-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

ANSYS BLOG

April 1, 2022

Charge Up EV Development with Battery Digital Twins

With fuel prices skyrocketing, many consumers worldwide are more than ready to embrace electric vehicles (EVs). Government officials and regulatory groups are also pushing for the widespread adoption of EVs, with U.S. President Joe Biden recently defining a set of ambitious goals1 — including a mandate that half of all cars sold in America will be electrically powered by 2030.

The world’s automakers are investing heavily in EV product development programs to capture this opportunity. With sales of EVs projected to reach $823.75 billion by 20302 — reflecting an annual growth rate of 18.2% compared to 2021 sales — automotive engineering teams are focused on making their offerings safe, affordable, and efficient, which are three key product attributes.

At the center of this engineering challenge is the EV battery pack. While high-capacity lithium-ion batteries — a viable option for powering EVs, have dropped significantly in cost3 since they were introduced — they still face challenges. Their heavy weight reduces efficiency, their range per charge is still relatively small, and much is still unknown about their performance degradation over time.

To develop a viable commercial EV battery design that can be counted on to deliver years of reliable performance, product development teams need to understand the long-term effects of temperature, climate and weather exposure, usage patterns, driving speeds, high and low charge states, and electric current variations on their battery designs.

The problem is that EVs are relatively new, so not much real-world data has been gathered with respect to battery performance. Physical prototypes and road tests are prohibitively expensive and time consuming, especially given the urgent nature of this engineering challenge. As with so many other complex, pressing product design problems, the answer lies in engineering simulation.

Twin Builder: Driving Rapid Battery Verification

For years, Ansys has offered end-to-end simulation capabilities for battery design, which have enabled engineers to study and manage thermal issues, create battery management systems, and overcome other challenges. Today, Ansys Twin Builder is a unique simulation solution that fully replicates the performance of EV batteries under real-world conditions over time.

How exactly does Ansys Twin Builder work? A digital twin is a virtual replica of a working product, such as an EV battery system, that allows engineers to apply real-world operating parameters and study their impacts. Using sensors mounted on an actual battery, engineers feed real-time performance data into a simulated model of that battery. To save time and computing effort, Twin Builder relies on proprietary reduced-order modeling (ROM) capabilities that focus on key performance aspects. ROM shortens run times from hours to seconds by simplifying computational complexity, while still delivering extremely rigorous engineering analysis.

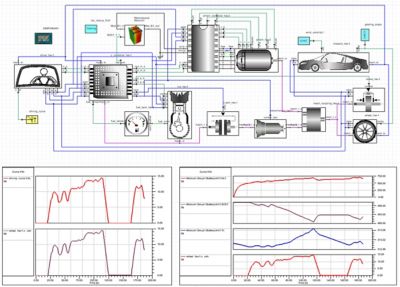

Shown here is a drive-cycle simulation that uses a system model of an EV composed of reduced-order models (ROMs) and components from the Ansys Twin Builder library.

While it’s impossible to see inside a working lithium-ion battery, Twin Builder reveals what’s happening as the design is subjected to various thermal, chemical, mechanical, electrical, and other effects. Development team members can visualize fluid flows, structural stresses, materials degradation, and temperature changes. After engineers have detected performance deviations and failure modes, they can correct them with new physical design features such as cooling systems and improved control algorithms. Thus, the development cycle is significantly accelerated without the need to build physical prototypes or remove working products from service.

Via transient studies and predictive analytics, engineers can use Twin Builder to look at long-term EV battery performance under a range of conditions. They can answer questions like: How do different temperature-control strategies affect the range of the vehicle? How many times can the vehicle be started without overheating the battery pack? Can the battery operate safely if the EV is involved in a crash? The product development team can run a variety of what-if studies on the digital twin without subjecting the actual working product to every possible operating condition.

Not only can engineering teams leverage Twin Builder to identify and prevent failure modes, but they can also customize battery designs to certain geographic regions based on their terrain, local driving behaviors, and atmospheric conditions. For example, batteries might age very differently in the cold temperatures of Norway versus the hot temperatures of Saudi Arabia, so these kinds of critical variations in operating conditions can be reflected in new regional product offerings.

Twin Builder also allows EV manufacturers to anticipate repair and maintenance needs upfront when introducing new battery designs, avoiding consumer complaints and setting the stage for long-term satisfaction and loyalty.

To help make battery analysis even faster, Ansys has created a feature in Twin Builder called Battery Wizard that simplifies the process of problem set-up via a step-by-step process. Engineers can quickly specify cell configurations, cell parameters, and variables such as battery charge state and temperature. This feature, combined with Twin Builder’s user-friendly interface and open, vendor-agnostic platform, enable EV development teams to quickly get their digital twins up and running.

Twin Builder features a Battery Wizard that walks development teams through a fast, step-by-step battery configuration process that greatly simplifies problem setup.

Lead the Field in EV Battery Innovation

With growing market pressures — and an incredible revenue opportunity — there’s no question that revolutionary new EV battery designs are coming. The only real question is, who will be the first to verify and launch them? Ansys Twin Builder is purpose-built to give your product development team a significant competitive edge.

Industry leaders are already deploying Twin Builder to gain an advantage. A123, a battery manufacturer, recently used Ansys Twin Builder to model a 48-volt, liquid-cooled battery pack.

With the help of the simulations, A123 can determine thermal dependency on electric performance, design cooling supply, calculate temperature distributions, and predict battery life, according to A123 Systems. A123 also utilizes Ansys Twin Builder's ROM technologies for simplifying complex 3D thermal simulation, which significantly reduces the simulation time from days to few seconds while keeping the required simulation accuracy.

Given Ansys’ historic leadership in physics-based simulation, no software provider is more qualified to help you launch a digital twin initiative and take a leading position in the race to launch EV battery innovations. Ansys Twin Builder can also help your team avoid costly battery failures and product recalls, optimize maintenance and repair, and reduce product development time and costs. Why not begin charging up your EV battery development efforts today by leveraging the power of Ansys Twin Builder?

Learn More

Offered in a convenient on-demand format, the Ansys Digital Twin webinar series covers a variety of topics related to digital twins. Learn more about how digital twin can be used to quickly build accurate system models by viewing “Battery and Fuel Cells System Modeling Using Ansys Twin Builder.” You can also discover the benefits of Ansys Twin Builder firsthand by requesting a free trial of Ansys Twin Builder.