-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

May 16, 2023

Havells India Clears the Air using Ansys CFD Simulation

As in many other parts of the world, air quality is a big problem in India, especially in the north of the country, where the air quality index (AQI) frequently reaches greater than 100, which is considered unhealthy for sensitive groups. Havells India Ltd. decided to enter the air purifier market to help solve this problem. But they were not looking to make another standard product that would be indistinguishable from the competition. Ashit Kumar, senior manager, computational fluid dynamics (CFD) simulation at Havells, says that the company wanted to “delight” their customers and produce an air purifier that was “aspirational.”

So, Havells Studio designed the Meditate Air Purifier to be a high performance, aesthetic addition to any room, with advanced features like a titanium dioxide (TiO2) photocatalytic module to break up volatile organic compounds (VOCs). They created a detachable sensor that monitors the AQI near your sitting location, instead of the AQI near the purifier itself. You can even recharge your cellphone by placing it on top of the purifier in place of the detachable sensor.

Most importantly, they used Ansys CFD simulations to ensure that airflow through the three stages of the purifier — the case and high-efficiency particulate absorbing (HEPA) filter, the blower, and the TiO2 module — was optimized for maximum purification capabilities.

“This optimization could not have been done without CFD simulations, because there were so many interconnected parameters to understand,” Kumar says. “Ansys Fluent helped us to monitor the airflow in all three stages of the purifier and adjust the design until we had optimal flow conditions in each segment.”

A Tale of Three Stages

Havells’ Meditate Air Purifier is built in three stages, starting with a HEPA filter at the bottom, a vaned rotor, or “blower,” in the middle, and a TiO2 photocatalytic module on top. The spinning rotor draws air up through the HEPA filter, where particles of various sizes are captured and filtered out. This air then rises past the blower into the TiO2 module, where UVH and UVC wavelengths of light shine on the TiO2 catalyst, which adsorbs volatile organic compounds (VOCs) and breaks them down into smaller, nontoxic components.

While it may initially seem like moving the largest volume of air through the purifier unit is desirable to clean more air quickly, each stage of the purifier has requirements that make this unrealistic. In the HEPA filter, the pressure drop increases with increasing air velocity, so the airflow must be moderated to keep the pressure drop down.

A major consideration of the blower is the noise generated by the quickly spinning rotor. Because the purifier is used in household rooms, it must be relatively quiet so as not to bother the occupants. This limits the operational speed of the blower and also dictates its design.

In the top stage, VOCs are adsorbed onto the surface of small TiO2 catalytic particles. While adsorbed, UVH and UVC light impinges on the VOCs, which are broken down photocatalytically. But for this to occur, the VOCs must spend a minimum residence time on the surface of the TiO2. If the air is moving too fast in this stage, the VOCs will bypass the TiO2 catalytic particles and exit the purifier unchanged and still toxic. Because only one airflow velocity is maintained throughout the purifier, the needs of each stage must be taken into account to optimize the purifier’s performance.

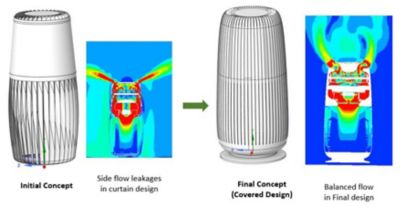

Figure 1. CFD simulations of the initial design and the final covered design of the outer casing. The HEPA filter is the cylindrical-shaped blue element at the bottom in the simulations.

A Three-Stage CFD Simulation Approach

Selection of purification filter (HEPA Filter) and Outer Casing Design

The design of the porous HEPA filter controls the pressure drop and makes guiding the flow of air from inside the purifier to outside challenging. It directly affects the amount of particulate material crossing the filter and affects the blower requirement to suck the air inside and guide it outside.

“We used Fluent to help us determine the proper thickness, height, and position of the HEPA filter,“ Kumar says.

In the initial design of the outer casing (see figure 1), the simulation showed that some of the air escaped out of the sides of the purifier unit, before reaching the top catalytic purifier unit. This meant that some particulates and VOCs were passing into the ambient atmosphere, to be breathed in by anyone in the room. Part of this was due to the thickness of the filter itself.

