENGG4801A/B Final Year Projects

Medical Engineering

- MENG3100 Medical Engineering

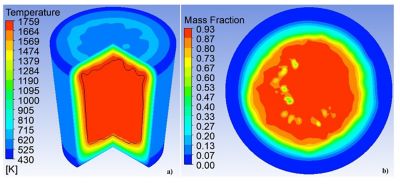

Simulation results for a 16-tonne steelmaking slag pot: a) temperature of the slag after cooling for 16 hours; b) liquid fraction at X-Z plane

Benefits

Engineers today are expected to have a wide range of skills and a strong foundation in core concepts. By reducing the mental load that comes with switching between multiple software tools, students become more proficient with Ansys software and build the deeper knowledge expected of professional engineers.

The goal is to equip graduates with the skills to use Ansys solutions for a wide variety of computational tasks. It’s no longer realistic to expect that future engineers will solve complex systems by hand, so integrating advanced CAE tools like Ansys software into the curriculum is essential for developing the modern, industry-ready engineer.

Stronger integration of tools like Ansys into the curriculum is essential for preparing students to meet the demands of modern engineering roles. This shift ensures that graduates leave not only with theoretical knowledge but also with practical, industry-relevant experience.

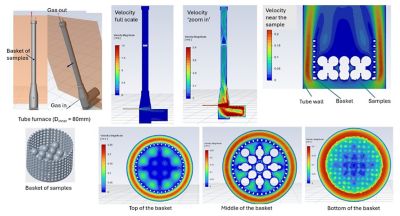

Flow distribution in a vertical tube furnace

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。