-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TOPIC DETAILS

What is Predictive Maintenance?

Predictive maintenance is a strategy that uses analysis of historical and real-time data from equipment to forecast when and where teams need to schedule maintenance. Predictive maintenance strategies offer significant advantages over more traditional methods like preventive maintenance or reactive maintenance through monitoring advanced algorithms to give maintenance teams the information they need to optimize their maintenance workflow.

Companies with a robust predictive maintenance program optimize their maintenance activities to avoid the cost of repairing equipment failures, reduce unnecessary maintenance, minimize unplanned downtime, and improve equipment performance.

The Key Components of Effective Predictive Maintenance Solutions

A good predictive maintenance strategy brings together several components that combine to guide maintenance teams in implementing a more proactive maintenance strategy.

- Historical data: The baseline for any maintenance system is historical information about equipment use, performance, maintenance, repairs, and replacement. Teams have used this data to create preventive maintenance schedules.

- Condition monitoring: Modern capital equipment uses real-time data collection as part of an Industrial Internet of Things (IIoT) implementation. Sensors on machines gather data and deliver it through a network to a central database where it is stored and analyzed. Condition monitoring captures more than whether a specific piece of equipment is working, how long it has been running, and how many operation cycles it has achieved. It also documents physical characteristics like temperature, load, vibration, sound, operating condition, and how well the device performs the task the supplier designed it to do.

- Predictive analytics: Once the system gathers data, the next step is to apply various types of predictive models to the data. This usually includes artificial intelligence (AI) methods, including machine learning (ML), as well as statistical analysis and other types of data analytics. More advanced implementations also leverage simulation models, including digital twins, to improve their prediction accuracy and detail. The goal of predictive analytics is to link monitored information with declining performance and breakdowns.

- Monitoring and recommendations: The system then combines the results of the predictive analytics with real-time monitoring to provide maintenance teams with the information they need to optimize their maintenance plan.

- AI/ML-enhanced functions: A growing component of effective predictive maintenance implementations is AI tools. AI/ML algorithms enable much more accurate predictions based on past behavior and are trained by data captured from IIoT sensors or generated through simulation. Additional AI approaches like neural networks and large language models (LLMs) can be used to interpret information, look for patterns or changes in patterns, and summarize data.

Predictive Maintenance Subtypes

Implementations of predictive maintenance technology can take many forms, based on how maintenance teams use the predictions for their system:

- Preventive maintenance: Following a time or usage-based plan is categorized as scheduled maintenance. This approach is best for situations where wear and tear on equipment is consistent and the team knows when maintenance is needed based on use only. Sometimes, equipment manufacturers define a schedule as a predetermined maintenance regime. Understanding predictive versus preventive maintenance is an important step in developing a maintenance plan to properly optimize the use of each type.

- Corrective maintenance: If a team repairs equipment when it breaks or performance drops, the team is engaging in corrective maintenance. This approach is best for equipment failures or performance issues that are easy to diagnose and repair.

- Condition-based maintenance (CBM): Scheduling maintenance when a monitored parameter indicates a problem is referred to as CBM. This is the most beneficial type of maintenance because it informs the maintenance team about a potential problem and allows the team to address the issue before it becomes a larger problem.

- Risk-based maintenance: Teams use risk-based maintenance to schedule and carry out maintenance based on the business risk of failure or unscheduled maintenance. Risk-based maintenance is the next step for many maintenance departments when they want to further decrease operational costs after implementing condition-based maintenance.

Data Collection Techniques in Predictive Maintenance Solutions

Another key component of predictive maintenance technology is the data collection methods used to monitor equipment. Here is a list of the most common techniques used to collect data:

- Acceleration and rotational velocity recording: This technique refers to the recording of acceleration from linear motion or rotating part forces on equipment that can reduce its lifespan. Changes in expected acceleration and rotational velocity can also indicate a growing issue.

- Acoustic monitoring: Monitoring the sound of machinery with microphones for acoustic analysis is one of the least expensive and most revealing ways to determine if the behavior of a machine is changing. Vibrations during normal operation give off a sonic signature, and when that signature changes, operators know that something has changed in the machine.

- Control system inputs and outputs tracking: The information created by the control systems used for automation produces inputs and tracks feedback from sensors that may not be part of an IIoT network. A comprehensive predictive maintenance solution includes capturing that data. Key metrics include operating time, cycles, input feeds and speeds, system performance, and response to commands.

- Electrical signals monitoring: The electrical signals in any electromechanical system exhibit variations in voltage spikes or current ripples if something changes in the system.

- Impurity and material property tracking in fluids: Many pieces of machinery include gases and liquids, or they use lubricants to reduce friction between moving parts. Excessive wear in a mechanical system can be indicated by metal flakes in lubricants, reduced viscosity from excessive heat, and impurities from leaky seals. Monitoring systems use oil analysis, fluid conductivity, and other nondestructive testing methods to capture changes in fluids of all types.

