-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Take Simulation Underground

Byron Stanley, CTO, WaveSense, Inc., Somerville, U.S.A. and Ansys Advantage Staff

While it would not seem to matter what is under the road an autonomous car is driving on, WaveSense engineers are using Ansys HFSS electromagnetic solutions to develop a system to map the underground features of roads for precise location verification in all conditions.

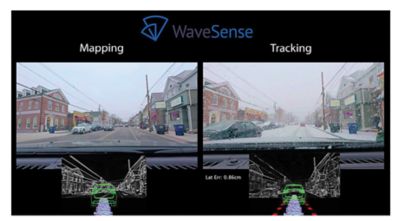

In the race to create the technologies that will make autonomous driving a reality, most engineers have focused on getting sensors to detect, interpret and react to objects from the road up. To solve one of the toughest challenges — keeping the vehicle in its driving lane when the painted lane markers are in poor condition or are obscured by snow, fog or rain — engineers at WaveSense are pointing their radar devices straight down. The radar positioning system is also being actively used in parking garages, on overpasses and in parking lots.

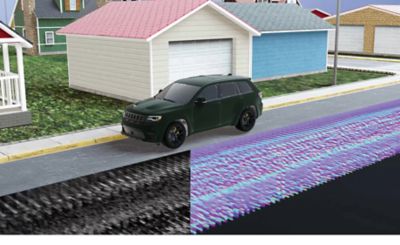

The idea is to use ground penetrating radar (GPR) scanning at approximately 100 times per second and reaching 10 feet underground to detect the unique radar signature of subsurface objects like different types of soil, rocks, pipes, rebar, tree roots, etc. The resulting radar “fingerprints” are collected to create a radar map of a particular stretch of road. With this radar map stored in an onboard computer, an autonomous vehicle equipped with GPR technology can compare real-time radar signals to the map to pinpoint its position within a tolerance of 1 inch — plenty of resolution to determine whether it is drifting out of its lane.

As a vehicle is driving, it localizes by scanning the subsurface and instantly matching the scans to a prior map.

The concept was developed by researchers at MIT’s Lincoln Laboratory around 2009. GPR was first deployed on automated 9-ton military vehicles in Afghanistan in 2013, where roads are often not clearly defined, and where drifting off the standard path might prove fatal. In 2017, MIT researchers created the spinoff company WaveSense, Inc., to design GPR units suitable for passenger vehicles and trucks for the consumer market. The WaveSense team is using Ansys HFSS to optimize radar performance while reducing costs and getting the product to market faster. The company gained access to HFSS as a member of the Ansys Startup Program.

The company measures and records reflections from underground pipes, roots, rocks and soil, and constantly updates WaveSense’s database of maps.

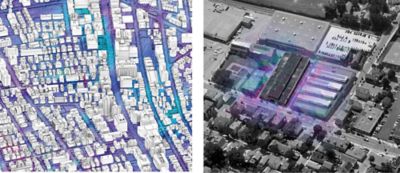

The Logistics of Mapping the Roads of the World

Though it might seem challenging to generate underground data maps for enough of the world’s roads for general use, WaveSense offers a solid approach. First, they are starting by mapping the highest value areas — large ride-hailing markets, major parking structures and lots, and the biggest freight routes. Maps of these areas produce value from the start without offering comprehensive coverage of every street or highway in the world. Once the highest value areas are mapped, they will then spread out to the smaller traffic arteries. And, because the subsurface structure is generally stable, much of the map will not need updating for years or decades.

WaveSense does not plan to do all the mapping themselves. Besides its own fleet of vehicles, the company will work with partners who already have large fleets of trucks and cars on the road. In a nod to the gig economy, WaveSense also is in discussions to team up with ride-hailing services and eventually mass-produced consumer vehicles equipped with map data update systems. There are a lot of ways to fill out the map, and WaveSense plans to take advantage of all of them.

Engineering and Education Challenges

As a proof-of-principle device, the first-generation GPR units for military purposes were as wide as the vehicle itself. WaveSense is now engineering the production design — with a bill of materials less than $100 — to fit into a 1-by-2-foot-by-1-inch footprint for installation underneath commercial automobiles and trucks. Because automakers are generally concerned about weight and space, WaveSense must miniaturize and optimize the radar antenna and associated electronics without sacrificing resolution or accuracy. HFSS enables them to virtually prototype various configurations of geometry parametrically and use optimization routines to help find ideal geometry that delivers acceptable performance.

Understanding radar gain patterns in various environments is another challenge. HFSS is helping the engineers understand how radar patterns are affected by the nearby mass of metal — the car or truck body — and the nature of the roadway materials and underground features being

Simulation Below the Surface

The WaveSense GPR system emits signals in the UHF to VHF frequency range. At these wavelengths, a great deal of character is visible from radar reflecting from underground features. Any changes in the electromagnetic properties of the road produce a unique fingerprint that is essential for creating the radar maps that make this technology viable. Though it seems like the onboard radar map would require significant data storage space, it only takes up a small fraction of the data space required by other systems in an automated vehicle.

Using simulation, WaveSense engineers are able to reach their design points in a timely manner and at a more reasonable cost.

The radar positioning system is being actively used in parking garages, on overpasses and in parking lots.

Using HFSS, the engineers simulate various radar antenna sizes and configurations, along with the shape of the radar transmission energy and how it disperses into the environment. This is used to determine performance in a range of different physical environments and ground conditions. To date, they have run thousands of HFSS simulations using automated meshing with subwavelength features, including parameter sweeps, ground and vehicle effects studies, and infrastructure and material studies. Depending on the complexity, simulations take from hours to days on a 32-core server. Ansys engineering simulation technology has helped WaveSense develop a better understanding of optimal design parameters, materials and overall performance. It saves significant time and effort to simulate before building each revision of a design. Using simulation, WaveSense engineers are able to reach their design points in a timely manner and at a more reasonable cost than by building and testing physical prototypes.

WaveSense is mapping the highest value areas — large ride-hailing markets, major parking structures and lots, and the biggest freight routes — first.

Using Gpr in Sunny Weather

GPR will always provide significant value in bad weather, when lane markers are not visible to the cameras mounted on autonomous vehicles. But even in fair weather, the fact is that an above-ground visual camera, lidar or other sensor will eventually fail, so having an independent GPR unit is a good idea. Fusing GPR with more standard autonomous sensors leads to substantially lower overall failure rates for autonomous systems.

In any case — rain, snow, fog or shine — WaveSense continues to use Ansys HFSS to optimize ground penetrating radar technology to create maps that most of us had never thought of — maps of the underside of the roads we drive on.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.