-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TOPIC DETAILS

What is Digital Engineering?

Digital engineering uses computational tools, digital models, and connected data to support the design, test, monitoring, and maintenance of modern-day cyber-physical systems. A digital engineering system consists of a holistic set of engineering practices developed to deal with complex systems, evolving technologies, and pressures to get products to market faster.

Engineering teams use digital engineering as a next-generation, model-based approach to product development and life cycle management. This approach aims to deliver timely contextual insights that support engineering decision-making. In other words, it provides the right information, at the right time, in the right context, and in the right format. Digital engineering is more than just applying digital transformation principles to engineering data. It creates an ecosystem that enables advanced technologies to:

- Model and simulate system behavior against requirements

- Implement automation

- Connect engineering disciplines across an organization

- Establish authoritative sources of truth for critical information

Why Digital Engineering Has Evolved

Engineers need timely, accurate information to make informed decisions.

The potential benefits of digital engineering make its definition and adoption a logical evolution of traditional hardware engineering practices with software dependencies. Traditional hardware development uses a waterfall methodology instead of the agile methods common in software development. Agile approaches often don’t work well for hardware development because of the complexity and interdependence of hardware systems.

However, the introduction of model-based systems engineering (MBSE) showed two ways to incorporate the advantages of agile methodologies. First, engineering teams could adopt a systems-level approach to modeling products against their requirements. Second, they could make information about the product more clearly defined and easier to access. Combined, this shift in strategy removed organizational and process dependencies.

The U.S. Department of Defense (DoD) saw these advantages and established a Digital Engineering Strategy in 2018 with these four specific goals:

- Formalize the development, integration, and use of models to inform enterprise and program decision-making

- Provide an enduring, authoritative source of truth

- Incorporate technological innovation to improve the engineering practice

- Establish supporting infrastructure and environments to perform activities, collaborate, and communicate across stakeholders

DoD Instruction 5000.97 further refined the strategy and encouraged the defense acquisition ecosystem to adopt digital engineering. Since this initiative, the aerospace and defense industry has increasingly embraced digital engineering for its inherent ability to manage cost, schedule, and risk effectively.

To better understand the drive for digital engineering, let’s break down the phrase “timely contextual engineering insight for engineering decision-making.”

- Timely: Because of growing competitive pressures and system complexity, organizations must not only design and get products to market faster but also increase uptime, validate and implement product improvements sooner, and diagnose and correct field failures more quickly. With these competitive demands, engineering teams no longer have the luxury of extended timelines to complete these tasks. By combingin model-based approaches with automation, authoritative sources of truth, and computational tools, a digital engineering environment can produce information much faster than traditional methods.

- Contextual: Modern simulation and the proliferation of sensors through the Internet of Things (IoT) have created an unprecedented wealth of data. However, for that data to be useful, decision-makers must understand its origin, relationship to other data, sources, and trustworthiness. Context provides this information by linking data to its as-designed, as-manufactured, and as-operated conditions.

- Engineering insight: Engineering, at its core, is the process of designing products to meet specifications and solving problems encountered during their life cycle. To do this effectively, engineers need information about every aspect of the product — its materials, operating environment, physical geometry, performance, durability, and more. Without these insights, teams must rely on guesswork and physical testing, an inefficient and expensive process. Digital engineering gives stakeholders across an enterprise access to the product-specific information they need to perform their roles effectively.

- Engineering decision-making: The reason teams need timely, contextual engineering insight is to make informed decisions. These can be made early in the product development process or at the end of a product's life, such as determining the best method of disposal. Digital engineering allows engineers to “shift left” by providing insights early on in the decision-making process, effectively reducing total life cycle costs.

In addition, digital engineering serves as an enabler for applying advanced technologies that improve insight and timeliness. Digital engineering plays a vital role in constructing a product’s digital thread — not just curating the necessary data but also defining the authoritative sources of truth for information connected through the thread.

