Case Study

-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

“When our simulations get to be a certain size, it is absolutely essential that we run on high-performance computing (HPC) clusters on the cloud to support a more digestible workflow. Ansys HPC applications on Microsoft Azure have been the best experience running an HPC service. We have access to a lot of Ansys tools, but we could not have, in any reasonable amount of time, gotten anywhere using them without this service.”

— Nathan Moshman, Founder, Moshman Research

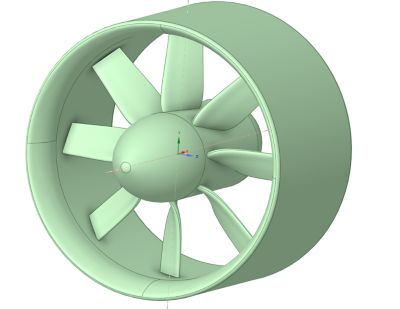

Moshman Research partner Avigation is developing a heavy-lift semi-autonomous unmanned aerial vehicle (UAV) for rapid wildfire response, the Hellbender Wildland Fire Response System. The system features a mountaintop-launched aerial platform design with a sheet spray misting system to enable rapid response and optimal suppression. Using simulation to optimize thrust efficiency of the fan blades, Moshman (in support of Avigation) hoped to maximize system operation time for better fire containment that leads to less destruction of forests, property damage, and loss of life.

Figure 1. Preliminary Results – CAD

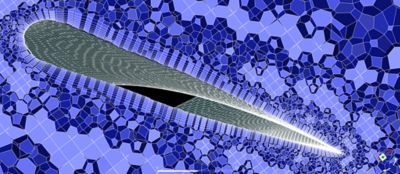

Figure 2. Preliminary Results – Mesh

Challenges

For Moshman, the challenge was to perform a proof-of-concept shape optimization of a ducted fan blade primarily using computational fluid dynamics (CFD) to demonstrate improved performance at a relevant operating point. It was a task involving a large model that included tens of millions of elements. Even with a simplification of the full geometry, modeling was still done in three dimensions, adding another layer of complexity. This resulted in hours-long runtimes on local machines punctuated with stops and starts during analysis, which was detrimental to maintaining workflow. Additionally, the team needed to consider adjoint solve time, deformation settings, and degrading mesh quality over design iterations during shape morphing to fully optimize the efficiency and performance related to fan blade tip shape and curvature.

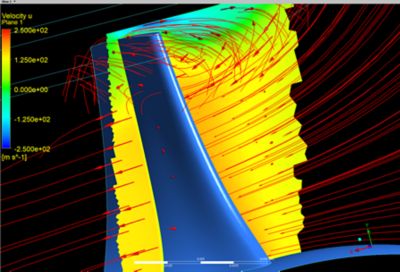

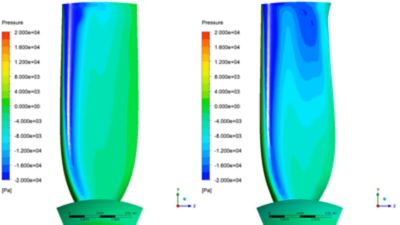

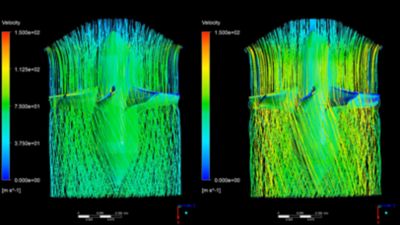

Figure 3. Preliminary Results – CFD

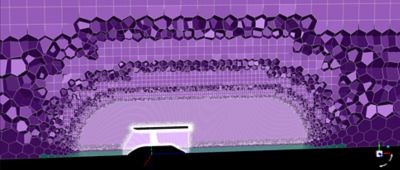

Figure 4. Final Mesh

Engineering Solution

Researchers benchmarked Ansys CFD on HBv3 virtual machines powered by AMD EPYC™ 7V73X (code name: Milan-X) processors, utilizing 96 cores on Microsoft Azure. Taking advantage of Ansys HPC applications on Microsoft Azure for production runs enabled the team to efficiently minimize necessary computational load on local, low-core count machines to support more complex CFD analysis.

- Moshman could then leverage various Ansys solvers to:

- Perform a proof-of-concept shape optimization of a ducted fan blade to demonstrate improved performance at a relevant operating point.

- Understand favorable blade shape and flow attributes.

- Examine trade-offs in efficiency, thrust, power demand and acoustic signature.

- Use a known starting point for verification.

- Perform mesh convergence studies.

- Generalize and automate computer-aided design (CAD) processes for rapid generation of more fan and blade shapes.

- Use two rounds of shape morphs to maximize thrust by morphing blade shape in the deformation box.

Figure 5. Second round of shape morphs

Benefits

With a quasi-fixed fan blade tip, the shape morph process yielded a 32.6% increase in thrust produced by the blade and led to increased efficiency overall. Freeing up the blade tip led to a shape producing a greater net thrust but no change to efficiency.

- Upon running a cluster with Ansys HPC applications on Microsoft Azure, a job that normally took hours was reduced to a few minutes on the cloud and supported a more streamlined, continuous workflow.

- Introducing these higher computational capabilities enabled complex CFD analysis of the Hellbender autonomous fire suppression system’s fan geometry in Ansys Fluent.

- This activity helped Moshman researchers better understand bending, deformation, and thrust forces of the individual blades, which led to extended fire suppression system operational times.

- Combining engineering and simulation on the cloud without interruption serves a critical need for Moshman in a research-driven environment, where losing momentum can be a major disruptor to innovation.

- With Ansys’ flexible licensing and cloud computing, engineers have near-instantaneous access to resources needed to learn very large models, plus starting or stopping a virtual machine in real time.

- End users can spin up a cluster in a matter of minutes and remove any hardware barriers, and easily scale up or down.

Figure 6. Illustration of the UAV Hellbender Wildland Fire Response System

Contact cloud-sales@ansys.com for further details on how to get started with Microsoft Azure.

If you want to get in touch with Moshman Research: moshmanresearch.com/contact

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。