In the covered design, the HEPA filter — the cylindrical-shaped blue element at the bottom of the simulation images — was made thicker at the bottom and sides. In combination with the new casing design, the simulations showed that all airflow remained inside the purifier, exiting from the jets at the top after all purification had been completed.

Blower Design

The design of the blower directly affects the flow field, power requirements, and noise level of the purifier. It also determines the velocity and location of the airflow through the TiO2 catalytic and UV purifier above the blower. Ideally, the blower should provide a flow through the center part of the TiO2 module at the highest velocity possible while still leaving enough time for the catalyst to break down the VOCs.

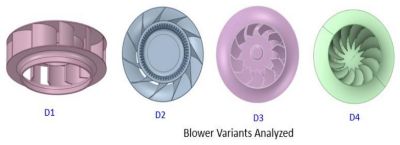

Figure 2. The four blowers investigated by Havells engineers.

Havells engineers looked at four blower designs (see figure 2) and the flow patterns they caused through the purifier using Fluent. While design D2 originally showed the best flow pattern and velocity for delivering the air to the catalytic module, it was too noisy.

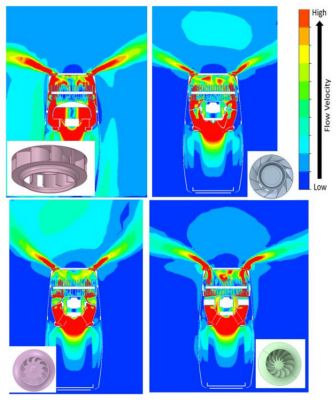

Figure 3. Ansys Fluent simulation for flow characteristics of the four blower designs.

Eventually, through a process of optimization, Havells chose design D1 as giving the optimal balance of flow velocity, flow location, and noise level for their Meditate Air Purifier.

Figure 4. Simulations performed for blower optimization. The blower is in the center of these images. The dotted circle above the blower shows airflow through the TiO2 catalytic unit.

Orientation of TiO2 Module

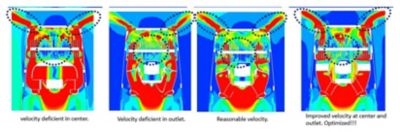

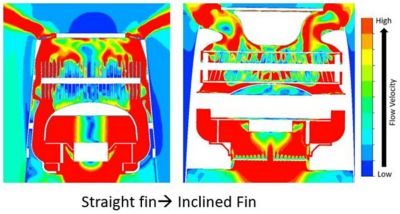

The TiO2 catalytic unit consists of parallel fins of a substrate containing the TiO2 particles. Originally, Havells engineers arranged these fins in a circle with all fins at a 90-degree angle to the blower; that is, they were standing straight up. But the flow was not optimal with this design.

“If your flow is very fast through the TiO2 module, the catalytic reaction will not happen; also, if the flow is very little and slow, it will separate and not reach to the top, causing stagnation,” Kumar says. “It has to be in the range of 0.5 meters per second to 1.5 meters per second so that the catalytic reaction can take place.”

By tilting the fins inward at an angle, they improved the flow intake through the module and achieved the desired flow velocity range. The top section of the “straight fin” image in Figure 5 shows lower flow at the center, which means purification is limited to the side plates, with the center ones playing no role. The “inclined fin” image shows much improved flow with adequate velocity through the plates as well as at the outlet.

Figure 5. Switching from parallel, perpendicular fins in the TiO2 module (vertical lines through horizontal white bar about two-thirds up in the simulation image on the left) to angled fins (same location on right image) produced optimal flow.

Simulation Achieves the Right Balance

Using Fluent simulations, Havells engineers achieved the optimal airflow for all three stages of their Meditate Air Purifier, balancing the conflicting demands of pressure drop, noise, and residence time in the TiO2 module for optimal air purification.

“Adoption of digital technologies like Ansys Fluent simulations can help in designing the right product in the first attempt, which leads to a faster time to market and delivering the right mix of performance, quality, and cost,” Kumar concludes.

See how Ansys Fluent can help you.