Design for Metal Additive Manufacturing: Print Parameter Exploration

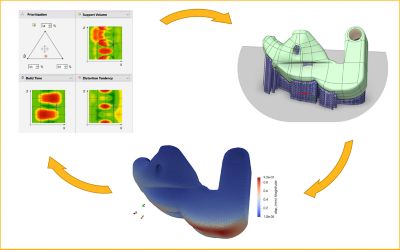

In this final segment of the three-part case study series of Design for Additive Manufacturing (DfAM), the stress and displacement occurring during the laser powder bed fusion (LPBF) process of manufacturing an airplane bracket is simulated, using the results of the previous two segments as input. The configuration of the simulation setup is explored, and the results show that this input causes significant residual thermal stresses and displacement. The case study series is then concluded by providing ideas on how these issues can be remedied by iterating the design process through changing processing parameters, supports structure and post-processing. The open-ended nature of this case study provides a perfect starting point for further exploration and try to come up with best practices in setting up DfAM. This case study utilizes Ansys Additive Print™, a standalone metal additive manufacturing solution.

Learning Outcomes

- Ability to use Ansys Additive Suite to simulate the print process to explore the AM-induced stresses and distortions

- Ability of identifying any potential issues that can lead to part failure

Applicable Courses for Use

- Additive manufacturing

- 3D printing

- Digital manufacturing

- Manufacturing process

Downloadable Content

- Case study report

- Simulation files