-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

Cleaning equipment and systems design company Kärcher built one-click test data import plug-ins using the Ansys Granta MI Scripting Tool Kit for Python.

Digitizing data from multiple sources can be challenging due to the wide variety of existing formats. For materials measurement and test data, digitization would require transferring the data from the test machine’s software to an intermediate format (often as a PDF or Excel file) to the materials data management system. Very often, extensive processing is required to modify the data to fit the system schema and prepare it for downstream use, such as in finite element analysis (FEA) simulation. This manual process is not only time-consuming but also error-prone, as the person inputting the data must ensure they are adding it to the appropriate material in the system.

Some types of data can also be more difficult to transfer than others. “Transferring data from test machines to a materials data management system can be frustrating as every system uses its own format,” says Daniel Carmine Manocchio, manager of the Kärcher Materials Laboratory. Functional data refers to the properties of materials that change in response to operating parameters, such as temperature. Manually entering this data type can lead to mistakes, resulting in duplicate simulations, wasted time spent debugging models, and decreased engineering productivity.

The objective: reduce errors and save time by directly connecting the test machine with the data management system.

Connecting Diverse Systems for Effortless Data Transfer

A key component of a materials management system is its ability to connect to other enterprise systems. It must be able to import and gather information from upstream sources such as file systems, software systems, and other databases. It also needs to serve this information to downstream users such as designers, product engineers, and simulation engineers via a user interface, a direct connection with another enterprise system, an export, or an application programming interface (API) connection.

By connecting previously siloed teams with a single, centralized source of input material data, engineers can spend less time searching for materials information and more time working on developing and optimizing their products, which improves product quality and leads to faster time to market.

The Ansys Granta MI Enterprise materials data management system can connect natively with many computer-aided design (CAD), product life cycle management (PLM), and engineering simulation systems that follow an open ecosystem architecture. Designers and engineers can use native CAD, PLM, and simulation plug-ins called Materials Gateways to search for materials, visualize their properties, assign them to components, manage lists of their favorite materials, and subscribe to approved published materials lists without ever leaving their preferred engineering tool.

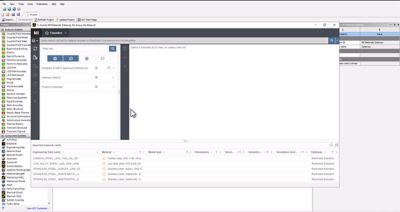

The Ansys Granta MI Materials Gateway window within the Ansys Workbench simulation integration platform

When a native connection does not exist, a custom connection can be developed via the Scripting Tool Kit, an API provided by the Granta MI Enterprise platform that can be used to export, analyze, transform, modify, and import data into the software. With the power of Python and the Scripting Tool Kit, advanced users can create integrations with whatever software they wish, enabling them to streamline bespoke, company-specific processes and reduce time wasted on manual operations.

Building a Custom One-Click Integration

Kärcher uses the Granta MI Enterprise platform to manage their materials data. The company’s materials data and information represent valuable intellectual property, as Kärcher’s plastics database is significantly enhanced with company-specific data. Kärcher manufactures in plants around the world and demonstrates a strong commitment to local suppliers for parts and materials. “Managing these parts and the materials that they are made of without spending too much time and effort requires a complete and customizable database like Granta MI software,” says Manocchio, highlighting the importance of using a gold source of truth to efficiently trace where their materials information comes from and which materials are used on which products.

The Kärcher Materials Laboratory performs more than 500 materials tests per year, with data containing a multitude of attributes and metadata. This includes functional data, which can be tricky to import manually and may lead to errors. By directly connecting the test machine software with the Granta MI platform, the process was automated, eliminating errors and saving engineering time and effort.

A dedicated Granta import button was created to host the one-click plug-in for importing test data in the Granta MI platform.

To automate this process, Kärcher combined the API of the test software with the Scripting Tool Kit to create a one-click plug-in for the test software. Once a materials engineer has completed a test, they can simply click on the custom button in the test software interface to automatically process and transfer the data into the Granta MI platform. A crucial part of the process is identifying the corresponding material record in the Granta MI platform so that the test data can be added to it. For this, Kärcher used a custom Python function built on top of the tool kit, leveraging the power and flexibility of the Python ecosystem.

Granta MI importer interface with progress information

Making Importing Data Easier and Error Free

This new process presented a notable improvement for Kärcher materials engineers, enabling them to automatically transfer data between the measuring device and the Granta MI platform effortlessly and without errors. “The new process is simple yet powerful and easily adaptable to most of our test equipment. Highly qualified materials engineers prefer to deal with their data rather than with data handling. And they can do that now,” Manocchio says.

Native integrations play a significant role in adopting new technologies and processes. Engineers often invest considerable time into learning new tools, and with each new tool comes the potential for new errors as users become familiar with them. Native integrations are designed to minimize the learning curve by enabling engineers to use new tools in conjunction with the tools they are already proficient in.

APIs, along with native integrations, can minimize errors by implementing programmatic logic that consistently reproduces a specific process with minimal user input. Additionally, when integrated with other software, these programmatic processes enable nonexpert users to directly engage with the technology and enhance their productivity. This leads to reduced frustration and risk when handling time-consuming, repetitive tasks.

With the Granta MI platform, engineering organizations can benefit from native integrations and comprehensive, well-documented APIs to make the most of their materials data while ensuring that it is reliably and accurately transferred across diverse engineering and enterprise systems.

Learn more about how the Granta MI platform can help you make the most of your materials data.

“The new process is simple yet powerful and easily adaptable to most of our test equipment.”

— Daniel Carmine Manocchio, manager, Kärcher Materials Laboratory

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.