-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

Ansys Blog

November 3, 2020

3 Ways to Improve Sound Engineering

We rely on sound without even thinking about it. The solid thud of a car door, the rumble of a motorcycle or the tone of a smartphone can subconsciously affect how we feel about a product’s quality.

Whether a product’s sound is a core part of its functionality or a side effect of its use, you need to know the acoustic qualities of your designs before they’re manufactured.

The Problem with Physical Prototyping

Sound is an important part of the customer experience, but it sometimes gets neglected. Unless sound is seen as integral to the functionality of the product, it might be pushed to the back burner as deadlines approach and prototyping costs rise.

With traditional engineering methods, it’s often late in the product design and development process when a sound issue is noticed. At the 11th hour, difficult decisions have to be made: Do you release the product or completely overhaul the design from step one? Either way, time, money and the company’s reputation for quality are at risk.

Subjective jury evaluations

provide a deeper understanding

of the way potential customers

react to and appreciate sounds.

Listen Early and Often with Simulated Sound

Ansys Sound enables you to listen to a simulation of your products’ sounds, based on a virtual prototype.

The sound quality can be assessed and improved at the very earliest stages of development. Whether the sounds are directly related to functionality, like a doorbell, or a side effect of operation ― such as the noise produced by a golf club, jet engine or a hairdryer ― Ansys Sound can help optimize the acoustic result.

A recent white paper, “Amplifying the Benefits of Acoustic Simulation,” explains how you can create products with sound in mind, easily and early on in the design stage, when costs and risks are low.

Three Ways to Design with Sound in Mind

Based on closed-loop feedback from Ansys Sound, virtual product models can be optimized for both core functional performance and the resulting acoustic effects, creating a universally positive customer experience. Below are just three ways from the white paper that you can use Ansys Sound.

- Isolate noise sources to understand their impact on overall sound quality. Instead of waiting for the physical prototyping stage, the correction of any unwanted noise can be accomplished as products are being virtually modeled. You don’t have to guess at the sources of unwanted noise; you can accurately see where negative acoustic effects are originating in the 3D product model.

- Define acceptability ranges based on human perception criteria and psychoacoustics. For some products, acceptable acoustic ranges are defined by industry and government regulators. But, for the majority of products, acceptable ranges are more qualitative, based on listener perceptions. Ansys Sound can reveal these qualitative preferences and help optimize sounds for the real-world user experience.

- Reshape the sound of products, rather than simply reducing their loudness. Just as products have a design aesthetic that reinforces their brand image and attracts consumers, products can also have a uniquely attractive sound signature that draws consumers to the brand. Instead of just making products quieter, Ansys Sound can help proactively shape their sounds into a pleasing blend based on the human auditory experience. Once the target sound and the sound quality criteria are defined, the connection of Ansys Sound to Ansys simulation tools, such as Ansys Mechanical and Ansys Fluent, allows iterative process to have virtual prototype with sound closed or matching the target. Then, you can manufacture the real prototype with the right sound.

Integrate Sound Engineering into the Development Process

You can use Ansys Sound on its own to gain high-quality acoustic results, but for the greatest benefits, pair it with other Ansys simulation tools. Within the shared Ansys platform, it’s simple to bring simulations results from Mechanical or Fluent into Ansys Sound.

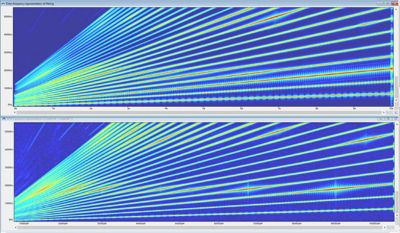

These two images produced by Ansys Sound graphically

demonstrate the acoustic effects of a car’s engine. In the bottom

image, the sound has been “tuned” by improvements made to the

virtual engine model following an acoustic analysis.

With an integrated workflow, there’s no sound guesswork during the design process because you can test auditory results at the beginning of a project and easily make any redesigns within Mechanical or Fluent until the desired sound outcome is reached. Late-stage sound surprises are eliminated when you simulate for sound, just like you simulate for functionality.

A Sound Engineering Solution that Resonates with Product Developers

Product engineers are faced with many challenges during design and production. Sound can be an overlooked aspect with potentially potent consequences. Negative customer reviews of how a product sounds can make or break a product. Regulations that cover sound can derail new product introductions. A company’s reputation for quality can be hurt if their product sounds worse than the competition.

Ansys Sound, together with Mechanical and Fluent, offers the solution for discovering the best auditory results. Simulated sound provides the opportunity to authentically create product sounds in any stage of design development. Modeling sound ensures a positive consumer experience every time.

Discover more about Ansys Sound by downloading the “Amplifying the Benefits of Acoustic Simulation” white paper.