-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

July 7, 2022

Optimize Your Entire Electronic System Design and Everything Connected to it

You probably know that optimization software can provide better solutions than experience alone — and that it can get there 10x or even 100x faster than the old, manual workflow of design, prototype, test, refine, and repeat. Optimization software automates the process of virtually testing hundreds, if not thousands, of scenarios to identify the best candidates, so it’s no wonder that the performance improvements can be off the charts. But automating individual processes is yesterday’s news.

Today’s complex system designs require engineers with expertise in several disciplines — electromagnetics, computational fluid dynamics, structures, and more — to work together to optimize entire systems. To add to the level of difficulty, they are using different computer-aided design and engineering (CAD/CAE) software tools to fine-tune the design and simultaneously simulate different physics. That’s no small task, especially considering that different engineers often use software from different companies. Even more, making an adjustment to optimize for one type of physics might result in a suboptimal solution for a previously optimized type of physics, sending the design back for further optimization and creating a lengthy ping-pong effect. To tap into the power of automated optimization, you need an open, CAD/CAE-agnostic solution that orchestrates an efficient workflow across engineering disciplines and physics.

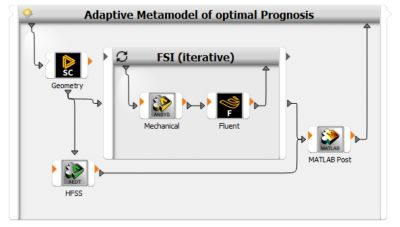

An Ansys optiSLang toolchain connecting multiple physics solvers

Optimization Made Easy and Open

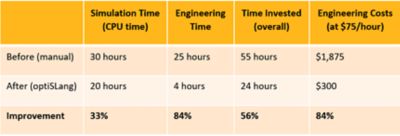

Leading companies have been using Ansys optiSLang to do just that for decades, increasingly relying on its constantly updated capabilities — including a decade of artificial intelligence and machine learning (AI/ML) advances — to tackle complex engineering problems faster. One antenna and radar product vendor connected optiSLang, Ansys HFSS, and Microsoft Excel to reduce engineering time and associated costs by 84%, resulting in an improved design.

While new innovations increased systems complexity, optiSLang has become even easier to use. You don’t have to be an optimization expert to benefit from optiSLang. You can use the simple drag-and-drop interface to connect design tools, whether you’re using our competitor’s solvers, products from our partners, or our own leading solutions like HFSS for electromagnetic simulation, Ansys SIwave for signal and power integrity (SI/PI) analysis of printed circuit boards, or Ansys Lumerical and Ansys Speos to simulate photonics and optical systems.

Optimization results for a differential via

Integrate Systems of Systems

System engineering isn’t limited to electromagnetics and SI/PI analysis, and neither is optiSLang. Mechanics, fluids, and noise, vibration, and harshness (NVH) can all be orchestrated and automated with optiSLang.

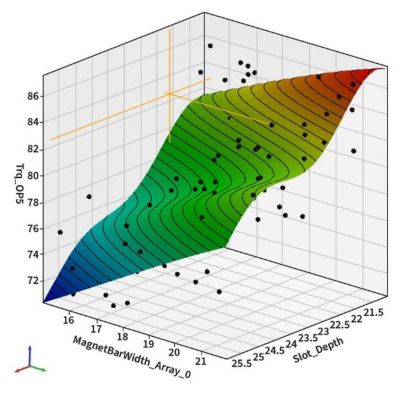

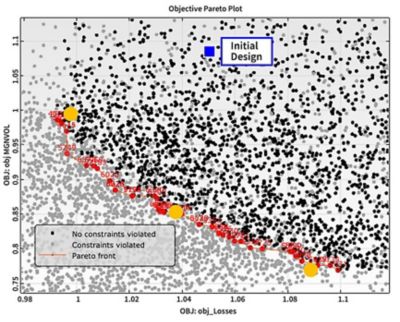

For example, Schaeffler Group coupled Ansys Motor-CAD electric motor design software with optiSLang to help create a computationally efficient workflow to enable multiphysics, multi-objective design optimization of electric machines. To generate results far faster, Schaeffler computed a metamodel in optiSLang, then used the software to also run the optimization. That enabled them to run thousands of optimization iterations within minutes.

Meta-model visualization of the relationship between two geometry parameters and the continuous torque.

Pareto front, multiple optimal design concepts demonstrating a trade-off between e-machine cost and drive cycle efficiency. Images courtesy of Schaeffler Group

“By coupling front-loading methodologies, Schaeffler created an efficient and flexible tool that enables product designers and engineers to use the same optimization workflow for any electric machine concept — and to have results in minutes,” writes Pierre Millithaler, Schaeffler Automotive Buehl GmbH & Co. KG. “Instead of it taking 50 hours to simulate 100 samples using finite element analysis (FEA), the metamodel-based optimization can simulate 10,000 samples within minutes.”

Learn More at DAC 2022

Visit us in booth 1539 at this year’s Design Automation Conference (DAC), from July 10-14 in San Francisco. Ansys experts will present during the following discussions:

- “AI/ML Adoption within the Semiconductor Industry: Disruptive Power Integrity & Reliability Analysis”

- “Tackling SI/PI/TI Design Optimization Challenges with Parametric Modeling and AI/ML”