When coupled with systems engineering and computational tools, especially MBSE, digital engineering gives real-time access to system-level digital models of the product. These allow what-if analyses, optimization, failure analysis, and predictive analytics that can span the entire product life cycle. By introducing rapidly advancing artificial intelligence (AI) technologies like machine learning (ML), neural networks, and large language models (LLMs), a digital engineering ecosystem can deliver even greater automation, more insightful predictive analytics — especially when using best-in-class physics-based simulation — and prescriptive maintenance.

Emerging Applications of Digital Engineering

A comprehensive, system-level approach to product development is the foundation of digital engineering.

Digital engineering systems consist of a collection of tools, processes, data sources, and infrastructure that provide a holistic and trusted end-to-end view of a system's product life cycle. Current implementations usually contain the following components:

Data Context, Classification, and Connection

Moving beyond data collection and data analytics is a critical step in adopting digital engineering. To create additional value from data, teams must first add contextual information around a product. They must then identify the authoritative sources of truth and connect the data to applications in an efficient, repeatable, and auditable manner. The digitized information can then be treated as accurate, protected from a cybersecurity standpoint, and accessed in a traceable way. This forms the foundation of the digital thread.

Digital Twins

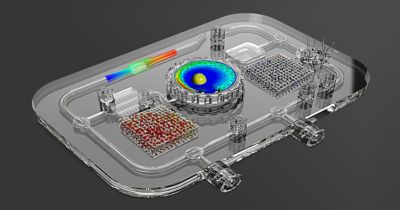

A digital twin of a bioreactor that uses multiphysics simulation

Digital representations of an entire system, its components, or its subsystems provide insights that go beyond static data. Often referred to as a digital twin, these models allow engineers to change operating conditions, geometric parameters, and nonengineering inputs to see how the system will respond under as-designed and as-operated conditions. Digital twins can consist of, but are not limited to:

- Computer-aided design (CAD) 3D models of geometry

- Model-based design

- 0D/1D/3D simulation models

- Lookup tables generated from curated data

- Reduced-order models (ROMs) generated from detailed simulations or test data

- Business and supply chain representations

Process Automation

To streamline the product development process, organizations adopting digital engineering implement automation and orchestration. These simplify and speed up access to information in the digital thread, execute computational models, and add data to the system. Automation also enables access for nonexperts in a given discipline, which reinforces the goal of getting the right information to the right people at the right time.

Organizational Adoption and Paradigm Shift

When an organization implements digital engineering, behavioral changes are as important as technical ones. Every stakeholder involved in a product's life cycle must understand and adopt a data-driven, system-level approach to product development. The enterprise should promote both collaboration and innovation across disciplines, secure visible support from leadership, establish strict data governance practices, and encourage agile methodologies.

Open Architectures for Tools

The implementation team must ensure any tools in their digital engineering system use an open architecture that promotes efficient, traceable, repeatable, interoperable, collaborative, and accurate access to data. Siloed tools that operate in their own closed ecosystem — rather than adopting modern industry-standard application programming interfaces (APIs) — prevent organizations from benefiting from some of the advantages of digital engineering.

Example Use Cases for Effective Digital Engineering Implementation

Metasurface geometry with three types of meta-atom (triangle, round, and square pillars)

Digital engineering can enhance any organization's product life cycle processes, regardless of industry. However, industries with strong regulatory requirements, complex electromechanical systems, and rigorous performance goals benefit the most. Aerospace, healthcare, and automotive offer some of the strongest use cases.

Battery Gigafactories

Rapid technological advances and exponential growth in battery demand for aerospace, energy, and automotive applications are driving manufacturers to adopt digital engineering in their “gigafactories” — a recent term some companies have adopted to describe their battery and electric vehicle (EV) factories.

For example, Honeywell Process Solutions offers automation systems built using digital engineering. These systems combine real-time data and physics-based simulation to design production lines that dynamically adjust to changing conditions. Using this approach can help customers realize higher yields, lower costs, and greater energy efficiency.

