-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

ANSYS BLOG

April 15, 2021

Data Management Powers Simulation Productivity

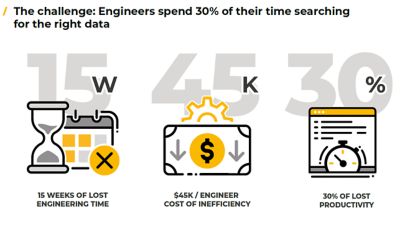

Where’s the data? That’s what engineers ask as they spend up to half of their time searching for project-related information, which translates to a whopping 15 weeks of lost productivity per year per engineer1.

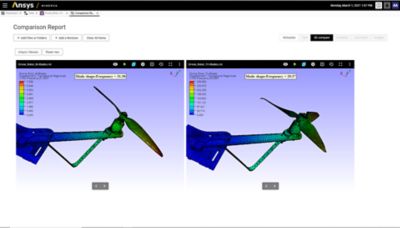

Engineers and their supervisors need a centralized location to manage simulation data, organize simulation workflows and simplify data sharing.

Just sharing the files isn’t enough. To maximize productivity, team members need background info with supporting context that explains how and why a simulation was generated and what was learned from it.

Without a simulation process and data management (SPDM) solution like Ansys Minerva, powered by Aras, engineers must organize and manage their files using a folder structure in their local machines or at best in their shared network drives, which proves cumbersome. Add email and office files to the mix, and the risk of costly miscommunication skyrockets.

Ansys customers are using SPDM to conquer simulation data management issues, access state-of-the-art simulation software and more effectively leverage high-performance computing (HPC). SPDM ensures that engineering teams are highly productive, organized and synchronized. This has proven to be especially important since most teams became distributed in the wake of COVID-19.

Source: Tech Clarity

Gearing Up to Work from Home

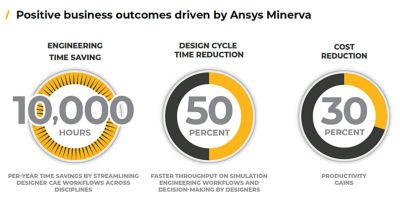

Minerva has changed the work-from-home landscape for engineers by making data available via a central interface, accessible via a browser, enabling engineers to connect from anywhere. And the same applies to compute resources, where Minerva streamlines access to HPC to expedite simulation analysis. In fact, engineers can expect significant time savings as they use Minerva to streamline computer-aided engineering workflows across disciplines.

Prior to the pandemic, many engineering teams would communicate and collaborate on projects on premise. But even then, there wasn’t oversight of the simulation process. Data resided on “islands,” preventing managers from understanding which work was being done, who was getting it done and when it was supposed to be done.

Today, as many engineers continue to work from home, visibility is needed to understand the status of their projects, what the dependencies are and where the bottlenecks might be. By using Minerva, engineering teams can realize substantial design cycle time reduction, enabling 30% faster1 throughput on simulation engineering workflows and decision-making by designers.

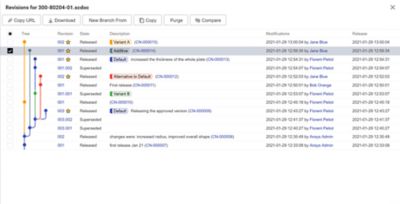

Today’s distributed teams must communicate and synchronize activities to ensure version control and understand which tasks must be accomplished. For example, if three team members used Minerva and worked sequential eight-hour shifts, they could collectively and seamlessly work nonstop 24/7 on a design project, completing the job 3x as fast – ensuring that engineering communities are using the right data, at the right location, at the right time to radically reduce development costs.

Revisions Tree

Engineers never know what kind of design challenge they’ll need to react to tomorrow. Minerva incorporates both Ansys and third-party solutions, enabling engineers to use a range of products to rapidly complete any task.

Minerva Helps Power Up Eaton

Eaton, a multinational power management company, recognizes the importance of simulation for improving product development

“Ansys Minerva is important to Eaton and plays a key part in our larger, enterprise-wide digital prototyping and additive manufacturing initiatives,” said Todd Earls, vice president of Information Technology at Eaton. “Ansys Minerva will help make our user experience more streamlined than it is today.”

Want a deeper dive into Minerva? Read more about it here.