-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

ANSYS BLOG

December 9, 2021

Optimized Processes Drive an Optimal Return

If you’re reading this blog post then obviously you, and your organization, are significantly invested in engineering simulation. But are you maximizing your return on that investment? How well are you managing the everyday processes involved in applying simulation software to model, study, and improve product performance?

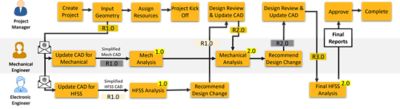

Your engineering staff is probably using Ansys solutions to accomplish amazing, complex, and sophisticated analyses of your products’ performance. They’re applying multiple physics. They’re working at the component and system levels. They’re leveraging every feature of Ansys software to verify that your innovative products will work, as promised, under thousands of operating parameters and a wide range of real-world environmental conditions.

But here’s what your engineers aren’t telling you: overall simulation process management in your organization is probably less than amazing. And it’s not your engineers’ fault. It’s because they lack an equally sophisticated, customized solution to manage the myriad steps in between individual simulations ― the data transfers, the process handoffs, the alerts and reports, the job assignments, the aggregation of results, and other simulation tasks.

They’re managing all these process steps via unsophisticated and untraceable methods like emails, voice mails, verbal conversations, and physical handoffs of a jump drive. They might be using a consumer-grade tool like Excel or a purpose-built solution like Jira ― that’s, unfortunately, built for another purpose entirely. These tools aren’t linked directly to Ansys software or to simulation data. There’s no formal workflow, no shared platform and no way to track project status in real time.

As a result, your engineers are making a range of mistakes, like importing the wrong data, using an outdated file version, or re-running a simulation. There’s no real accountability, so it’s hard to keep track of where projects are in the pipeline. No one is sure what the next step is, and who owns it. No one is even sure if the last step was completed successfully. Older projects lag. And new projects proceed slowly, because past simulation results are pushed aside and forgotten, instead of being re-used when a similar project is kicked off — resulting in redundant effort and lost time.

Whether you realize it or not, all this inefficiency is slowing down your product development results and interfering with your ability to derive maximum value from your simulation investments. You’ve chosen to use a carefully optimized engineering simulation solution. You’ve attracted the best and brightest product development talent. So why are you supporting your Ansys software, and your engineering team, with suboptimal simulation management processes?

Gain Speed, Precision, and Control with Ansys Minerva

The good news? It’s easier than you think to optimize your simulation management processes and maximize your return on investment.

Ansys has applied its decades of industry leadership, and its deep knowledge of engineering best practices, to develop Ansys Minerva ― an enterprise-level simulation process and data management (SPDM) solution that matches the power and sophistication of Ansys’ physics-based tools. Ansys Minerva is an advanced, specialized platform that manages the incredible complexity of everyday simulation process management.

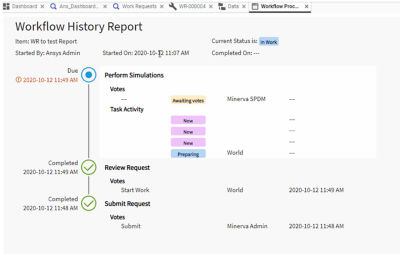

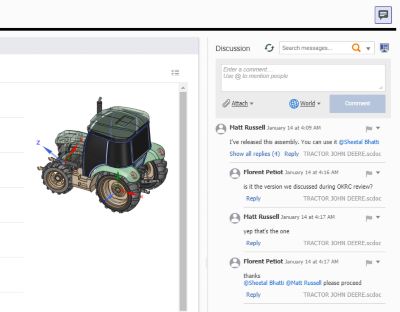

With Minerva, all the information your engineers need to drive projects forward, maximize productivity, and accelerate product launches is right at their fingertips. Task trees, role-specific views, and automatic notifications of project updates provide all users with real-time visibility, traceability, and accountability. Guesswork, errors, and tedious manual handoffs are replaced with speed and automation, to support the fast, optimal execution of your critical simulation-driven product development processes.

Because all data and process information is centralized, the knowledge gained during previous simulations can easily be applied to new projects, whether in the form of simulation data, templates, or best practices. Because your team members are never starting from scratch, their efficiency, and productivity are maximized.

Best of all, Minerva delivers all this robust functionality in an intuitive, easy-to-use package that resembles consumer software. While Minerva is working hard behind the scenes to manage your most critical simulation data and workflows, even non experts can interact with the solution easily and effortlessly.

Minerva’s vendor-neutral architecture enables you to seamlessly connect powerful simulation and optimization solutions from Ansys to your existing ecosystem of tools and processes. And, because Minerva can be deployed on-premise or in the cloud, it connects your team members regardless of physical distance or functional silos.

Make Fact-Based Decisions That Maximize Outcomes

Every day, engineering simulation fuels critical business decisions that have the power to determine your products’ success or failure in the marketplace. Shouldn’t these decisions be made in an optimized environment, characterized by visibility, traceability, and access to accurate, real-time data?

Beyond maximizing the value of your human and technology assets, and shortening the product development cycle, Minerva adds real financial value by providing a fact-based context for your foundational product decisions. Think about the strategically important work your engineering team is doing every day and ask yourself: am I doing everything I can to amplify and accelerate their efforts? If you’re ready to take your engineering results and financial returns to the next level, request a demo of Ansys Minerva today.