-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

Discover how WITTENSTEIN upped its development game with support from CADFEM and Ansys.

What happens when you automate a multiphysics simulation workflow with help from PyAnsys? For Kai Schneider, the outcome was better-quality electric motor designs that can deliver higher levels of power density and efficiency more quickly, along with the opportunity to accumulate more expertise to support his customers’ hybrid electric vehicle (HEV) initiatives.

“Since automating our workflow, we have expanded our knowledge of what we can do with our cooling system and what we should change,” he adds. “We have made new discoveries that can be used for other projects in this short time on how to apply simulation in different ways to find new ideas, to work together in the future to see what we can do with models of all sizes in a way that will change the way we look at entire vehicle systems.”

Schneider works for WITTENSTEIN cyber motor GmbH, a subsidiary of WITTENSTEIN SE, as a development engineer. They design, produce, and sell technologically advanced servo motors and drive electronics, as well as complete mechatronic drive systems, primarily for industrial, special and automotive applications.

With support from Daniel Soukup, solution architect at Ansys Apex Channel Partner CADFEM Germany GmbH, Schneider’s team was able to automate and accelerate design analysis to quickly respond to customer requests for novel electric motor technology. Soukup and the CADFEM team connect WITTENSTEIN with the Ansys software, training, and support needed to implement its motor designs.

“These customer-specific developments need a starting point,” says Soukup. “It’s where you need some expertise, some capacity to do it. And this is where CADFEM and simulation are particularly valuable for Ansys customers.”

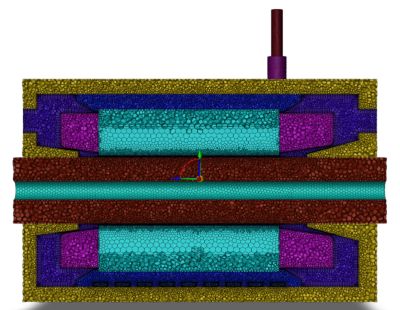

Mesh generated with the automated PyFluent setup, courtesy of CADFEM

Maximizing Efficiency at the Intersection of Temperature and Power Delivery

WITTENSTEIN sells off-the-shelf electric motor solutions that are often adapted to satisfy individual customer requirements. The company is focused on achieving a high level of power density for its motors through the design of cooling concepts to realize the best performance, particularly for the automotive space.

According to Schneider, achieving this requires motor development on the border of overheating and continuous power. Installation space is often very limited, therefore the cooling system must be optimized to get the best out of the available installation space.

“Finding that balance between temperature and power delivery is challenging, especially in the automotive sector,” he says. “There, we have high temperatures in the coolant itself, low pressure drop requirements, and little space. We need a system or program that can calculate these thresholds within our prescribed development timeline.”

However, before WITTENSTEIN can produce a prototype of a motor and test it, they must clarify whether the cooling concept is a good one or if refinement is needed for a similar cooling system already in its portfolio.

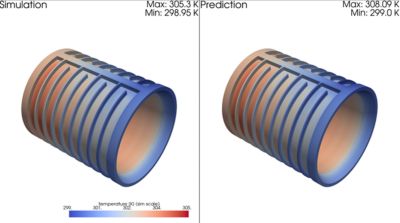

Comparison of simulated and AI-predicted temperature distribution on the heat sink, courtesy of CADFEM

One Automated Toolchain To Keep the Concepts Flowing

One of the immediate benefits of simulation is the ability to achieve an optimal, highly performant motor cooling design faster. WITTENSTEIN and CADFEM routinely use Ansys tools to go into simulation loops to analyze a specific design, then determine if any improvements are warranted.

To develop cooling systems more efficiently, a combination of an extremely fast graphics processing unit (GPU) solver, powerful geometry modeling capabilities, and systematic parametric design studies was initially used to accelerate electric motor cooling design development.

