-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

November 30, 2021

Getting Started with Digital Twins

Build, validate, and deploy digital twins with Ansys software

In manufacturing, equipment care and maintenance is critical for efficiency, product quality, and safety. To accurately predict the behavior of complex and large-scale assets common in factories, companies embracing “industry 4.0” innovations are moving away from expensive and time-consuming physical prototyping. Today, manufacturers are protecting their most valuable assets with digital twins.

What is a Digital Twin?

A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity.* This allows companies to monitor what’s happening inside the physical asset in real-time. By providing a holistic view of real-time behavior in a real-world environment mapped to a constantly updated virtual model, digital twins make it possible to anticipate maintenance needs, optimize performance and avoid costly failures.

* This definition is provided by the Digital Twin Consortium, the authority on Digital Twins, of which Ansys is a founding member.

How Do Digital Twins Work?

With digital twins, companies can predict the future and anticipate how changes in design, process, or environment will affect how an asset functions in the real world. Performance data from the physical equipment is fed to the simulation as it happens, so issues can be addressed immediately, before they affect system performance, curbing downtime to save on overall production costs.

Advantages and Benefits of Using Digital Twins

- Risk assessment: Design, install, or test a virtual model of a machine or system configuration to know if it will work before it is built.

- Predictive and prescriptive maintenance: Anticipate issues based on different environmental pressures and scenarios.

- Production optimization: Perform what-ifs to evaluate upgrade considerations before choosing a solution.

- Financial confidence: Identify and calculate the actual costs of materials and labor to inform better financial decisions.

- Real-time asset monitoring: Observe and predict the behavior of the installation in real-time.

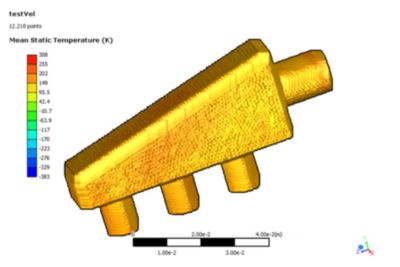

Reduced-order model (ROM) of a battery

What Industries Use Digital Twins?

Digital twins are currently being used across many industries, including aerospace, automotive, manufacturing, healthcare, buildings and infrastructure, or oil and gas, to analyze data across performance scenarios.

Digital Twin Examples

Process and Product Optimization: Replicating Real-Life Operating Conditions with a Digital Twin

For applications that require tight control in the flow of raw materials, using a digital twin during the production process can accurately predict the quality of the end product, enabling manufacturers to make more informed decisions.

Using Ansys Digital Twin technology, KÄRCHER simulated a smaller battery pack to reduce weight and heat, giving them insight into the entire system in minutes, rather than days. It also provided the additional flexibility their engineers needed to consider things like different battery cells or battery pack housing materials under real-life installation situations. Read the story

Equipment Maintenance: Digital Twin Enables Real-time Analysis

Unplanned downtime can cost tens of thousands of dollars per hour. A simulation-based digital twin can accurately predict equipment stresses and hot spots to prevent unanticipated maintenance needs during a production cycle.

Using an Ansys simulation-based digital twin, Electronic Cooling Solutions identified the critical design elements required for an effective thermal monitoring system and significantly reduced the calculation time from weeks to hours. This resulted in a significant time-to-market reduction. Read the story

Carbon Reduction: Digital Twins Anticipate and Minimize Energy Consumption

As companies work to have a zero-carbon footprint, a digital twin can test and validate carbon reduction options to see which opportunities are most appealing.

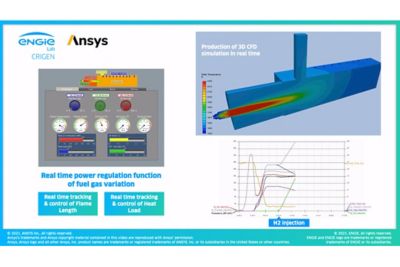

To guide its customers toward a greener and more ecological energy source, ENGIE Lab CRIGEN relies on Ansys' digital twin technology to accelerate the zero-carbon energy transition for its customers. Read the story

Product Sales: Reinvent Sales with a Digital Twin

Providing a precise quote for large equipment can require weeks and multiple customer visits. A digital twin of a proposed installation can accurately quote performance and cost quickly and easily.

Real-time power regulation function of fuel gas variation

KAESER connects engineering simulations with sales processes to create a next-generation sales experience for customers.

How to Design a Digital Twin

1. Identify the right asset for testing: Choose an asset (or process) that is very expensive ($100K+), or the downtime of the asset due to failure asset is very expensive. For example: A hydraulic turbine engine is a single asset that can cost millions of dollars. Or, in the oil and gas industry, the failure of an electric submersible pump can cause an unplanned shutdown in offshore operations, resulting in tens of millions of dollars in deferred revenue.

2. Create a small proof of concept: See how the asset you have chosen could benefit from a digital twin by getting a free trial version of Ansys Twin Builder. Your starter package includes all the software and libraries, plus the training and support you need. Simply fill out the form below to contact an Ansys representative to start the process.

Export deployment Digital Twins with Twin Deployer

3. Share your results. A member of the Ansys ACE team can help you analyze your data and create a presentation to share with your leadership team that will assess opportunities for scaling Twin Builder across your company’s assets.

The Future of Digital Twins

As digital twins become more integrated across industries, new features and capabilities are being constantly added. Now is the time to get started with digital twins so your company is up to speed and prepared to capitalize on the future.