Case Study

-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

“Ansys is essential to designing a high-performing STEM racing car. Without it, we’d rely on intuition alone. With Ansys, we can simulate and validate concepts, turning abstract ideas into precise, real-world solutions. It bridges theory and application, helping us test and refine designs with accuracy. Its user-friendly interface and compatibility with home computers make the brainstorming and iteration process fast and accessible. This efficiency empowers us to innovate quickly and effectively, making Ansys a key driver of progress in STEM engineering.”

— Maxime Muller, Design and Simulations Engineer, Tachyon Racing

STEM Racing (Formerly F1 in Schools) is an international STEM-based competition in which teams of 3-6 students, aged 9-19, design, build, and race a miniature Formula One (F1) car along a 20-meter track and compete for optimal lap times. During the competition, teams are expected to utilize a gamut of high-end software to their advantage in hopes of optimizing the performance of their car on the track. This can range from manufacturing to computational fluid dynamics (CFD) software.

For Paris-based student team Tachyon Racing, Ansys simulation software was crucial, as the team did not have access to a physical track. This meant that most tests were conducted virtually through Ansys software on local computers. This not only accelerated the design cycle but also gave the team a competitive edge in fine-tuning their vehicle’s performance under different racing scenarios.

Challenges

The primary challenge for Tachyon Racing was optimizing the aerodynamics of their chassis, particularly evaluating the effectiveness of their dimple and vent designs. Using Ansys simulations, the team was able to test and refine these features, ensuring smooth airflow transitions across the car and minimizing turbulence to improve race performance. Through this process, Tachyon Racing discovered that elongated dimples, rather than shorter ones, provided better aerodynamic results — something they wouldn’t have known without simulation. As an independent team without access to expert guidance, Tachyon Racing found that Ansys was the most accessible and effective solution thanks to its ability to run locally and its extensive online learning resources. These tools enabled the team to independently learn, test, and apply data-driven improvements to their design.

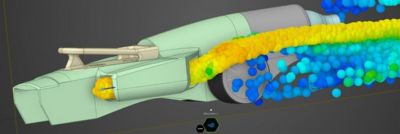

A simulation of the first prototype of the vents

Engineering Solutions

Ansys Discovery software enabled the team to optimize the car design to reduce drag forces and identify high-pressure areas to minimize them. Furthermore, Ansys Fluent software enabled them to confirm their design innovation idea of adding vents. Air that would have hit the wheels was redirected to the underbody of the car, avoiding drag caused by the Magnus effect.

Tachyon Racing thoroughly utilized Ansys’ simulation software during the design process of the many iterations of their side pod vents:

- Straight: directing the air directly to the rear of the chassis

- Downward: directing the air to the underbelly of the chassis

- Inward: directing the air to the central underbody of the chassis between the wheel axes

Through the aid of Ansys simulations, the team deduced the following: while straight slits excel at minimizing drag and downward slits reduce mass the most, inward slits were the best choice because of their mass-saving benefits and ability to redirect airflow that would cause drag. In other words, simulation showed that inward slits prove to be a beneficial compromise between the team’s previous straight and downward vent designs, offering the advantages of both.

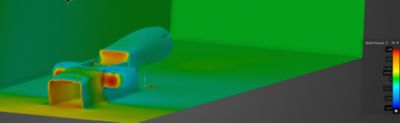

Ansys simulations were also at the core of some of the design changes to the side pod surfaces. The car’s initial side pod design featured a flat front. After numerous simulations, however, the team found that this created air pockets between the side pod and the wheels, meaning that air would be trapped. This would create a region of high-pressure air that would be detrimental to the aerodynamics of our car. Therefore, Tachyon Racing modified the shape of the side pods and smoothed out the front, which made a drastic difference.

A pressure simulation on one of the final versions of the chassis

Benefits

One of the biggest challenges the team faced was manufacturing. Due to multiple issues with their supplier, there was a three-month delay between completing the initial chassis design and placing the final order. This setback made it impossible to rely on traditional physical testing, especially with the tight competition schedule. Even a single round of testing would have taken at least two weeks. Ansys solutions were essential during this period, enabling the team to run simulations to optimize the chassis and evaluate design changes quickly.

In total, Tachyon Racing went through seven major design iterations, along with countless smaller adjustments in between. Ansys software gave the team the freedom to run unlimited virtual tests, helping them analyze individual components and their aerodynamic effects (such as the Magnus effect) with a high level of accuracy. These insights enabled them to make informed decisions with confidence and refine their design under tight time constraints.

Today, Ansys continues to be a key part of the team’s workflow, with team engineers both using it for personal projects and as a valuable teaching tool when mentoring new teams.

Renders of Tachyon Racing’s Nationals and World Finals cars, respectively