-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

Discover how Ansys Granta MI software can help streamline CAD-to-CAE workflows to fuel precision and quality in automotive design.

Materially speaking, steel is a mainstay in automotive manufacturing. Yet simply reducing vehicle design to a “hunk of metal” barely scratches its surface. In fact, automakers use more raw materials than just about any other industry. An average vehicle build employs approximately 50 different materials.

Of these, plastic, aluminum, rubber, glass, and various composites are all foundationally significant. Variations of each are routinely used across an entire vehicle platform, further defined by strength, weight, and cost, created in consideration of numerous physical and material properties.

With so many material considerations, how do automotive manufacturers identify the best for a given program? Armed with the right data, this dilemma of choice can work in their favor. Access to on-demand material models in CAD and simulation environments helps to ensure precise, consistent data generation. In turn, efficient workflows powered by this data lead to better material designs.

Further, the use of comprehensive material models can eliminate risks associated with fragmented or siloed data coming from various sources. Material data is captured in its entirety, enabling engineers to maintain accuracy throughout projects.

The integration of robust tools like the Ansys Granta MI materials intelligence platform as part of the streamlined CAD-to-CAE workflow provides engineers with seamless access to critical material properties. It’s good foundational knowledge that ultimately informs both precision and quality in automotive design to improve decision-making and reduce simulation errors in an existing product development environment.

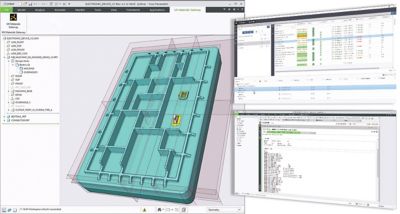

Materials information assigned through the Ansys Granta MI platform on a part designed in PTC Creo and managed by PTC Windchill PLM

Material Intelligence Has Its Engineering Advantages

During product development, engineers must consider all materials in play from numerous perspectives. There’s the materials themselves, of course, including what data is available on them and what type of application they are being used for, as well as what can be physically built and tested with them in line with regulations and requirements.

Today’s vehicle systems involve a complex mix of materials, including metals, polymers, and composites, with distinct properties and manufacturing processes. Considerations for their use further expand to multidisciplinary areas, such as electromagnetics, acoustics, and optics. Then there’s the actual definition of the material itself in terms of basic composition, as well as other properties to help frame its use.

All these concerns can quickly become unwieldly as products move from the initial design phase to testing and development and then on to production. All the while, the cost of materials is increasing, requiring thoughtful choices on how and where they should be applied, as well as possible alternatives — which are often difficult to find. Naturally, the more data or material intelligence that engineers have upfront, the easier it will be to sort through these and other material challenges during development.

“The advantage of material intelligence is powerful,” says Austin Flanary, manager, application engineer at Ansys, part of Synopsys. “When you centralize this data, make those different perspectives of materials available to you to look at, empower, and allow your engineering team, your test team, your manufacturing engineers, your sustainability officers, and even your procurement team to work together and look at the same thing, you increase the efficiency of communication by a significant order of magnitude and even push things further to a point where now you've got time to do some cool stuff.”

On-demand material models for use in CAD and simulation environments are a critical component of material data centralization that leads to better design decisions down the line. Intelligence platforms like Granta MI software are well positioned to play a central role in data gathering.

One Model To Keep Empirical Knowledge Flowing

In automotive engineering, combining forces often yields better results. This is certainly true when CAD tools, product life cycle management (PLM) solutions, simulation tools, and material intelligence software are incorporated into one streamlined development workflow. Real-time communication among all facilitates automatic updates to material properties and configurations across platforms, empowering engineers with real-time results.

Granta MI software facilitates smooth data flow between design and simulation environments to enable critical tasks. These include the direct transfer of material properties into CAD or simulation environments, a task that might otherwise require manual data entry. Free-flowing data transfer among tools reduces the risk of human error while speeding productivity for large assemblies with complex material requirements.

“This is a feature that should be ubiquitous, but a material model is an important component to think about because it's a building block for the actual integrated solutions at a larger scale,” says Flanary. “Then it’s about connecting your engineering tools, what it looks like when you use a solution from Ansys to actually connect to one of the common CAD simulation or PLM tools that exist.”

