The 2025 R2 release features enhanced physics-based solvers, streamlined workflows, and new AI-powered tools, all designed to accelerate simulations and simplify adoption. With Ansys digital accelerators, teams can scale simulations, explore more innovative design possibilities, and make intelligent product decisions earlier.

Harness Physics-based AI for Intuitive Simulations

Ansys 2025 R2 introduces Ansys Engineering Copilot — a secure, robust, and reliable virtual assistant built on decades of Ansys technical expertise. It delivers powerful, AI-driven assistance directly within native Ansys products, including Ansys Mechanical, Ansys Discovery, Ansys Fluent, Ansys HFSS, Ansys Electronics Desktop (AEDT), Ansys Lumerical Products, Ansys Scade One, Ansys Speos, and Ansys optiSLang.

Maximize Results Through Improved Data Handling and Automation

This release elevates digital engineering with advanced simulation process and data management (SPDM) technology, enhanced model-based systems engineering (MBSE) tools, and streamlined workflow automation for efficient simulation data handling. Expanded Python compatibility and an open engineering framework make simulations more accessible, encouraging broader adoption and helping engineers tackle challenges effectively.

Drive Digital Change With Cloud-based Physics

By utilizing cloud technology, high-performance computing (HPC), and GPU-optimized infrastructure, we enhance physics computations and simulations. These advancements enable quicker and more scalable simulations, allowing customers to explore a broader range of design options. With expanded web-based capabilities, engineers can easily access tools, streamline workflows, and advance product development beyond traditional desktop limits.

Product Highlights

Ansys 2025 R2 introduces AI capabilities across the portfolio to automatically create, validate, and optimize high-fidelity simulations — speeding up model creation, reducing manual effort, and mitigating human error. By providing real-time, smart functionality that frees users to focus on high-priority tasks, Ansys technology lays the groundwork for autonomous AI, helping customers drive innovation forward at every step.

3D Design

Ansys Discovery 2025 R2 brings robust new simulation, meshing, and AI-driven support capabilities to accelerate early design validation. Key highlights include Random Vibration for statistical analysis of dynamic loads, enhanced meshing with the body of influence and sharp edge capture for fluids, and smarter defaults for structural simulations. The release also debuts Ansys Engineering Copilot, an AI-powered assistant that provides real-time, in-product guidance to help users troubleshoot and learn more efficiently.

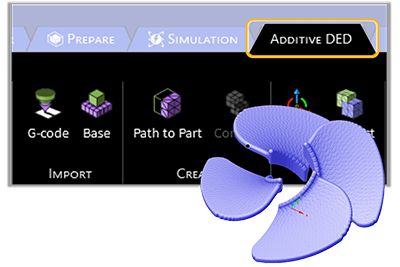

Additive

Ansys Additive 2025 R2 delivers key innovations to streamline additive manufacturing workflows and improve part accuracy. With more innovative simulation capabilities and expanded interoperability, engineers can reduce trial-and-error cycles and accelerate time to production. Whether simulating thermal effects, calibrating strain models, or managing process parameters, this release enhances control, efficiency, and confidence.

AI

Ansys SimAI 2025R2 introduces significant enhancements to improve user experience, streamline model development, and refine data handling. Key features include the "predict as learned" surface post-processing, the return of the Surface Evolution tool, and clearer Model Evaluation Reports. Users benefit from improved dataset management, real-time updates, a centralized error view, and enhanced UI elements, including accessible documentation, member counts, and upload notifications, all of which contribute to a more efficient workflow and greater transparency.

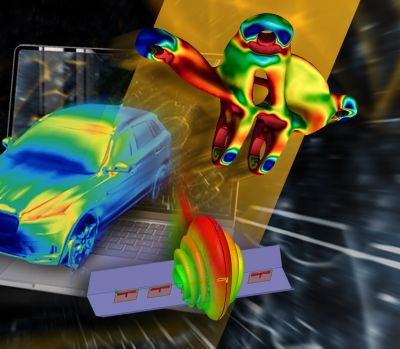

Autonomous Vehicle Simulation

The 2025 R2 AVxcelerate Sensors upgrades enhance ADAS and autonomous vehicle technology with advanced camera and radar sensors for improved accuracy and low-latency communication. These upgrades also include customizable testing conditions and streamlined scenario-based testing workflows. New analysis tools and faster data processing enable efficient decision-making. At the same time, support for ASAM OpenSCENARIO 1.3 ensures compatibility and interoperability across various simulation platforms, thereby optimizing performance and safety in complex driving scenarios.

Connect

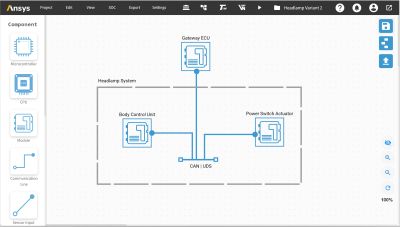

Our 2025 R2 release enhances Model-Based Systems Engineering (MBSE) with the new System Architecture Modeler Enterprise, integrating workflows for software prototyping, safety, and cybersecurity. The release enhances data management through the Ansys Granta product collection, offering improved material assignments and enhanced tool integration. Ansys Minerva features a refined UI for simulation management, while optiSLang 2025 R2 connects with Ansys SimAI for streamlined AI model training, enabling non-experts to perform basic optimization tasks within Ansys solvers.