- Pressure sensors and load cells monitoring: The simplest way to measure loads on a mechanical system is to capture the pressure of fluids or the load on mechanical components.

- Temperature measurement thermography imaging: Most implementations of asset performance monitoring use sensor data from thermocouples or thermistors to measure the temperature of key locations in a system. They also deploy infrared cameras to create images capturing the temperature of any visible surface. Temperature changes are another inexpensive parameter to monitor that is a signature of potential malfunction.

- Vibration sensing: Another relatively inexpensive but insightful technique used in predictive maintenance systems is vibration analysis. Just as sound has a unique signature, changes to the vibration patterns in structural components are an indication that something has changed in the system.

The Influence of AI in Predictive Maintenance Implementations

AI-driven functions deliver significant capabilities that expand and enhance the impact of predictive maintenance across application cases. Although teams designing a predictive maintenance solution can leverage AI for any capability that interprets data, most applications can be classified in one of the following three areas:

- ML-based predictive analytics: ML algorithms form the core of many advanced predictive analytics tools. Solutions can use field data or simulation to create models that estimate how changes in input parameters affect output parameters. The deterministic nature of ML algorithms makes them ideal for predictions.

- LLMs for data query: LLMs investigate sensor data with query-based interfaces and assist human workers by creating detailed work orders, developing instructions for repairs, assisting with pattern detection, and enabling plant managers to perform "what-if" studies virtually before implementing solutions in real time. Further, LLM findings support operators and maintenance teams in digging deeper into data to spot changes or identify trends. The natural language aspect of LLMs eliminates the need for complicated user interfaces that require training while their summarization functions quickly ingest and interpret large datasets.

- Enhance pattern recognition with AI: Identifying data trends or deviations from expected patterns in sensor data is a key part of predictive maintenance. And both are strengths of AI tools, which replace or enhance human monitoring.

Positioning Predictive Maintenance Solutions in an Enterprise

Predictive maintenance technology can deliver significant cost savings and improve uptime if it is the right fit for a business. Companies must ensure that the return on investment from implementing a solution is enough to justify the cost. Before an enterprise of any size begins the process of implementing predictive maintenance, it needs to verify that the following characteristics describe its operations:

- The company has physical assets that require maintenance.

- Those physical assets have IIoT monitoring, or the enterprise is willing to invest in networked real-time monitoring systems.

- Spare parts and maintenance costs are a significant part of operating costs.

- Downtime for equipment maintenance or a failure has a significant negative impact on the company's business goals.

- The organization has a maintenance team or is willing to form one.

- Management is committed to investing in the people, processes, systems, and equipment needed to gather real-time data and act on the information it provides.

Any entity that has these characteristics can expect to see the following benefits of predictive maintenance:

- Cost savings for maintenance activities: The most direct impact of properly implemented predictive maintenance tools is a reduction in the number of maintenance tasks. With preventive maintenance, teams may conduct maintenance tasks even when not needed. With data-driven scheduling, those teams need only take action when required. In addition, the team knows how urgent a given maintenance task is, and the team can schedule tasks based on priority and efficiency.

- Fewer repairs and replacements: By identifying a potential failure before it happens, predictive maintenance can drastically reduce a company's costs for repairing and replacing broken parts.

- Greater system uptime: Disruptions to production are not only costly but can cause issues throughout the organization. The output from predictive maintenance tools lets teams schedule maintenance when downtime causes the least negative impact, and the information reduces downtime from equipment failures.

- Reductions in maintenance planning time: The detailed, actionable information provided by predictive maintenance solutions helps the maintenance team streamline the whole process of scheduling and managing maintenance. Companies that integrate their predictive maintenance software with their computerized maintenance management system (CMMS) and asset management tools can see even greater reductions in planning time because the information resides in one place.

- More cost-effective spare parts management: A facility with a large amount of equipment may need to keep a large number of spare parts in inventory to address unnecessary preventive maintenance or component failures. With a proactive predictive maintenance strategy, that facility can move to a just-in-time inventory system where it orders parts only when the system alerts it to an upcoming need.

- Optimized asset performance: The final benefit of predictive maintenance is better performance of the equipment maintained by an enterprise. Engineers can use the data produced to identify declining performance even when maintenance is not needed. Additionally, a work order can still be issued to make changes that improve the asset’s condition.

Challenges in Deploying Predictive Maintenance Systems

Companies will face numerous challenges when implementing a predictive maintenance system, but knowing those challenges upfront will help them plan and create strategies to overcome them. The most significant challenges are:

- System infrastructure: Predictive maintenance systems use data from sensors across equipment. Over time, the information technology (IT) infrastructure needed can be significant. Cloud or on-premises data storage needs to accommodate a significant amount of data, so network engineers must tie the IIoT sensors and equipment control systems to the data storage infrastructure, and the implementation team must provide sufficient computer horsepower for data analytics and simulation.

