-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

August 18, 2021

Beyond the Black Box: Gain Insights from Differential Vias with Optimization

There are many parameters that affect the design of vias – the critical interconnects between layers of printed circuit boards (PCBs) – and any one of them could lead to subpar performance or manufacturing challenges. Optimization algorithms can run through as many designs as needed to find the designs that meet certain optimization goals, but this “black box” approach doesn’t let you see which parameters are most important to via design, so it’s difficult to perform a cost tradeoff analysis or wring the most performance from the design. With Ansys HFSS 3D Layout and Ansys optiSLang, you can understand which parameters most affect the output of the design so you can improve it.

In the “Differential Via Optimization with Ansys HFSS 3D Layout and Ansys optiSLang” webinar, you’ll learn how to gain the most insight into a differential via design to optimize its performance and to study how manufacturing tolerances impact manufacturing yields.

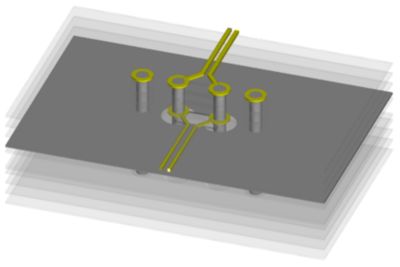

HFSS 3D Layout is geared toward PCB-like geometries where we can use our HFSS solver to analyze these structures. Any time we have layered geometries we find in a PCB, package or chip, we can use HFSS 3D layout. It is optimized for interacting with layered geometries.

Ansys optiSLang combines and optimizes data to improve designs

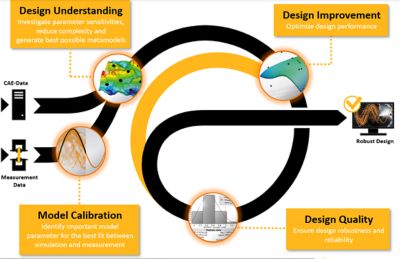

Ansys optiSLang is not just an optimization tool, though it does enable you use many different algorithms to optimize a design. At its core is variational analysis. If you give a parametrized simulation to optiSLang, it can control the input parameters and analyze their impact on the outputs of that simulation. Because optiSLang is software agnostic, you can take the output of one solver and use it as the input of another solver.

Optimization Demonstration Provides Design Insights

In the on-demand webinar, I walk you through an optimization of a via in an 18-layer PCB with FR4 substrates. The via is designed to connect coupled microstrips on layer 1 to coupled strip lines on layer 7. The optimization goals are simple for demonstration purposes:

- The differential return loss (SDD11) from 0 to 40 GHz must be minimized

- The maximum SDD11 must be better than -13 dB

- The initial design maximum SDD11 is -5.15 dB

At a high level, this optimization approach focuses on gaining insight into the design by performing a sensitivity analysis to explore the design space, which ensures we are locating the global optimum, not a local one; determines what parameters have the most impact on the differential return loss; and enables you to perform optimizations based on a metamodel. You can decide to move on or, if time is available and every bit of performance should be squeezed out of the design, a direct optimization can be run as efficiently as possible using the knowledge gained from the sensitivity analysis.

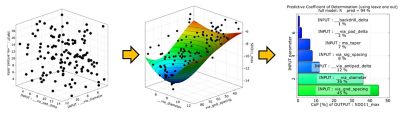

The sensitivity analysis in Ansys optiSLang creates a design of experiments and has Ansys HFSS 3D Layout evaluate those designs.

Then optiSLang fits a metamodel of optimal prognosis (MOP) to the evaluated results. Using MOP, optiSLang can quickly study the design space without requiring HFSS to evaluate additional designs of interest.

Finally, optiSLang determines the sensitivity of the device response to the input parameters to determine where small changes will cause the largest change in the response, and which parameters have minimal impact.

With the sensitivity analysis, optiSLang looks at ranges of input parameters and creates a design of experiments (DoE) that HFSS 3D Layout evaluates. Ansys optiSLang then fits a metamodel of optimal prognosis (MOP), which it uses to quickly study a design without requiring HFSS to evaluate additional designs of interest.

The MOP is a mathematical model that can be used in place of an explicit simulation to quickly predict the output of a design. optiSLang contains many different metamodels that it fits to the model using a subset of data. You can see how it compares to the actual response from the simulation to get a coefficient of prognosis to assess which metamodel does the best job of predicting data that we have not explicitly solved for yet.

It’s an adaptive approach that continuously improves the accuracy of the metamodel, while also finding better and better designs. The adaptive MOP approach is perfect tradeoff between gaining insight into the design and having the most robsut approach to optimizing the design.

The robustness analysis shows what percentage of manufactured devices fails a specified design requirement. This analysis will also indicate which of the manufacturing tolerances must be improved to increase the yield.

I hope that’s enough to whet your appetite. To explore the details of how to gain more insights from optimization, check out the “Differential Via Optimization with Ansys HFSS 3D Layout and Ansys optiSLang” webinar.