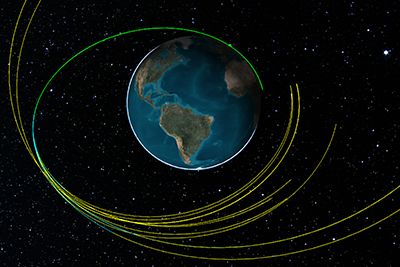

Digital Missions Engineering

The 2025 R2 release of Digital Mission Engineering (DME) enhances customer confidence with strategic innovations that improve integration and control. The integration of Ansys STK and ODTK streamlines satellite design and operations, accelerating workflows during the mission lifecycle. Ansys STK Aviator introduces flight control-based trajectory modeling, a crucial feature for autonomous systems. These advancements in PySTK expand access to analytical tools, facilitating collaboration between engineering teams and accelerating development cycles through integrated modeling environments.

Digital Twin

Digital twins transform the way engineers simulate, predict, and optimize product performance, driving faster innovation and more informed decisions. This webinar highlights the latest advancements in analytics, automation, and modeling, including hybrid analytics with multi-output Gaussian process fusion, a new twin-deployment web app, and enhanced ROM creation tools. Discover key solver and model library updates that enhance usability and performance across various applications.

Electronics

This release introduces significant enhancements in workflow and design accuracy for electric machines, featuring axial flux machine optimization and pre-stressed mechanical integrity calculations. Key updates include a streamlined compiled import process, GPU acceleration for thermal integrity analysis, and improvements in antenna array postprocessing. It also offers far-field EMI/EMC simulations for PCBs and advanced radar output capabilities, collectively enhancing computational performance and empowering engineers to address complex electromagnetic and thermal challenges with greater efficiency and precision.

Embedded Software

The 2025 R2 release provides significant advancements across Ansys SCADE and Scade One to accelerate development and support certification. SCADE offers enhanced ARINC 661 support, improved error reporting, debug traces, and better integration between SCADE Display and Scade One. Certification updates include compliance improvements for DO-178C, ISO 26262, IEC 61508, and EN 50128. Scade One continues to evolve with the Ansys Engineering Copilot, integrating AnsysGPT and access to technical content within the IDE, plus Python wrapper support, operator-level debugging, improved CI/CD integration, and enhanced performance for safety-critical code generation.

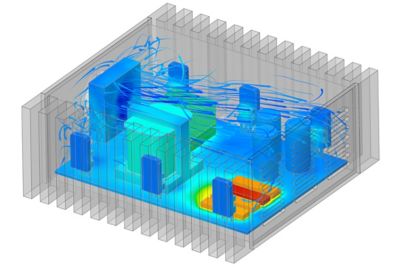

Fluids

Ansys Fluids 2025 R2 introduces key enhancements to boost performance and productivity, including a more advanced Fluent GPU Solver with robust models for various applications. It features the integration of Ansys Engineering Copilot into the Fluent Desktop Interface and GPU solver into the Fluent Web Interface. Additionally, Ansys FreeFlow, a meshless SPH solver, has been fully released alongside improvements to Thermal Desktop, Rocky, and CFX, which include new integrations, usability enhancements, and refined physics.

Materials

Ansys Granta 2025 R2 enhances connections across the simulation digital thread, improving reliability and traceability. Key updates include better material assignments from CAD to CAE, advanced selection tools, and sustainability-focused data. The release features new materials data for tapes, adhesives, and a database of commercially available composite materials, along with datasets for metal forming applications. These enhancements empower engineers to make informed, data-driven decisions with greater ease and efficiency.

Optics

The Ansys Optics 2025 R2 release strengthens optical and photonic system design with new tools for improved speed and accuracy. Key updates include the visual sequence builder in Ansys Zemax OpticStudio for complex ray paths, faster metalens simulations, and seamless exports to Ansys Speos, which now features cloud burst computing and glTF import. Ansys Lumerical introduces GPU-accelerated simulations, empowering engineers to innovate in imaging, AR/VR, sensing, and communications with greater confidence and efficiency.

Safety Analysis

We are thrilled to introduce Ansys Medini Cybersecurity SE, a cutting-edge model-based tool designed to elevate your analysis skills. It provides a holistic approach to establish context, identify assets, detect threats, build attack trees, assess risks, and devise mitigation strategies. As an entirely web-based solution, it seamlessly integrates architectural and functional design models with advanced cybersecurity practices.

Semiconductors

Ansys 2025 R2 enhances semiconductor design with new technologies and partnerships. It introduces an AI co-pilot in RedHawk-SC to streamline intelligent design workflows. The PowerX solution caters to the demands of power device designs like PMICs for inverters and EVs. PathFinder-SC has received full signoff certification from TSMC for multi-die ESD analysis. Additionally, TSMC and Ansys developed a multiphysics flow for co-packaged optics, improving accuracy and usability within TSMC’s COUPE architecture.

Structures

The 2025 R2 release amplifies the structures portfolio with new features for engineers. Mechanical introduces Ansys Engineering Copilot, an AI-driven design tool, enhanced mesh workflows, and advanced structural optimization. LS-DYNA expands material models and adds battery simulation capabilities. Forming sees upgrades in analysis and material libraries, while Sherlock enhances solder fatigue modeling and integrates thermal mapping workflows. The Sound module features new psychoacoustics tools and a Python library, while Motion offers extensive enhancements to drivetrain performance and modeling.