- Improved safety: Equipment failures can be hazardous. Many machines operate at high temperatures, are under significant pressure, and store a large amount of potential or kinetic energy. Predictive maintenance allows teams to remove potential safety issues before they happen.

- Workforce training: Most organizations train maintenance technicians and engineers to carry out scheduled maintenance. With predictive maintenance, the training can focus on being more flexible and on how to work off of data-driven insights, reacting to information provided by monitoring, predictive analytics, and simulation.

- Data requirements: The predictive analytics and condition monitoring used in predictive maintenance systems require a significant amount of data over time. Without consistent data, engineers can’t train ML systems or identify changes and trends in the data.

- Complexity: Predictive maintenance systems are complex because they combine a wide variety of sensor technology, data science, AI, equipment life cycle management, and maintenance scheduling under one comprehensive system. In many cases, that system addresses the needs of a wide range of machine types.

Three Predictive Maintenance Use Cases

Many industries can benefit from predictive maintenance systems, but anyone considering adding or growing their solutions in this area can benefit from looking at the following three applications:

1. Natural Gas Power Turbines

In 2023, 23% of the world’s electricity came from power turbines fueled by natural gas. These power turbines are a subset of turbomachinery that convert the combustion of natural gas into a rotating shaft that powers a generator. They contain many components that can fail because of heat, vibration, poor lubrication, and wear and tear on components that run constantly. Any downtime for a power turbine is money lost for the company operating these complex, expensive systems. In addition, the large rotating disks can fail catastrophically, damaging the entire system and the surrounding facility.

Maintenance teams use a combination of acoustic, thermal, and vibration monitoring, as well as tracking operating parameters, to look for any deviations that indicate a potential failure. Teams can use AI-based predictive analytics, combined with detailed physics simulation, to convert these signature signals into a diagnosis of where the problem is developing. Armed with this information, the maintenance team can repair the system long before a failure occurs or performance starts to drop.

2. Heavy Equipment

Another area where predictive maintenance is delivering a strong return on investment is the heavy equipment used in construction and mining. Because these machines operate in the field, repairs are even more expensive, and the right parts may not be anywhere near the equipment. Modern heavy equipment uses IIoT devices to monitor almost every subsystem in the equipment and upload it via broadband to databases that capture output from large fleets of vehicles.

3. Vehicle Fleet Management

Another area where predictive maintenance shines is in fleet vehicle asset management. The margins generated by fleet vehicles can be small, so any downtime can directly impact the bottom line. Most modern vehicles have the sensors needed to track the assets in the fleet. Fleet management teams simply need to gather data and apply predictive maintenance tools to develop a model that identifies potential issues before they arise.

Using Simulation to Improve Predictive Maintenance

More and more companies are integrating simulation in their set of predictive maintenance tools with the use of digital twins, as well as detailed physics modeling. Companies can use these virtual representations of their equipment in a wide variety of ways to understand what sensor signals to look for, what changes in the signal imply, and what the optimal workflow is to implement repairs.

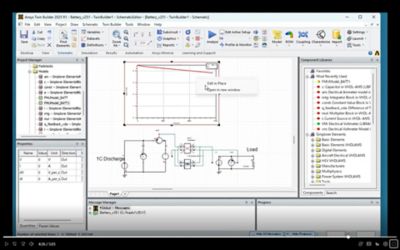

The first step in upscaling a predictive maintenance solution with simulation is to create and deploy digital twins with a tool like the Ansys Twin Builder simulation-based digital twin platform. These system-level models use a mathematical representation of each subsystem in a piece of equipment based on empirical data, an equation, or a physics model. Once deployed, operators can see how changes to inputs affect the outputs they are monitoring. This allows them to troubleshoot a required change in the system or try out different solutions to problems they are seeing in the field.

An example of a system-level digital twin in the Ansys Twin Builder simulation-based digital twin platform

The teams responsible for predictive maintenance can also combine physics-based simulation models with real-world data in a platform like Ansys TwinAI AI-powered digital twin software. This tool uses the latest ML algorithms to pull insight from complex systems in a hybrid approach to create a virtual mockup of equipment.

Sometimes, more capability is needed for system-level modeling to accurately represent the behavior of a machine that can benefit from predictive maintenance. In these situations, engineering teams leverage model-based systems engineering (MBSE) with a comprehensive simulation platform like Ansys ModelCenter model-based systems engineering software. The extra level of capability and flexibility while supporting industry standards for systems models can quickly and efficiently deliver actionable insights.

When accurate behavior is needed, engineering teams deploy physics-based simulation tools at the component or assembly level. They may deploy a comprehensive tool, such as Ansys Mechanical structural finite element analysis software for structural, thermal, and vibration analysis or Ansys Fluent fluid simulation software for fluid modeling. Both can help diagnose acoustic signatures. Users can also connect these two tools to represent fluid-solid interaction.

Related Resources

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.