Design for Metal Additive Manufacturing: Materials and Process Optimization

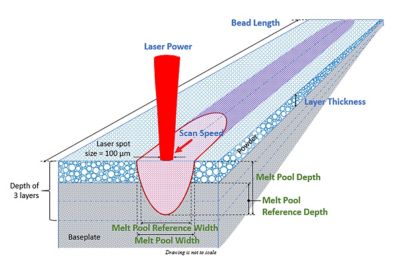

As one of the pillars of Industry 4.0, additive manufacturing (AM) is finding its place in engineering education curricula. The standard industry practice utilizes AM simulation to ensure that components are produced with minimal experimental trial and error. This case study is first in a series of three that explore this AM workflow in the context of producing an aeronautics bracket through Metal Additive Manufacturing (MAM). This workflow starts from material selection in Ansys Granta EduPack and progresses to optimizing the processing parameters used in MAM for this selected material to ensure minimal porosity using the tools available in the Ansys Additive Suite software are utilized.

Learning Outcomes

- Understanding metal additive manufacturing workflow

- Ability to use Ansys Granta EduPack for material selection

- Ability to use Ansys Additive Suite to optimize process parameters used in MAM

Applicable Courses for Use

Additive Manufacturing, 3D printing, digital manufacturing, manufacturing process

Related Resources

Design for Metal Additive Manufacturing Part 2: Topology Optimization and Build Preparation

Exploring AM Print Parameters | Ansys Education Resources

Downloadable Content

- Case study report

- Simulation files