No Time To Waste With Seamless Assignment Transfers

Material assignment transfer in automotive design, or the matching of materials to the components in a given vehicle design, is decidedly complex and time-consuming. It can be an incredibly tedious activity for engineers managing large assemblies involving hundreds of components.

Automation reduces this effort and eliminates manual input. This gives engineers the ability to maintain consistency when working across systems without duplicating efforts. Switching among CAD, PLM, and simulation environments, automated tools can read a product’s bill of materials (BOM), then assign the correct material properties directly to the corresponding parts automatically between design and analysis workflows.

Further, additional material properties for advanced simulations can be included without inflating CAD file sizes, which can slow performance, cause file transfer problems, and create data management and storage issues. Whether dealing with structural components, thermal analysis, or electromagnetic properties, the automated transfer of material assignments prevents delays, including those caused by manual mismatches.

Transferring material properties from PTC Creo to Ansys Workbench via the Ansys Granta MI platform, keeping all the materials information and assigning it easily for simulation use

Future-Proofing with Automation and Optimization

The representation of a material model in the context of a workflow is a crucial step to ensuring the continual flow of material data among tools. Once engineers have identified tool sets and established a workflow for data transfer, automation and optimization tools can be used to further streamline and enhance the precision of engineering and manufacturing processes.

Of course, while the workflow itself offers inherent benefits, the addition of automation and optimization technologies maximize them through the execution of repetitive tasks quickly. This frees up valuable focus time better relegated to solving critical design challenges and exploring future innovations.

As materials data continues to grow exponentially in volume and complexity, these tools are central to managing and analyzing the information needed to tackle emerging challenges.

Specifically, automation and optimization tools can:

- Enable the identification of optimal material configurations in consideration of performance, cost, and sustainability metrics through the application of advanced algorithms.

- Help clarify complex tradeoffs, such as the balance of lightweight designs with durability, or the impact of thermal performance under certain constraints during manufacturing.

- Introduce a level of scalability and resilience during development and manufacturing that enables engineering teams to quickly pivot to respond to changing market demands or regulatory requirements.

- Enhance collaboration among departments through real-time access to optimized data sets, ensuring decisions made during development align seamlessly with manufacturing, procurement, and compliance processes.

Here are a few examples of how putting automation and optimization in action benefits automotive customers.

Honda Motors and Lamborghini Cut Material Costs With Ansys

It turns out that a little material savviness, with help from Ansys, part of Synopsys, can really pay off.

Granta MI software played a pivotal role in enhancing design efficiency for Honda Motors by helping generate material models on demand faster while simultaneously speeding decision-making and reducing expenditures in the process.

Specifically, it was Granta MI software’s ability to automatically link records and overlay graphs across multiple datasets that helped simplify material data management.

"Because of its huge comparative advantage, including extra functions to automatically create a link between records and overlap graphs contained in multiple records, we chose Granta MI," said Honda Motors’ Assistant Chief Engineer Tsuyoshi Ito, in a case study.

This approach also enabled a 50% reduction in prototype materials and tests, cutting down development time and costs while improving overall efficiency. And Granta MI software helped Honda Motors realize a 41% reduction in material property acquisition costs for simulation models.

Automotive customer Lamborghini also benefited from Granta MI software’s automation features to streamline development and achieve up to 20% reductions in material testing costs and time, driven by enhanced tool and procedure automation.

These results reflect how a centralized, automated material data system driven by Ansys can foster innovation while ensuring compliance and precision during vehicle development.

Practical Solutions for Connecting Material Data Across Engineering Systems

Integrating material data into nonstandard systems for carmakers can be challenging. Granta MI software delivers the flexibility needed to accommodate unique workflows and environments, ensuring that material data can be shared across platforms. Check out Practical Solutions for Connecting Materials Data Across Engineering Systems for more on how to streamline CAD-to-CAE workflows, improve decision-making, and reduce simulation errors in your existing product development environment.

Just for you. We have some additional resources you may enjoy.

"Because of its huge comparative advantage, including extra functions to automatically create a link between records and overlap graphs contained in multiple records, we chose Granta MI."

— Tsuyoshi Ito, Honda Motors’ Assistant Chief Engineer

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.