-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

June 20, 2022

Hitting the Trail: How Electric Vehicle Software is Democratizing Off-Road Adventure

Electric vehicles (EVs) are already reshaping everything we know about driving, and it’s anyone’s guess how much change we can expect to see in the near future. Biometric identification, personal voice assistants, and an autonomous parking feature that can help you find a good parking spot are all on the table, but what’s ahead for those of us who just love to drive? Despite these trends, there’s still significant interest in recreational cruising, which is why Sam Poirier, co-founder and CEO of Potential Motors, is taking electrification off-road and enhancing the driving experience through software.

It was Poirier’s initial interest in EV conversions that would set him on a path to something much bigger. Through this work, Poirier saw a big shift happening in the general mobility space toward electrification that extended beyond hardware, and he decided to capitalize on that to take the technology off-road.

Poirier now wants to enhance, rather than diminish, the interaction off-road between the driver and the environment. The trick to this is adding a layer of software to co-pilot the vehicle in extreme conditions. The software should respond based on the skill level of the driver without diminishing the feeling of control that comes from navigating through mud bogs and over rocky terrain. Gathering data through Ansys simulation software was an important part of interpreting what this connected experience should be.

“One of the things we're working on is proactive control over the suspension, for example, and changing the dampening in each corner of the vehicle as you pass over different types of terrain,” says Poirier. “Today, you can either do that with a button, or you have to get out and manually change your suspension, which requires a certain level of skill. There will be extremes in either direction, depending on the driver, so having software that enables driving options of varying degrees based on the user is important.”

Ansys Startup Program Supports EV Software Development for Cleaner, Quieter Recreation

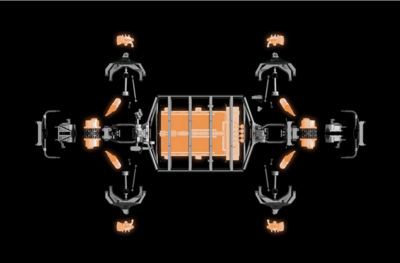

EVs require greater levels of software control over different components, such as suspension actuation, steering, and torque vectoring (differential technology for varying torque within an electronics system), which requires control over different motors in the vehicle. At the same time, automotive manufacturers are focused on improving performance in adverse conditions while reducing hardware complexity. With help from the Ansys Startup Program, Potential Motors is developing an advanced vehicle control software for electric off-road vehicles that improves driving in adverse conditions while centralizing and simplifying EV architecture through holistic control of the drivetrain.

Poirier describes the software as the “brain” of off-road vehicles and believes it is the key to electrifying off-road experiences. As with on-road applications, he believes his simple, scalable software program will lead to more efficient enablement of new off-road features and performance enhancements supporting cleaner, quieter outdoor adventures.

Lower control arm mesh

“What’s really driving vehicle innovation in electrification is software,” says Poirier. “And what’s really interesting about that is the demand for experience in this realm — and that we had already started to build a team with a ton of experience there. We take it a step further using software to improve driving in the most extreme conditions that will open up opportunities for recreational off-roading to more people. It’s also a great test bench for original equipment manufacturers (OEMs) in the development of more traditional on-road EV applications.”

Simulating Up and Over Big Rocks and Through Mud Bogs

Confident testing of load cases before release was central to overall software development. Off-road vehicles need to be able to withstand some pretty significant loads while driving because they’ll be used to go up and over rocks and back down again, putting a lot of stress on the suspension and frame. Potential Motors has been able to model all of that with the tools that are available through the Ansys Startup Program and ensure that the structure of the vehicle will hold up under different loading conditions.

Access to Ansys software was extremely valuable in testing load cases and other areas fundamental to advancing the overall vehicle design. It gave Potential Motors’ engineers an understanding of how the vehicle would survive the rugged off-road environment. Without simulation, making such determinations would involve hours of hand calculations to check and validate that a design was appropriate for off-road use. Actual validation touched on multiple critical vehicle aspects, including the chassis, suspension components, battery pack design, and steering system, and extended to other aspects such as wire harnessing and occupant layout.

Potential Motors used many Ansys tools to achieve their objectives during validation, including:

- Ansys SpaceClaim, a user-friendly 3D computer-aided design (CAD) modeling software to enable easy geometry preparation for simulation of the suspension, chassis, and related components.

- Ansys Workbench, a simulation integration platform to help the team keep all design iterations in one place.

- Ansys Mechanical finite element analysis (FEA) software to help identify thermal elements available in the user interface without having to use commands.

- Ansys Fluent fluid simulation software designed to help them solve large, complex problems.

- Successful data sharing with SolidWorks.

Exploded view of the Potential Motors platform with components highlighted

Engineers using simulation at Potential Motors run six-core Intel i7 processors with 64 GB of RAM or less from a shared workstation with an AMD Ryzen Threadripper 3990X with 64-cores and 128 GB of RAM, along with Amazon Web Services (AWS), if needed.

Ansys Mechanical Puts EV Battery Technology to the Test

Potential Motors has mostly benefited from Ansys Mechanical so far, given that the focus of their work to date has been on assessing loading on the vehicle, including the impacts of loading on the battery pack. As part of their off-road vehicle design, the vehicle battery modules were mounted to the actual battery enclosure.

The battery pack enclosure involves a box with all the electronics and battery modules sitting within it. Each of the battery modules within this box is separate and needs to be mounted down, then connected to the busbars, which are solid bars used for electrical current distribution between the incoming source and outgoing terminals of the vehicle’s electrical distribution system. In this scenario, the surrounding wiring and electrical components also need to be considered. It’s important that the battery pack and its related components remain still while the vehicle is in motion to prevent shorting that leads to thermal runaway, which in turn can create smoke, fire, and possibly even vehicle explosions.

“Basically, we were able to do a lot of the analysis up front, and actually went through a couple of iterations of the design around how the battery packs were going to be mounted,” says Poirier. “We came up with an initial design before realizing that it did not meet the requirements for the loading that it was going to undergo. Using Ansys simulation software helped us do a redesign that was more appropriate to our overall design strategy.”

Potential Motors' simulation expert works with various simulation tools.

Ansys Mechanical Sorts Out Load Displacement in Anti-Roll Bar Design

Vincius de Almeida Lima, vehicle simulation engineer at Potential Motors, is intimately familiar with Ansys simulation software. He used it to understand maximum deflection of their anti-roll bar (ARB) design. Essentially, he wanted to find out the degree an element of the suspension system could be displaced under a load, which can happen in certain dynamic off-road conditions.

To do this, Lima first ran a full vehicle dynamics model in a CarSim environment to get the maximum suspension displacement at the wheel center. Data coming from this model was then fed to a detailed subsystem model in Mechanical, where displacement or acceleration could then be applied — depending on inertial effects — as boundary conditions to an FEA of the full suspension system (arms, steering, and ARB or torsion-spring modeled).

“The ARB is integral to the suspension geometry — it connects all suspension elements shared between wheels on the same axle,” says Lima. “Most articulations in our model use Ansys Mechanical’s Rigid Body Dynamics solver during the first iteration. If I notice any stress concentration, I can easily remodel the contact region to arrive at a more feasible design.”

Potential Motors is excited to join the second wave of electrification in powersports as an innovator and major force in off-road EV technology, with support from the Ansys Startup Program. One of the team’s biggest challenges is modeling off-road environments. To overcome it involves a mix of simulation and real-world data: collecting data using an off-road EV prototype through real-world testing, then using that information to validate their simulations.

Learn more about the Ansys Startup Program and Ansys electrification solutions.