-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

May 15, 2023

Developing a Software Framework to Design and Optimize Materials

What if you could improve a fan blade design by adapting a material property at different locations along the blade, extending its maintenance interval? Or enable researchers to test virtual prototypes of materials to predict their performance, saving time and resources?

The idea of integrating computational models and experiments to design and optimize materials is not new but has been limited by the maturity of the technology available in areas such as data management, software interoperability, and workflow automation [NASA Vision 2040: A Roadmap for Integrated Modeling of Materials and Systems]. This approach is defined as ICME, integrated computational materials engineering, which combines techniques from materials science, chemistry, physics, engineering, and software to create integrated and executable materials modeling workflows to understand mechanisms and behavior at different length and timescales.

Where Ansys Simulation Meets ICME

As a leader in engineering simulation, Ansys plays a key role in the development of software tools to enable ICME. It gives engineers the ability to model the structure of materials to predict their properties — for example, thermal-mechanical properties under different operating conditions. This is useful in simulating the behavior of complex materials like alloys or composites more accurately.

A few examples of these capabilities at Ansys:

- Material design for materials with complex microstructural features, composites, meta-materials and more.

- Multiscale workflow automation and orchestration.

- Management of materials and process information.

- Automated optimization, sensitivity, and robustness analysis.

Ansys ICME related tools extend beyond the examples shared above — and in combination with the different Ansys physics solvers which include micro-to-continuum scale models, and the ability to connect to third-party modeling tools — the applications that such a framework can reach is extensive.

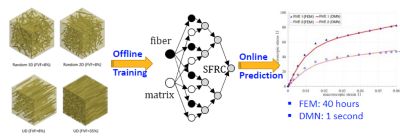

Use of a deep material network to accelerate property prediction.

Building Software Bridges Across Multidisciplinary Fields

ICME is, by nature, a broad and multidisciplinary field, with the materials scientist as the focal point. However, the average simulation analyst or engineer is not an ICME expert. One of the most cited success stories for ICME needed eight organizations, 25 people, and five years to achieve a return on investment (ROI) of 1:7, i.e. investment of one for a return of seven.

So, the challenge for implementing and using ICME across engineering businesses lies in creating a software framework that enables the ICME expert to:

- Build their workflows efficiently and with known uncertainty.

- Deploy their workflows to enable non-experts to easily select and trigger preconfigured ICME workflows.

Ansys have been active in finding and developing effective ways to tackle this challenge and have developed a framework proof of concept to enable the multidisciplinary collaboration and contribution needed for effective ICME. The current software tool configuration is being used to validate and test the idea against realistic use cases with early adopters in research projects, and finally to narrow down requirements.

Ansys ICME prototype

A Framework for the Future

What could this mean for the future? The proof of concept has been implemented to explore just how an ICME software framework might impact materials modeling adoption and success in manufacturing enterprises. So far, a variety of workflows have been implemented. These include:

- Designing and optimizing various hybrid and composite materials using the Ansys Material Designer tool in Ansys Mechanical.

- Predicting homogenized material properties from representative volume elements (RVEs) and grain properties using a crystal plasticity method implemented in Mechanical.

- Predicting and calibrating foam tensile properties using Ansys LS-DYNA.

- Predicting and calibrating kinetic parameters in a catalytic reactor using a custom model in Ansys Fluent.

- Predicting a relaxed molecular structure for organic electronic devices based on molecular dynamics simulations using third party solvers.

- Estimating effective laminate properties, residual stresses, and deformations based on basic laminate theory tools using the public platform nanoHUB.

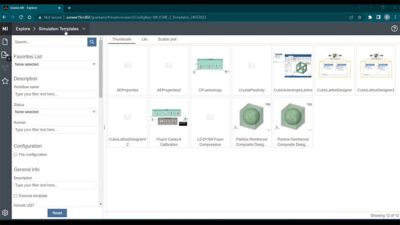

Simulation templates available within Ansys Granta MI

Ansys will continue to improve ICME tools and framework solutions with the vision that ICME will contribute to the significant reduction of trial-and-error experimentation approaches to materials development. Ansys has been active in finding and developing effective ways to tackle this challenge and have developed a framework proof of concept to enable the multidisciplinary collaboration and contribution needed for effective ICME. The current software tool configuration is being used to validate and test the idea against realistic use cases with early adopters in research projects, and finally to narrow down requirements. The outcome will be presented at the NAFEMS Worldwide Congress 2023 in mid-May.