Case Study

-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

“Ansys PyMAPDL enabled us to automate thousands of high-fidelity simulations across a vast design space, which would have been infeasible manually. By integrating Ansys finite element analysis (FEA) solutions with our Python-based optimization framework, we reduced iteration time by over 90% and discovered a nonintuitive metamaterial design with experimentally validated auxetic and isotropic behavior. This level of scalability was critical to the success of our research.”

— Timon Meier

Ph.D. Candidate / University of California, Berkeley

The Laser Thermal Laboratory at the University of California, Berkeley (UC Berkeley), developed a fully automated inverse design framework to create metamaterials with simultaneous auxetic and isotropic behavior. Using Ansys PyMAPDL, engineers performed high-throughput finite element analysis (FEA) simulations coupled with multi-objective optimization to evaluate thousands of lattice configurations. The optimized structures were then fabricated using multiphoton lithography and experimentally validated through in situ micro-indentation, confirming the accuracy of the simulated elastic behavior.

The project’s goal was to achieve simultaneous auxetic and isotropic mechanical behavior — two typically conflicting properties rarely observed together. Auxeticity enables superior energy absorption, impact resistance, and the ability to withstand significant deformation without fracturing. In contrast, isotropy provides consistent mechanical performance in all directions, making it valuable for applications with unknown or variable loading conditions. This combination is ideal for ultralight, impact-resistant materials, biomedical implants, and aerospace structures subjected to complex, multidirectional forces.

Challenges

The team at the Laser Thermal Laboratory aimed to design metamaterials with both auxetic and isotropic properties, which created a highly nonintuitive and computationally complex challenge. Simulation was critical in exploring thousands of design permutations without costly trial and error. The team chose Ansys PyMAPDL for its scripting flexibility, integration with Python-based optimization (NSGA-II), and reliable FEA capabilities. Full automation within a Python environment enabled the team to seamlessly integrate geometry generation, simulation, and optimization without manual intervention.

Figure 1. Overview of the design and validation workflow: (a) Visualization of the multi-objective optimization problem targeting isotropic and auxetic lattice behavior. The stiffness map shows the transition from an arbitrary initial shape (top right) to a sphere (bottom left), with color shifts indicating a change from high Poisson’s ratio (red) to auxeticity (blue). (b) High-resolution HIM image of the optimized design, highlighting distinct unit cell states resulting from the PyMAPDL-based inverse design. (c) SEM frame from in situ compression testing using a PI-87 Picoindenter, capturing the real-time mechanical response of the fabricated structure.

Engineering Solutions

- Automated the full inverse design workflow in Python, integrating Ansys PyMAPDL with the pymoo optimization library (NSGA-II) for multi-objective search targeting isotropy and auxeticity

- Programmatically created thousands of 3D lattice geometries, defined unit cell combinations, and applied boundary conditions via parametric scripting in PyMAPDL

- Performed customized linear static FEA simulations to extract directional elastic properties (C₁₁, C₁₂, C₄₄) from each lattice configuration

- Iteratively refined designs based on simulation results to efficiently converge toward auxetic and isotropic mechanical behavior

- Explored a vast, discrete design space of ~10 billion configurations with no manual input, made possible by seamless Python-based automation

- Validated the optimized design experimentally via multiphoton lithography and in situ micro-indentation, showing strong agreement with FEA predictions.

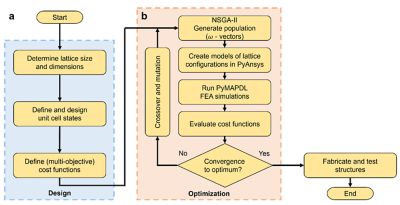

Figure 2. Fully automated design and optimization framework: (a) Initial setup defines geometry, boundary conditions, and target objectives for isotropy and auxeticity. (b) Workflow automates FEA simulations via PyMAPDL and uses NSGA-II for multi-objective optimization. Final structures are fabricated and experimentally validated.

Benefits

- Enabled exploration of a design space with ~10⁹ lattice configurations, which would be infeasible through physical prototyping or manual simulation

- Reduced per-iteration time to ~5 minutes, which enabled more than 2,000 simulations in under a week on a single workstation

- Achieved >90% time savings compared to manual FEA setup and analysis with a flexible, scriptable interface to Ansys Mechanical software

- Accelerated the team’s discovery of a nonintuitive auxetic and isotropic structure, confirmed experimentally with <8% deviation in elastic properties

- Provided a reproducible, scalable framework for future metamaterial design challenges across length scales and applications

- Supported the design of next-generation metamaterials for aerospace, biomedical, and protective systems requiring lightweight construction, high energy absorption, and uniform mechanical response under unpredictable loading

- Fully automated geometry creation, boundary condition setup, and post-processing while leveraging the broader Python ecosystem for data handling, visualization, and workflow orchestration

- Offered a UI-agnostic, open-source simulation framework that can be easily adapted to optimize a wide range of mechanical properties beyond auxeticity and isotropy, such as stiffness, damping, energy dissipation, or failure control, by simply redefining the cost functions

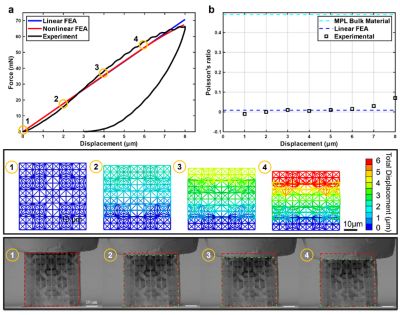

Figure 3. Experimental validation of optimized design: (a) Representative force–displacement curves comparing simulation (linear and nonlinear FEA performed in PyMAPDL) and experimental compression tests. Insets show corresponding deformation states. (b) Comparison of Poisson’s ratio under compression from simulations and experiments. Results confirm auxetic behavior close to the optimization goal of zero.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.