Case Study

-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

“Our goal is always to propose and deliver high-quality, high-performance connectors to our customers in a timely manner. Ansys HFSS software has become an indispensable tool for improving the design quality and rapid release of high-speed transmission connectors.”

- Hiroyuki Taniguchi, Senior Supervisor, Hirose Electric Co., Ltd.

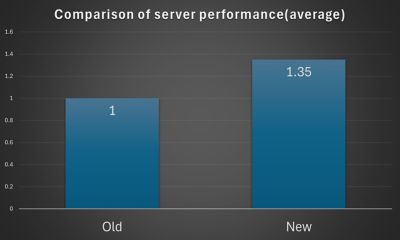

Artificial intelligence (AI), 5G, and the Internet of Things (IoT) are among some of the state-of-art technologies requiring advanced electronic equipment with sophisticated components. Hirose Electric creates one of the most advanced connectors for world-renowned companies. A crucial component of the connector design is Ansys HFSS high-frequency electromagnetic simulation software. The high-end electromagnetic simulation enables experts to explore and find the best design. With Dell PowerEdge equipped with AMD EPYC processors, the simulation time decreases by 30% to 50%, and the user can achieve results faster than ever.

Challenges

Since 2008, Hirose Electric has leveraged HFSS software for electromagnetic analysis. After a decade of relying on the same server infrastructure, it became evident that their existing system could no longer keep pace with the increasing demands of advanced simulations. Processing times for high-speed connector simulations had stretched to several hours or even days, significantly impacting development efficiency. Additionally, their dependence on HDD storage led to I/O bottlenecks, further slowing simulation performance. Managing eight separate machines also imposed a heavy maintenance burden, requiring substantial resources for updates and system management. To sustain their competitive edge, it became clear that a major hardware upgrade was essential.

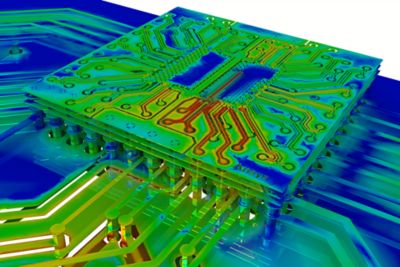

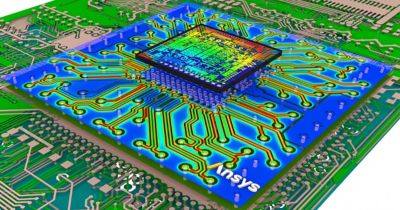

Ansys HFSS integrated circuit (IC) modeling

HFSS software enables breakthrough innovations in IC design, including 3D-IC interposer stack electromagnetic (EM) analysis

Engineering Solutions

After extensive evaluations using HFSS software, Hirose Electric chose servers powered by AMD EPYC processors and Dell PowerEdge hardware, a decision driven by several key factors. The AMD EPYC processors provided a higher clock frequency and greater core counts, enabling faster, more parallelized simulations that significantly boosted performance. The combination of high computing power and competitive pricing also delivered an exceptional cost-to-performance ratio, making it a financially sound investment. Reliability was another crucial consideration, with Dell PowerEdge servers offering a proven track record of stability and minimal downtime. By consolidating their simulation infrastructure from eight separate machines to just two high-performance servers, Hirose Electric streamlined maintenance efforts while dramatically increasing processing capacity, ensuring their engineering teams could work more efficiently than ever before.

Benefits

The impact of the hardware upgrade was both immediate and substantial. Simulation processing times saw a dramatic reduction of 30-50%, allowing for faster iterations and more efficient decision-making. With each server now offering four times the core capacity, Hirose Electric was able to sustain peak simulation performance while significantly reducing the number of machines required. This upgrade also transformed the workflow within the company — where designers had once hesitated to request simulations due to long processing times, they now actively leveraged the enhanced infrastructure to accelerate development and innovation.

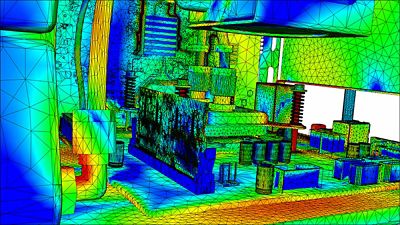

HFSS mesh fusion enhances simulation accuracy for complex cabinet designs

A performance comparison of old and new servers

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。