-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

March 23, 2023

Students Compete in the Ansys Ibero-American Material Selection Challenge

The Ansys Ibero-American Material Selection Challenge is a yearly student competition in which students answer an engineering challenge of their choice and the selection of materials is the decisive factor.

The Material Selection Challenge is an opportunity for students to practically apply the knowledge they learned in material selection courses on an engineering topic close to their interests — such as sustainability, energy generation, or healthcare. The students propose innovative material uses and support their choices using Ansys Granta EduPack and the systematic material selection methodology developed by Professor Mike Ashby, of the University of Cambridge. Students could earn bonus points by demonstrating the soundness of their designs with Ansys simulation.

Originating in 2016 in collaboration with the Spanish Polytechnic University of Madrid (UPM), the challenge is open to all students of Spanish- and Portuguese-speaking universities. Each project, proposed by a single student or group of students, must be supervised by an educator in charge of tutoring the students throughout the challenge. The final ceremony takes place on-site at UPM, where groups defend their project in front of a jury of professors and Ansys experts.

The Course of the Challenge

The 2022 challenge started May 15 and was split into different stages: admission, submission, and selection of competing projects. It ended November 2, when the jury elected the three winners among nine finalist groups from Brazil, Colombia, Ecuador, Mexico, and Spain.

The most important criteria for the jury was the originality of the subject, the practical application of the solution in the industry, the degree of completeness, and the motivation, imagination, and ingenuity demonstrated by the students.

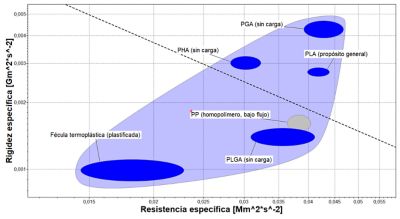

Competitors used an Ashby diagram, like the one above, in Ansys Granta Edupack during the challenge, which enables users to compare and choose materials.

And the Winners Are …

Third place went to Universidad Politecnica Salesiana (UPS) of Ecuador, with the project “Manufacturing of a Plastic Bottle Blow Mold for Small Series Production by Stereolithography 3D Printing.” This project addressed an existing challenge of the Ecuadorian mold industry, as small-series productions of customized plastic bottles are very costly due to the materials used for the molds, steel, and aluminum. Based on stereolithography 3D printing of photo-sensitive resins, UPS developed a less costly solution and tested it successfully with an industrial partner.

Second place went to UPM of Spain with the project “Manufacturing of Nets for Fruits and Vegetables Under the Principles of Eco-Design and Sustainability.” Using Ansys Granta tools and developing a rigorous methodology, they succeeded in finding an alternative to polyethylene and polypropylene, which are widely used and derived from petroleum hydrocarbons, but still complied with all the technical requirements.

The alternative material is biodegradable, compostable, and in compliance with food regulation. Its mechanical properties are in accordance with net shape to keep the food products fresh and airy. As manufacturing costs are also an important criterion, UPM’s team found an alternative material superior to the cost of current materials. The successful candidate was polylactic acid (PLA), a type of polyester made from the fermented plant starch of corn, cassava, maize, sugarcane, or sugar beet pulp.

First place went to Escuela Superior Politecnica del Litoral (ESPOL) of Ecuador for their project “Selection of a Material for Hydrokinetic Turbine Blades.” The city the university resides in, Guayaquil, often suffers from flooding and excess pressure in its water pipeline system. The project took advantage of weather events to harness the hydropower to produce energy. Hydrokinetic turbines are an interesting alternative, but require investment and a comprehensive design because current blades are expensive and difficult to process. Thanks to an inventive and rigorous methodology, using Granta EduPack, they selected the materials that fit all the requirements — both technical and cost.

Aware of the changes to come, today's engineering students are eager to design solutions for an ecological and societal transition. The equation of product development is becoming increasingly complicated to solve, considering new criteria such as ethical sourcing, environmental impacts, and recycling to consider.

The Ansys Ibero-American Material Selection Challenge is an opportunity to discover that materials science is a key discipline that empowers engineers to realize their new ideas for a better and more sustainable future.

This year, Ansys is hosting a materials selection challenge internationally! This educational event will gather students from multiple countries to showcase the most innovative uses of materials and simulation. Learn more about rules, prizes, and registration here.