WHITE PAPER

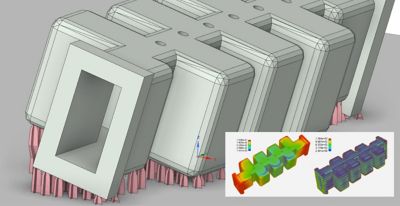

Additively Manufactured High-power, Lightweight Millimeter-Wave Band-pass Filter Optimized with AI Tuning Algorithm for 5G Space Applications

High-power, lightweight radio frequency (RF) passive components are critical for satellite communication payloads and are required to handle increasingly larger peak/average powers over the frequency range in the transmit path of the communication link. The powder-bed fusion metal additive manufacturing (AM) process has matured as a breakthrough technology for the development of arbitrary shape RF and microwave components, where conventional machining can be complex or impossible to use. When it comes to space applications, industries rely on testing to mitigate system failure. Reproducing space conditions for validation in laboratory settings is costly, time consuming, and ultimately unreliable. Hence, leveraging the use of artificial intelligence (AI) optimization techniques in the design process of RF components is impactful. The presented work demonstrates the use of physics-based simulation technologies from modeling/synthesizing to the manufacturing process of an optimized millimeter-wave band-pass filter that can be safely launched to space for satellite communication.

To learn more, submit your request to download the full white paper.