-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

September 28, 2022

F1 in Schools: Inspiring High School Students to Become Future Engineers, One Race at a Time

Open up an official Pinewood Derby car kit and you’ll likely find a block of wood, plastic wheels, and four nails that serve as axles to get you rolling. Racing to victory depends on a winning combination of skill, gravity, and luck, influenced by the shape of the carved block, the greasing of the axles, and the careful placement of lead weights or pennies. For many kids, pinewood derby racing is considered both a rite of passage and a hands-on engineering opportunity. With support from the Ansys Academic Program, today’s Formula One science, technology, engineering, and mathematics (STEM) competitions offer kids ages 11-19 the chance to build on these and other fundamental engineering skills in new and exciting ways with simulation.

Exploded view of Team Sonic Boom World Finals car

Three of the six members on Team Sonic Boom from the Graf-Rasso Gymnasium in Fuerstenfeldbruck, Germany and the Gymnasium Grootmor in Hamburg, Germany were eager to share their experience and the value of F1 in Schools competitions. Team Sonic Boom, like many teams, come directly to Ansys to partner and gain access to our software and support for student teams. After hearing them talk about their personal accomplishments on Team Sonic Boom, it’s easy to conclude the group is exceptional by just about “any-typical-teen” standards. Many of them have been involved in F1 in Schools since the eighth grade, including Anas Izaaryene, the team’s manager.

“We’ve learned so much as a team over the years,” says Izaaryene. “I’m thinking about those things that directly link to the competition, including the computer aided design (CAD), safety, and simulation software we used to do analysis on the car. But there have been so many other amazing learning opportunities you might not think of working on a team and the bonds that form communicating with team sponsors and professional engineers involved in Formula One racing.”

Building Excitement Around Science, Technology, Engineering and Math (STEM)

F1 in Schools Ltd. is a nonprofit created in 1999 by partners who remained committed to delivering an exciting and challenging educational experience through the appeal of Formula One racing and to raise awareness of STEM around the world. Student teams participate in this global, multi-disciplinary challenge using engineering software to collaborate, design, analyze, manufacture, test, and ultimately race miniature compressed-air-powered cars of the future on a 20-meter-long track. Each car is manufactured from a single F1 polyurethane-material-based block kit.

During the initial design phase, participating teams use 3D CAD software to create a car subject to specifications set by the International Rules Committee. Vehicle aerodynamics are then analyzed for drag coefficient in a virtual wind tunnel using computational fluid dynamics (CFD) software. This analysis is followed by a detailed evaluation of overall machining strategy in 3D CAM, and additional wind and smoke tunnel testing. Each team has to create an informative display showing their work and must prepare for a verbal presentation to a panel of judges. Apart from their design, student teams are required to put together three 10-page portfolios documenting their marketing strategy, the project management, and the engineering of their cars. They are also expected to raise and manage sponsorship funds designated for research, travel, and accommodations.

Ansys CFD Software Drives the Winning Design

As the members of Team Sonic Boom will attest, a lot of effort and engineering work goes into creating a vehicle during the design phase, which was made easier by using Ansys Fluent CFD simulation software and Ansys Workbench workflows. Using Ansys software, the team imported their model and prepared it for simulation. The next step was to create a virtual wind tunnel, assign all the surfaces, name the model, and prepare it for the next steps. Fluent is then used to do meshing — the process of breaking down the continuous geometric space of the model into thousands of smaller elements to further define the physical shape of their vehicle design.

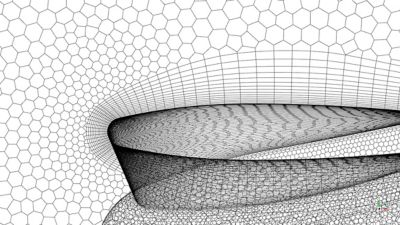

Meshing of rear wing in Ansys Fluent

“At a certain point during the design process, we realized we needed very accurate simulation to compete effectively, so we contacted Ansys,” says Florian Wolf, design engineer for Team Sonic Boom. “The first big thing we noticed was the impact of meshing with Fluent. It was a complex process, which took us about two or three months, but once we mastered it, we saw really positive results overall for our design, and got some great professional experience using simulation too.”

