Case Study

-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

“Using Ansys solutions allowed us to iterate our humanoid robot’s design with confidence. The ability to simulate mechanical stresses, actuator loads, and kinematic behavior before building helped us catch design flaws early. It accelerated our progress, saved material costs, and made us stronger engineers.”

-Abhinav Swarup, President, Triton Droids

At Triton Droids, a student team from the University of California, San Diego, students set out to build a life-size humanoid robot capable of complex motion and stability. Humanoid robots represent the future of robotics, and building one gives students invaluable hands-on experience in an emerging field that bridges mechanical design, control systems, and artificial intelligence (AI).

To meet strict mechanical and power constraints, the team turned to engineering simulation. Ansys software enabled the team to validate and optimize structural integrity and actuator dynamics before physical prototyping, saving valuable time and resources.

Challenges

Designing a humanoid robot involves complex mechanical linkages and multiple degrees of freedom. Balancing weight, strength, and agility while ensuring efficient motor and joint operation proved to be a significant challenge. Calculating joint torques in the leg was difficult, as each joint’s required torque depends on both the motor specifications and the weight of components further down the chain. As a result, simulation became essential for accurately predicting performance under load, reducing overall weight, and minimizing the risk of mechanical failure.

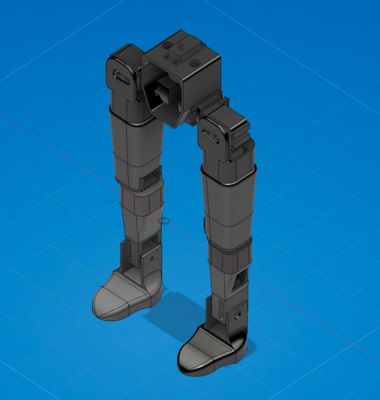

Computed-aided engineering (CAD) model of Triton Droids’ five degrees of freedom (DOF) humanoid leg with modular joints for the hip, knee, and ankle

Engineering Solutions

- Ansys Mechanical software helped the team simulate the load on the robot’s joints and frame to ensure structural integrity.

- Ansys Motion software helped optimize actuator and linkage dynamics, especially for walking and balance.

- With Ansys solutions, the team was able to analyze material stress and deformation during dynamic actions like standing, walking, and object manipulation.

Baxter industrial robot donated by the team’s advisor, which was used for manipulation and perception research

Benefits

Using Ansys software drastically reduced trial-and-error cycles. Students identified and corrected weak points before manufacturing, which saved time and reduced costs. It also accelerated learning: by comparing simulation data with real-world testing, the team gained a deeper understanding of force transmission, balance, and system dynamics in robotics.

Demonstration of the leg prototype featuring three DOF at the hip, one DOF at the knee, and one DOF at the ankle

Joint layout of the humanoid leg with degrees of freedom depicted

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。