Design optimization is achieved even faster through several Ansys simulation tools and solvers, specifically:

- Ansys Fluent fluid simulation software for the flow of the cooling system and the temperatures that occur in the materials in the housings

- Ansys Discovery 3D product simulation software to define geometric parameters for simulation automation to generate variants while preserving the original design

These tools form the basis of a CADFEM automated simulation workflow that is easy to set up and can be applied to different areas and applications with few adjustments. After developing the workflow locally on a desktop, scalability can be easily achieved by leveraging virtual machines in the cloud to run a large number of simulations simultaneously.

“In the past, this process could be quite time-consuming, especially if you have one of these manual iterations where you need to make some adaptations, then run a new simulation,” Schneider says. “Of course, this activity is crucial to design enhancements. At the same time, we also run the risk of not fulfilling customer timelines. We are really limited by time to market.”

Initially, combining an extremely fast graphics processing unit (GPU) solver with powerful geometry modeling capabilities and systematic parametric design studies significantly accelerated electric motor cooling design development.

Using simulation, a 10% reduction in fluid temperature was achieved, while cutting pressure loss of the cooling system of an electric vehicle motor roughly in half.

Variety of the generated and simulated cooling designs, courtesy of CADFEM

Going “Off Script” With PyAnsys for More Modeling Flexibility

With the introduction of PyAnsys into WITTENSTEIN’s existing workflow mentioned above, powerful new capabilities were unlocked to access Ansys software, streamlining the development and automation of sophisticated simulation workflows. CADFEM was able to successfully automate AI data generation for motor cooling analysis via PyFluent and Ansys optiSLang software to really speed things up.

WITTENSTEIN wanted to discern how to profit from AI models that predict behavior on new geometry without a full simulation run, early in development.

Specifically, Ansys optiSLang software was used to combine a parametrized geometry created in Ansys Discovery software with an automated Ansys PyFluent setup. Generation and simulation of new variants with export of results to the result format for presentation of data to AI could then be done very easily and fast. Because this workflow could be controlled by parameters, CADFEM generated many variants, without relying on available real data involving fewer data points and a variation that was too different for a first AI benchmark.

“PyAnsys is all Python, providing the simplicity needed for creating variants,” says Soukup. “It results in a workflow that is reliable and robust to automate. Having automated our geometry generation with our Fluent setup, we can also export data for use inside an AI model later on. We got our workflow template, ultimately enhancing our design capabilities even more.”

So Many Designs in So Little Time

For Schneider, speed was one of the biggest benefits of using Ansys tools to automate this workflow. It enables WITTENSTEIN to quickly pivot to meet customer requirements in near real time.

“From my perspective,” he says, “we had a lot of designs that we could simulate — basically more than 70 we can now reference for performance as a result of our efforts, specifically how the coolant is flowing through the motor. After automating the entire workflow, we simulated so many designs within such a short time, and with different parameters. That was really surprising for me.”

WITTENSTEIN and CADFEM have a long history of success in working together to optimize electric motor technology.

Download the case study “WITTENSTEIN Breaks New Ground in Designing Cooling Concepts for Electric Motors” for more information.

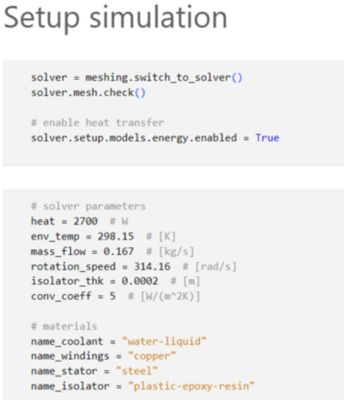

Parameterized PyFluent script to easily change boundary conditions in the simulation, courtesy of CADFEM

Just for you. We have some additional resources you may enjoy.

“Since automating our workflow, we have expanded our knowledge of what we can do with our cooling system and what we should change.”

— Kai Schneider, development engineer, WITTENSTEIN cyber motor GmbH

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.