Analysis of a 3D Printed Heat Exchanger Using Ansys Discovery Software

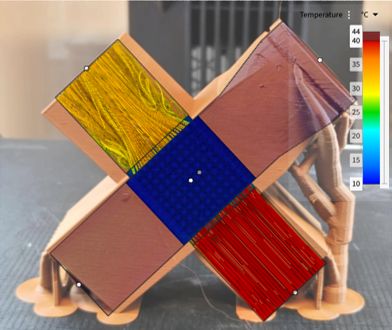

This case study explores the design, testing, and simulation of a 3D-printed cross-shaped heat exchanger using Ansys Discovery™ 3D product simulation software. It provides a comprehensive overview of heat transfer principles, focusing on convection and conduction within a copper-filled PLA structure. The resource details experimental setup and procedures for measuring inlet/outlet temperatures and flow rates, followed by computational fluid dynamics (CFD) simulations to visualize conjugate heat transfer and flow behaviour. It emphasizes the importance of accurate boundary conditions, material property estimation, and mesh refinement for reliable simulation results. Additionally, the study identifies potential sources of discrepancy—such as porosity, turbulence, and geometric tolerances—and discusses strategies for improving design efficiency. This resource serves as an experiential learning tool for students and engineers, bridging theoretical concepts with practical applications in thermal-fluid system design and optimization.

This case study uses results from a workshop run by the authors at the IDEAs Clinic at the University of Waterloo.

Learning Outcomes

- Apply principles of heat transfer and fluid flow in heat exchanger design.

- Analyze conjugate heat transfer using simulation and experimental data.

- Evaluate thermodynamic efficiency and pressure drop in thermal-fluid systems.

Applicable Courses for Use

- Heat Transfer

- Applied Thermodynamics

- Fluid Mechanics

Downloadable Content

- Case Study Report

- CAD File

Related Resources

Heat Transfer with Ansys Discovery | Education Resources