-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

ANSYS BLOG

September 2, 2022

Making Faster Connections: How Ansys is Helping HARMAN Accelerate Connected Car Technology Performance

The proliferation of portable digital technologies has quickly transformed our lives. If you want to check your email, know how many steps you’ve walked, or identify the closest Starbucks, you can use your laptop, Apple Watch, iPad, or smartphone to find out. At the same time, the advent of 5G and autonomous driving is accelerating expectations for ultra-high speed, low-latency performance, and multiple connections wherever we are — including in our vehicles.

Drivers, plus everyone they choose to bring along for the ride, are looking for a seamless transition from home to their vehicles and destinations without compromising their digital lifestyles. With help from Ansys, HARMAN, a global leader and innovator in connected car technology, is delivering the hardware and software services needed to enable this experience.

State-of-the art digital cockpit domain controller, containing one system on a chip (SoC) driving five displays while offering high-class audio and latest generation connectivity.

“Fun in the car has moved from the actual driving experience behind the wheel to continuing your lifestyle experience with all the preferences you have in your car,” says Frank Gitzinger, director of product development, Digital Cockpit, at HARMAN. “Ideally, streaming your favorite songs at home, then jumping into the car, your playlist seamlessly continues through your USB, Apple CarPlay, or a similar connected app. And when you arrive to your destination, you should be able to continue listening on your phone. This experience will be as convenient as possible, enabled by our 5G technologies to ensure you’re always connected to the internet and the cloud.”

Standing at the Intersection of Performance and Power Consumption

As fast as our digital environment has been changing, achieving this level of performance sounds simple enough. But most in-vehicle infotainment systems still have limited functionality due to infrequent hardware updates and computing capabilities, as well as a lack of apps and services to support them. The shift to electrification and autonomous driving puts added demands on original equipment manufacturers (OEMs) to balance power consumption with vehicle performance, requiring faster rates of data transfer, high-speed digital interfaces, and next-gen memory. This is where DDR5, a synchronous, dynamic random-access memory that uses less power and allows higher data rates, comes into play. DDR5 elevates the performance and efficiency of next-gen mobile and other automotive apps to dramatically improve 5G, artificial intelligence (AI), and camera and display technology.

Implementing DDR5 into HARMAN’s cockpit environment is a complex task, so it’s difficult to have confidence in the layout without signal integrity (SI) simulations, largely due to the high-speed transfer rate and the complexity of the SI constraints involved. Extremely high data rates coupled with a poorly designed circuit board result in undesired interference, which can lead to a complete interruption in data transfer and ultimately to failure. To avoid this scenario, Gitzinger and team used Ansys HFSS simulation software to simulate every aspect of their controller design, from the main processor, also known as system on a chip (SoC), to memory. Drawing on performance data, they could validate designs with simulation and fulfill the requirements of the JEDEC, a global standards body for electronics, and other regulatory bodies simultaneously.

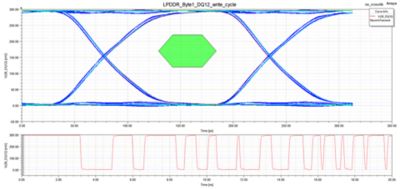

The eye diagram is an indicator of signal quality, simulating the signal integrity. The results are compared against the eye mask defined by JEDEC, the eye diagram helps to predict performance and identify possible source of issues problems like crosstalk, jitter, and impedance matching. To correct potential issues before PCB build does save development lead-time and money.

“Every generation of SoC we integrate in our products offers higher performance at about the same level of power consumption of the cockpit controller,” says Gitzinger. “We're getting more speed and more data without compromising vehicle range. Ansys tools like Ansys HFSS enable us to consistently stretch our performance goals through the optimization of our designs and help eliminate time-consuming design re-spins in the process.”

The goal of many OEMs in the automotive space is to transform the instrument panel into a display offering critical safety and infotainment information. HARMAN is using an electronic control unit (ECU), also known as the cockpit controller, to do this. Gitzinger’s team recently used Ansys simulation to enable this exact technology in high-end infotainment systems offered by renowned German, North American and Chinese carmakers. The digital design incorporates a very powerful cockpit domain controller driving all displays, which are seamlessly integrated into the dashboard, and also enables projection of smartphone applications.

Solving High-Speed Signal Measurement Challenges with Ansys HFSS

High-speed signals are not easily measured with conventional measuring activities. Using HFSS, engineers can analyze signal quality and timing relationships across the various nets that compose the memory interface of their infotainment system quickly, with extreme accuracy. Additionally, results can be generated at any point between the transmitter and the receiver.

In the case of a complex circuit board, for example, HARMAN has several transitions from one layer to another, then onto another integrated circuit (IC), then to a connector. The piece of copper between one IC and another is called the net. Signal probing of the net, which is required to test SI, is not always possible in a real physical application. If you have a multilayered printed circuit board with four to eight layers, you can’t always reach the inner layers to test the signal properly with a traditional measurement device. Using HFSS, HARMAN can do a digital probing of the signal at each of those nets to quickly and accurately verify that signal timing and behavior is tuned for optimal performance.

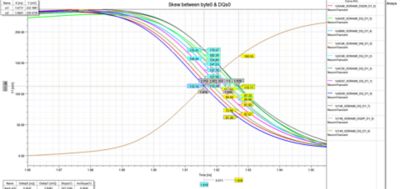

The skew simulation is the time delta between the clock and the signals associated to it. This simulation ensures that the signals in the same group will transfer the data at the same time and avoid the data valid window violation.

For Gitzinger, the benefits of using Ansys simulation software are easy to grasp. For his team, testing accuracy in a simulation environment enabled by real physics is the key to accelerating development while reducing costs.

“No one in the industry can afford to run unnecessary loops in hardware design because it takes months,” says Gitzinger. “Each time involves fixing the schematics, redoing the design, and then building new prototypes, which is a pretty expensive endeavor. So, we use Ansys HFSS tools to shorten the development lead time and keep costs at a reasonable level to be able to provide the best electrical performance we can.”

Read the case study for more details on HARMAN’s use of Ansys HFSS to support their connected car technology.