-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

ANSYS BLOG

April 20, 2021

More Fast Processor Options for Engineering Simulation

To meet their deadlines, engineers need faster processors so that they can run larger, more complex simulations and explore more design (or parametric) variations. Now that AMD and Ansys are collaborating to ensure the new 3rd generation AMD EPYC™ processors will slash Ansys structural and fluid dynamics simulation run times, engineers have a broader choice in high-performance computing (HPC) resources.

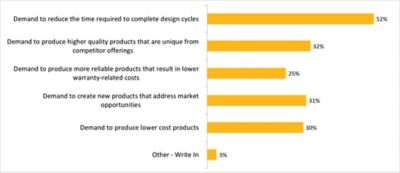

In our 2020 HPC usage survey, engineers told us they are still facing increasing pressure to produce better designs faster. According to survey respondents, the top design challenge is the demand to reduce the time required to complete design cycles.

Top engineering design challenges, according to respondents to our 2020 HPC Usage Survey

We also know that many simulations require significant time to run. Slightly more than a fifth of respondents (21%) reported that their most frequent simulations are overnight runs that take more than 9 hours to complete. To support these simulations, engineers need to run more simulations on HPC servers or clusters that increasingly rely on better performing processors and parallel processing capabilities.

Processor Competition Heats Up, Engineers Benefit

Despite the increasing complexity of simulation workloads, faster processing, increasing memory bandwidth and lower latency have enabled shorter time to solution with simulation. These gains have primarily been made via x86 systems based on Intel® CPUs. However, in recent years, competition in the market — mainly from AMD — has provided additional options for engineers. According to our survey, 69% of respondents run their simulations on Intel® Xeon® processors (and 3% are running on other Intel processors), while 13% use AMD processors. Another 14% did not know which processors they are using. Although the majority of HPC resources still use Intel processors, AMD has already demonstrated relatively good performance in its 2nd generation of EPYC “Rome” processors in comparison with specific Intel Xeon processors.

High Memory Bandwidth, Large Caches and High Frequencies Equal Faster Simulation

Last month, AMD launched “Milan,” the 3rd generation of EPYC silicon, which features high frequency, high memory bandwidth and capacity as well as extra-large caches. Improved memory bandwidth and latency of these processors are enabled by 8 memory channels of DDR4-3200 RAM, up to 4TB of memory per socket and up to 256MB of L3 cache per CPU (up to 32MB per core). These specs are particularly useful for high-value applications that require a lot of memory, such as computational fluid dynamics (CFD), explicit Ansys LS-DYNA simulations and iterative Ansys Mechanical models.

AMD’s new EPYC 75F3 processors speed up Ansys simulations, such as crashworthiness simulations performed by Ansys LS-DYNA.

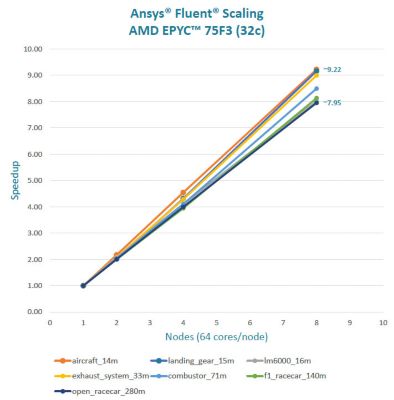

Multi-node scaling performance of AMD EPYC 75F3 based systems up to 8 compute nodes running the largest seven benchmarks in the Ansys Fluent suite. At 8 nodes, the expectation for predictable scaling would be a speedup of 8; however, the data shows scaling efficiency of 9.22. This indicates that each system is doing more work in the same amount of time when working as part of a cluster run than it did when running standalone. This super-linear scaling is caused by “cache effect.” Fluent can very efficiently use the extra-large caches available on EPYC 7003 Series processors.

For example, some of the more complex fluid flow or crash simulations can consume a lot of memory. Having more memory capacity allows data to be fed into the CPU much quicker via 8 memory channels, which will have a big impact on performance. With high frequencies and impressive instructions per cycle (IPC) rates, AMD’s 7003 Series of processors has become an even more compelling option.

Intel is not sitting still either. Earlier this month, they launched the new Intel Xeon “Ice Lake” processors. Ansys and Intel have worked together to help our customers run larger, higher-fidelity models on this 3rd generation Intel Xeon Scalable Processor family. Thanks to Intel AVX-512 and 8 channels of DDR4-3200, a 1.48x higher performance can be achieved across a wide variety of Ansys Fluent, Mechanical and LS-DYNA simulation workloads versus prior generation of Intel processors. It helps to make HPC even more strategic for design and engineering teams.

Many Ansys applications like Ansys HFSS and sparse direct solver applications in Mechanical take advantage of Intel AVX-512 support and therefore run faster on Intel processors on a core-by-core comparison basis.

Choose the Best HPC Configuration

Having a choice of processors is great for innovation, but it also means you now have to consider more options when determining what HPC configuration is best for your particular application. At Ansys, we also work with HPC partners like HPE, who can help guide you to the best HPC server configuration for your Ansys applications.

For example, Ansys and HPE have defined some cluster configurations that are optimized for Ansys simulation workloads:

- Ansys Reference Configurations for Apollo 2000 Gen10 AMD Plus Cluster

- Ansys Reference Configurations for Apollo 2000 Gen10 Intel Cluster

And, if you want to know the speed-up improvements of a small HPC cluster running your own simulation models, then join the Free Performance Benchmark Program. For those who want to maximize flexibility when running various Ansys applications, Ansys Cloud offers on-demand computing resources optimized for Ansys simulation applications running within a secure cloud environment. With an Ansys Cloud trial, you can experience running Ansys simulations in the cloud at no cost. Learn more here.