-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

October 4, 2018

Making Wireless Multigigabit Data Transfer Reliable with Simulation

The demand for wireless communications with high data transfer rates is growing.

Consumers want wireless 4K video streams, virtual reality, cloud backups and docking. However, it's a challenge to offer these data transfer hogs wirelessly.

Peraso aims to overcome this challenge with their W120 WiGig chipset. This device offers multigigabit data transfers, is as small as a thumb-drive and plugs into a USB 3.0 port.

The chipset uses the Wi-Fi Alliance’s new wireless networking standard, WiGig.

This standard adds a 60 GHz communication band to the 2.4 and 5 GHz bands used by traditional Wi-Fi. The result is higher data rates, lower latency and dynamic session transferring with multiband devices.

In theory, the W120 WiGig chipset could run some of the heaviest data transfer hogs on the market without a cord. Peraso’s challenge is to design a way for the chipset to dissipate all the heat it generates.

Peraso uses the multiphysics capabilities within the Ansys Electronics portfolio to predict the Joule heating and the subsequent heat flow effects of the W120 WiGig chipset. This information helps them iterate their designs to better dissipate the heat.

How to Design High Speed Wireless Chips That Don’t Overheat

Systems designers know that asking for high-power transmitters in a compact and cost-effective enclosure translates into a thermal challenge. The W120 WiGig chipset is no different.

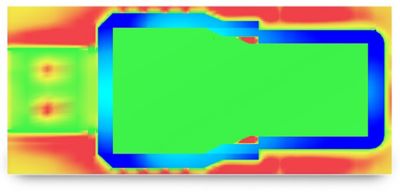

A cross section temperature map of the W120 WiGig chipset’s PCB.

The map shows hot spots where air flow is constrained by

narrow gaps between the PCB and enclosure.

The chipset includes active/passive components and two main chips that are mounted on a printed circuit board (PCB). The system reaches considerably high temperatures due to the Joule heating effect.

To dissipate this heat, design engineers include a large heat sink that connects only to the chips and a smaller one that connects only to the PCB. The system is also enclosed in a casing with limited openings.

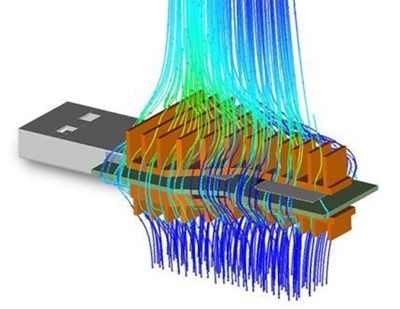

Simulation of the air flow around the W120 WiGig chipset without an enclosure. Simulation was made using Ansys Icepak.Simulation of the air flow around the W120 WiGig chipset without an enclosure. Simulation was made using Ansys Icepak.

Traditionally, optimizing this set up takes a lot of trial and error as measuring the air flow within the enclosure would be challenging.

Instead, Peraso uses Ansys SIwave to simulate the Joule heating effects of the system. This heat map is transferred to Ansys Icepak, which then simulates the current heat flow, orthotropic thermal conductivity, heat sources and other thermal effects.

This multiphysics simulation enables Peraso to predict the heat distribution and the temperature at every point of the W120 WiGig chipset.

From there, Peraso engineers iterate their designs until they reached their coolest setup.

This simulation led design tactic helps Peraso optimize their system until they reached a heat transfer balance they need.

Simulation of the air flow around the W120 WiGig chipset without an enclosure. Simulation was made using ANSYS Icepak.