Going Through the Motion with Ansys Fluent

F1 in Schools competitions are the culmination of many engineering efforts. For Team Sonic Boom, getting started required setting up a development plan for the car first. Team member Jakob Rauh was responsible for research and development, organizing testing days on the racetrack at the school. This involved printing their physical prototypes, racing them, then analyzing the high-speed footage of the car afterward in order to more accurately evaluate its dynamic properties. In the beginning, it was just a whole lot of real-life testing. When the team arrived at more accurate prototypes, meaning real cars at real scale, they then printed them iteratively.

“At this point we really did use a lot of CFD simulations in order to understand what we wanted out of those prototypes, and to improve them from one test day to the next,” says Rauh. “So, there were a lot of iterations before settling on a few prototypes and moving into the final optimization of our design. The next big stage involved simulation, which is our final optimization step. This involved a lot of hours, running a lot of CFD iterations to get a perfect result — they had to be the best cars we’ve ever made.”

Of particular interest to Team Sonic Boom was accurate assessment of the impact of aerodynamics on their design. Having all of the visualization tools provided by Ansys at their disposal helped the team to really understand the impact of drag and wind noise, and undesired lift forces and other causes of instability at high speeds. They initially used simulation to examine and reduce drag force, focusing on areas where they could really improve, specifically, areas of high static pressure, turbulence, and low-pressure. Doing a thorough track analysis using simulation enabled component optimization contributing to an overall design development plan around the difficulties caused by launch behavior of the car, for example.

CFD simulation of front section of the car

“When we analyzed the car, we saw that there was a tipping moment caused by the center of gravity being too far to the front,” says Wolf. “And then we looked at dynamic stability on track. There’s also the friction in the bearings and all these other scientific considerations that we have to think about when working on our design. With access to Ansys simulation software, we were able to quickly identify and address them all.”

Using Ansys software, the team could also export the velocity planes (as they relate to speed and direction) as pictures and then reload them into CAD software to adjust vehicle contours using a single PNG file. They could then visualize how the aerodynamics really worked in a specific plane and easily adjust shapes on the car directly.

Big Dreams Fuel Engineering Aspirations in Formula One Racing

Before graduating and going their separate ways, Team Sonic Boom spent an average of 40 to 60 hours a week preparing for their final, global competition together. Sleepless nights and suppers waiting outside bedroom doors were the norm, as were online communications and collaborations involving simulation software — without complaint.

Over the years, all of this hard work and teamwork did pay off. Team Sonic Boom won first place at the Bavarian Regionals four years in a row, from 2017 to 2020. Plus, they enjoyed a string of wins at the German Championships leading to a first-place victory in 2020, and qualification for the 2022 World Finals. At this year’s event, Sonic Boom placed fourth in the overall team ranking, and won the award for the best verbal presentation. They also won the Knockout Race — a thrilling elimination event featuring the fastest 16 cars of the competition.

Sonic Boom celebrating their Knockout Win, from left to right: Florian, Lukas, Jannis, Jakob, Anas, and Adrian.

Some of the best lessons for Team Sonic Boom came from working through the challenges of learning Ansys simulation, then applying that knowledge to solve large automotive design challenges with the help of some of the biggest engineers in professional racing. For many team members, F1 STEM competitions gave them the confidence to pursue dreams in engineering that extend well beyond high school.

“Team Sonic Boom is very aware of Ansys’ connection with Oracle Red Bull Racing,” says Izaaryene. “What really encouraged us was the chance to possibly work in an engineering capacity for Formula One in the future. After years of competing, most of our team members are really keen on getting picked up by Formula One and experiencing how it is to be an engineer at such a high level competing against other teams in real life. That would be something that would interest us a lot.”

Visit our Student Teams page to learn more about student team sponsorship here at Ansys.