Digital Engineering

Digital engineering is impacting industrial processes and manufacturing in nearly every market, from automotive and aerospace to healthcare and energy

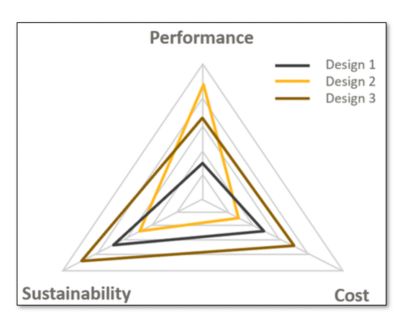

The fourth industrial revolution, known as Industry 4.0, marked the beginning of this digital transformation. Today, the trend continues with the fifth revolution, known as Industry 5.0, which aligns well with digital engineering and simulation’s role in it. Industry 4.0 focused on technology, but Industry 5.0 concentrates on the human–technology connection. It also emphasizes interaction and collaboration. The European Commission describes Industry 5.0 as more comprehensive than 4.0, highlighting sustainability, human-centricity, and resilience pillars. Digital engineering supports Industry 5.0 and its pillars in several ways.

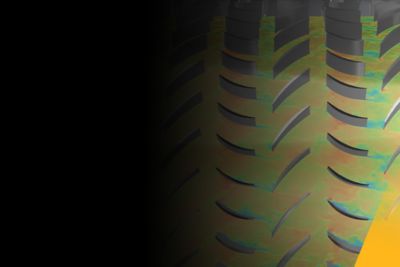

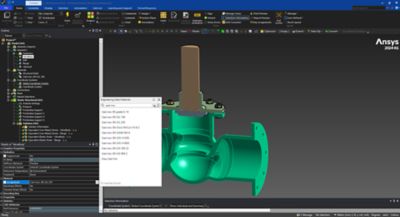

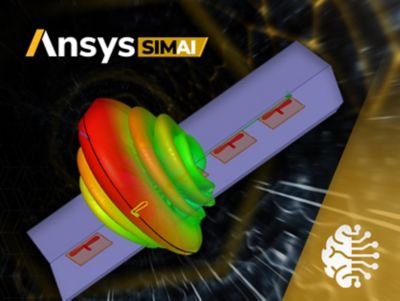

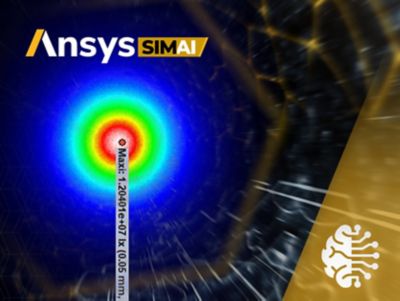

By integrating multiphysics simulation and related simulation methodologies, industrial equipment manufacturers and operators gain critical engineering insights to improve the behavior, performance, durability, and reliability of machinery, equipment, and infrastructure. In addition, virtual testing and prototyping accelerate design and development, which minimizes the time, cost, and material waste related to traditional physical methods