Software-Defined Vehicles

Software-defined vehicles are revolutionizing the automotive industry.

In the automotive space, smart systems controlled by software are changing the competitive landscape. Many automotive manufacturers use digital engineering to help them move to software-defined vehicles (SDVs) faster and with fewer problems in the field. Digital engineering allows original equipment manufacturers (OEMs) and their suppliers to collaborate on the design, validation, and implementation of their SDV vision. Many implementations use their digital engineering platform to:

- Include AI in their solutions

- Overcome the organizational barriers between electrical, mechanical, and software engineering

- Improve designs with multiphysics optimization

- Incorporate information from other disciplines

- Improve the robustness of their embedded software

Testing Medical Devices In Silico

In healthcare and other industries, in silico testing refers to the use of digital models in product development. This is in contrast with in vivo (in the body) and in vitro (outside the body, such as in a laboratory setting) testing. With the introduction of digital engineering, the entire product development process becomes better aligned with the stringent regulatory requirements of medical device development and approval. Engineering teams can maintain a single, documented source of truth, speed up their development process, and provide verification and validation data to regulatory bodies.

Enhancing Digital Engineering With Modeling and Simulation

Modeling and simulation tools extend digital engineering beyond data management, enabling engineering teams to efficiently explore product performance using high-fidelity, physics-based analysis. Simulation also provides actionable insights earlier in the development process. A well-implemented digital engineering system should use simulation tools with the following characteristics:

Open Input/Output of Data and Automation Support

Effective digital engineering requires integration and automation that enable outside tools to extract results, incorporate input from trusted sources, and manage active simulation models. The PyAnsys pythonic access tool for Ansys software is a well-documented solution that supports industry-standard file formats. Additionally, Ansys Minerva simulation process and data management software provides a single source of truth for controlling and accessing simulation data and models.

An open platform also supports the integration of other disciplines into your simulations. For example, a materials information solution such as the Ansys Granta product collection can provide traceability and ensure a single source of truth for material properties. Openness also enables optimization tools like Ansys optiSLang process integration and design optimization software, as well as emerging artificial intelligence (AI) solutions like the Ansys SimAI cloud-enabled AI platform.

Physics-Based and Multiphysics Simulation

The computational tools in digital engineering solutions must be accurate and grounded in the physics they represent. Best-in-class tools from Ansys, part of Synopsys, deliver component and subsystem-level simulations:

Because most products involve multiple physics, Ansys employs a multiphysics approach to understanding structural, thermal, electrical, electromagnetic, and optical interactions in a virtual representation of a product.

System-Level Simulation

Once the component and subsystems are accurately modeled, the next step is to deploy system-level simulation tools. Solutions like Ansys ModelCenter MBSE software enable engineers to fully explore product performance from a systems perspective. For products that undergo multiple missions or complex interactions over time, a digital mission engineering simulation platform like Ansys Systems Tool Kit (STK) software offers comprehensive mission planning, visualization, and multiphysics interaction capabilities in a single platform.

Finally, a tool like Ansys Twin Builder simulation-based digital twin platform can be used across teams to create and manage digital twins to virtually represent products and processes.

Integration of Embedded System Software

Most modern products incorporate embedded software, either within sensors or to manage a product itself. This highlights the need for tools that facilitate rapid software development and testing within the broader system's context. The Ansys SCADE suite is an example of a software development platform that enables hardware-in-the-loop and software-in-the-loop testing.

Fast, Flexible Solvers

Flexible simulation platforms enable enterprises to leverage high-performance cloud platforms.

Effective digital engineering implementations need fast solvers to run multiple scenarios across hardware solutions and deliver timely insights. For example, the Ansys Fluent native GPU solver can model fluid behavior at speeds that far exceed simulating on CPUs. Additionally, the Ansys Cloud collection offers the flexibility, speed, and affordability of cloud computing to bring advanced simulation to any user.

Related Resources

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.