-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

Ansys for Ferrari Challenge

A Partnership We Can Trust

Ferrari Challenge: Innovating and Winning with Ansys Simulation Technologies

Ferrari's commitment to the track has always extended well beyond the world of Formula 1 to include GT racing. Competitions are part of Ferrari’s DNA. To be an innovative leader in the sport, Ferrari synergizes its efforts across different divisions.

Without simulation it would be virtually impossible to deliver results with the limited time frame available. Ferrari’s continuous investments in engineering simulation can be seen in the performance we achieve on the racetrack.

Ferrari Competizioni GT: Innovating and Winning with Ansys Simulation Technologies

Our collaboration with Ansys started in 1998, when we were pioneering simulation tools to support the work of aerodynamicists. Simulation was a key advantage for us. As we grew our engineering team and its expertise, our expectations for Ansys also became more demanding. Our relationship with Ansys has kept growing, and in the last few years we have achieved unprecedented alignment in our vision for the evolution of a technical roadmap. Ansys has been a key technology partner in achieving our success.

Video Date: 2018

Ansys Ferrari Videos

James Calado

James Calado - 2018

Ferrari Competizioni GT Driver

Ferdinando Cannizo

Ferdinando Cannizzo - 2018

Head of GT Racing Car Development

Sam Bird

Sam Bird - 2018

Ferrari Competizioni GT Driver

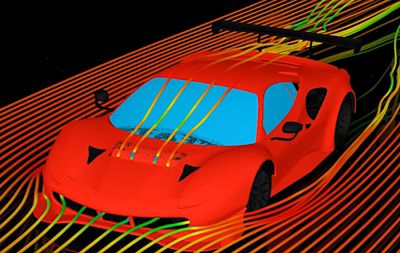

Aerodynamics

Our collaboration with Ansys started in 1998, when we were pioneering simulation tools to support the work of aerodynamicists. “Our relationship with Ansys has kept growing, and in the last few years we have achieved unprecedented alignment in our vision for the evolution of a technical roadmap. Ansys has been a key technology partner in achieving our success"

Connectivity

Ferrari Competizioni GT is looking to 5G and Ansys simulation technology to boost connectivity and optimize data flow to leave their competition behind.

Optical Systems

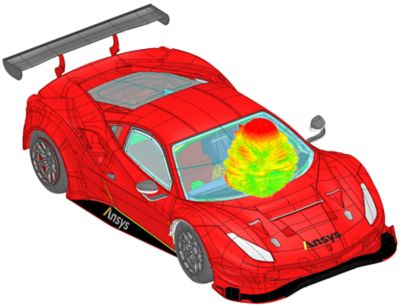

Material Intelligence

Materials Digitization at Ferrari was driven by the need to accelerate materials innovation and utilization for faster adoption into vehicle design, as well as to ensure every engineering team across Ferrari used the latest material dataset in their design (CAD), simulation CAE (computer-aided engineering), and product life cycle management (PLM) tools.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.