Case Study

-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

“By integrating Ansys simulation tools into our engineering process, we unlocked a new level of innovation and validation for our STEM Racing project. Using Ansys Fluent software, our computational fluid dynamics (CFD) results closely aligned with those from our wind tunnel testing, confirming the accuracy and reliability of our aerodynamic refinements. Employing Ansys Mechanical software, we ensured our custom four-axis CNC machine’s design could withstand the operational stresses required for precise manufacturing.”

— Aisas Tatsis

Team Leader and Engineer, PiForce

Designing a high-performance miniature Formula One car involves complex aerodynamic, structural, and manufacturing challenges. Engineering simulation is vital in streamlining the car’s development, quickly identify optimal configurations, and refine concepts with confidence. Using Ansys, the student team PiForce overcame performance and production hurdles, accelerated design iterations, and gained invaluable real-world simulation experience. The team understands that continuous innovation and leveraging technologically advanced tools enables them to truly stand out and excel.

Challenges

The team aimed to create the fastest, most aerodynamically efficient car possible, in which even the slightest improvement could offer a decisive advantage. In a sport where every millisecond matters, simulation enabled them to refine details and outpace the competition. PiForce integrated Ansys Fluent results into their custom software to understand each design’s holistic performance, ensuring they selected only the most potent configurations. The competition criteria demanded robust, accurate, and reliable tools capable of delivering actionable insights, providing the competitive edge they needed.

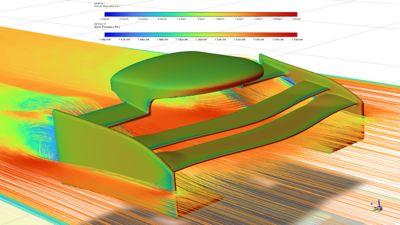

Figure 1. Computational fluid dynamics (CFD) simulation and visualization using pressure path lines and surface pressure indication on the front wing (red: high pressure; blue: low pressure)

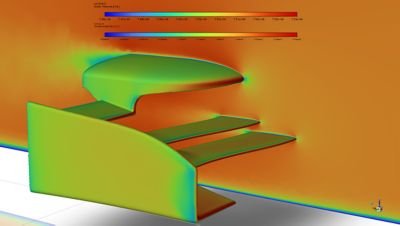

Figure 2. CFD simulation and visualization of the air velocity on the vertical plane of the front wing (red: high air velocity; blue: low air velocity)

Engineering Solutions

Using computational fluid dynamics (CFD) capabilities in Fluent software, the team was able to:

- Precisely model airflow, pressure distribution, and aerodynamic forces around the car designs

- Receive quick comparisons of multiple geometry variations, which enabled the team to refine shapes and improve aerodynamic efficiency

- Compare results with wind tunnel data, confirming that the CFD-driven improvements were accurate and reliable

- Incorporate Fluent results into the team’s custom software, providing a holistic view of each design’s overall performance and guiding data-driven decision-making

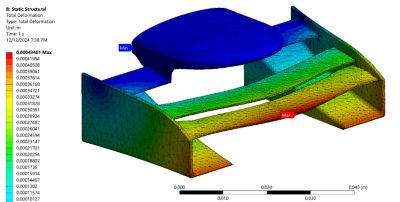

Figure 3. Ansys Mechanical finite element analysis (FEA) simulation of the front wing of the car, which was used to predict the car’s behavior during impact

Ansys Mechanical software enabled the team to:

- Ensure their custom four-axis CNC machine’s components could withstand operational stress, securing its durability and precision

- Minimize reliance on physical prototypes, which not only shortens development time and optimizes material usage but also ensures that the construction withstands stress and strain effectively

Benefits

- By leveraging virtual testing, PiForce reduced design cycle times by approximately 40%, enabling them to refine concepts more rapidly than relying solely on physical prototypes.

- Engineering simulation helped identify key aerodynamic improvements, resulting in an estimated 12% increase in overall aerodynamic efficiency.

- Integrating simulation results into the team’s custom software provided precise, actionable insights, which enabled them to confidently select the fastest, most efficient design.

- Using professional-level simulation tools gave the team industry-relevant skills, enhancing their engineering knowledge and strengthening their competitive advantage.

- These optimizations and rapid iteration cycles translated into improved on-track performance, setting the team apart from others and directly contributing to their award-winning results.

Figure 4. Visualization of the final car, which the PiForce team raced at the 2024 Aramco F1 in Schools World Finals

Figure 5. Team photo at the awards ceremony with the Chair of Judges Recognition of Achievement award

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.