Case Study

-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

“Using Ansys simulation tools, we saved significant time and costs by addressing electromagnetic compatibility issues early in the design phase. This approach optimized performance and ensured compliance with industry standards.”

— Mauro Barbieri

Endurance Race Cars - Head of Performance, Ferrari

For the third year in a row, Ferrari’s 449P Hypercar triumphed at 24 Hours of Le Mans, placing first (#83), third (#51) and fourth (#50). Pictured above, no. 51 driven by A.Pier Guidi, J. Calado, A. Giovaniazzi

Challenges

To design an e-powertrain system for its 499P Hypercar, Ferrari must first overcome several electromagnetic interference (EMI) and electromagnetic compatibility (EMC) challenges. Specifically, as this technology transitions to wide-bandgap semiconductors, the higher switching frequencies and reduced component sizes result in increased conducted and radiated emissions. These emissions can disrupt the functional behavior of an electric powertrain’s components, compromising overall system performance. Resolving any related system challenges was previously done by the Ferrari engineering team via physical prototypes, which often increased development costs, delays, and risks.

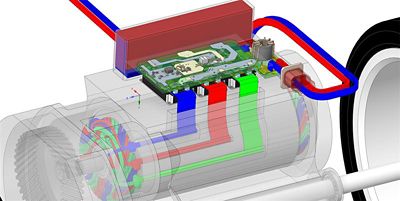

E-powertrain system geometry

Synopsys Solution

- Ansys SIwave™ printed circuit board (PCB) and package electromagnetics simulation

- Ansys HFSS™ high-frequency electromagnetic simulation software

- Ansys Q3D Extractor® parasitic extraction electromagnetic simulation software

- Ansys Icepak® electronics cooling simulation software

- Ansys Electronics Desktop (AEDT)™ electronics systems design platform

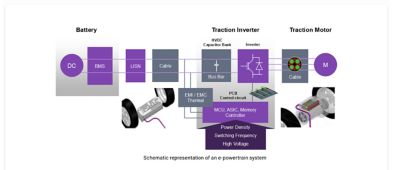

Schematic representation of an e-powertrain system

Benefits

- Optimized overall e-powertrain system performance by integrating Ansys tools for accurate modeling of power modules, PCBs, and EMI filters

- Ansys offers accurate solvers for numerous automotive electronics and EMC applications integrated in AEDT — a unique solution that’s easy to implement and automate

- Enhanced thermal management and energy flow in the powertrain system, which improves efficiency while increasing reliability and performance

- Reduced design time and costs by identifying and resolving EMI/EMC issues during the design phase, eliminating the need for extensive physical prototypes

- Regulatory compliance for conducted and radiated emissions, validated virtually before physical testing

- Significant reductions in physical prototypes and expedited automotive regulatory compliance, enabled by early-stage validation

Overview

Racing hybrid powertrains represent one of motorsport’s most sophisticated engineering achievements, as they combine traditional internal combustion engines with advanced electrical systems. To be effective in a competitive environment, they must deliver exceptional performance while managing multiple energy sources and complex power flows. Ferrari used advanced simulation tools to enable early-stage EMI/EMC optimization for the e-powertrain systems of its sports cars and race cars. These tools helped the original equipment manufacturer (OEM) reduce testing costs and compliance challenges while simultaneously ensuring the superior performance this iconic brand is known for.

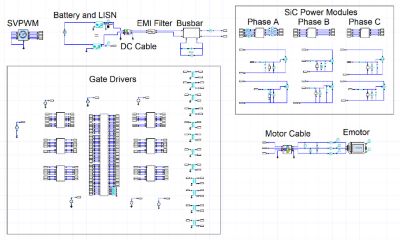

Complete inverter circuit with all the main components, including LISN and CISPR 25 EMI receiver

Radiated emissions of the inverter part. The electrical and magnetic field can be visualized at all frequencies.

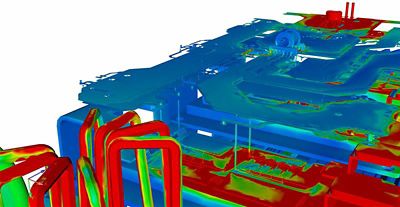

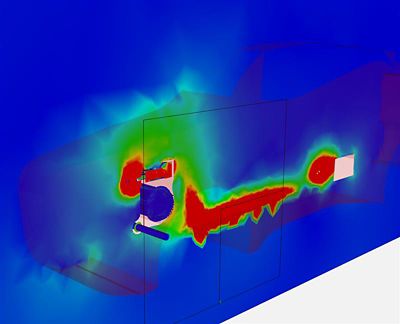

Radiated emissions of the e-powertrain with battery cables and complete car geometry

Comprehensive Simulation Workflow for EMI/EMC Design

To meet evolving regulatory standards and enhance system performance, Ferrari needed a reliable, simulation-driven approach that identified and resolved EMI/EMC challenges early in the design process. Ansys, part of Synopsys, provided a comprehensive virtual simulation workflow of integrated Ansys tools including Ansys SIwave software, Ansys HFSS software, and Ansys Q3D Extractor software to improve printed circuit board (PCB) layouts, model parasitics, and simulate thermal and electromagnetic behavior.

This success was enabled by:

- Simulations of PCBs, power modules, and EMI filters using SIwave software and HFSS software for better EMC and thermal performance

- Quasistatic solvers in Q3D Extractor software to analyze partial inductance and resistance in busbars and cables

- State-space modeling in the AEDT environment to evaluate time-domain behavior and validate EMI filters prior to production

- A unique electrothermal workflow for power losses in the power electronics thermal management with Q3D Extractor software and SIwave software coupled with Ansys Icepak

- As a result of the new workflow, Ferrari engineers can predict and manage EMI/EMC and thermal at both the component and system levels

“The integration of simulation up to the final phase of testing in a complete vehicle allows the development of a more efficient, safer and compliant hybrid powertrain, ensuring high-level performance in the most demanding competitions.”

— Mauro Barbieri

Endurance Race Cars - Head of Performance, Ferrari

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.