領先的驅動器製造商推動數位化,以簡化工作流程並支援永續發展。

越來越多的製造商正朝向數位化邁進,而且他們有充分的理由這麼做。McKinsey & Co. 的報告指出,以先進資料與分析、人工智慧與機器學習 (AI/ML) 及其他技術為基礎的解決方案,若能成功整合,可將機器停機時間減少 30% 至 50%,產出率提高 10% 至 30%,勞動力生產力提高 15% 至 30%,並將預測準確度提升 85%。

Danfoss Drives 是能源效率領導品牌 Danfoss 的子公司,利用 Ansys 模擬解決方案和工業 5.0 技術,提高其經典產品交流 (AC) 驅動器的生產效率。營運效率的優勢也延伸至環境層面,能耗更低、機械排放更少。

透過利用 Ansys 多物理模擬解決方案 (包括 AI/ML 和以 Python 為基礎的工具) 建立模擬應用程式,該公司實現了整個團隊的模擬普及化,並簡化了設計和開發流程。因此,Danfoss Drives 能減少實體原型製作數量,降低成本並節省時間的同時,滿足客戶需求並支援永續發展。

透過模擬普及化提高效率

Danfoss Drives 的 iC7-Automation 是一款低電壓驅動器,專為各種恆定功率/扭矩應用而設計。

AC 驅動器可控制電動馬達的轉速以符合負載需求,廣泛應用於從物料搬運與加工到食品與飲料等多種產業。它們可以強化製程控制,減少能源使用,減輕馬達控制應用的機械應力,並最佳化各類依賴電動馬達的應用運作。

Danfoss Drives 已導入 Ansys 解決方案逾 10 年。該團隊的一些首選多物理模擬工具包括:

Danfoss Drives 的 VLT® Decentral Drive FCD 302 無需使用占用空間的控制櫃,非常適用於食品、飲料和物料搬運行業等需要使用大量驅動器的廣泛分佈式應用。

最近,Danfoss Drives 的電力電子產品和驅動部門在其工作流程中採用了更多 Ansys 解決方案,包括 Ansys 軟體專用的 PyAnsys Pythonic 存取工具。

PyAnsys 套件 (包括 PyFluent工具、PyAEDT工具和 PyEDB 工具) 可讓工程師為各種程度的使用者編寫簡單易用的模擬應用程式。

Danfoss Drives 虛擬設計、測試與最佳化主管 Michael Laursen 表示:「我們希望讓所有人,例如非模擬專家的設計工程師,都能根據模擬結果做出決策。」「因此,我們正在建立為特定模擬量身打造的模擬應用程式,供非模擬專家的團隊成員使用。」

應用程式是自動化的,因此模擬會在背景中執行。使用者可以輕鬆登入網頁並選擇想要使用的應用程式。

利用 AI 洞察最大化模擬能力

該團隊也正在探索 Ansys 的 AI 解決方案,包括 AnsysGPT AI 支援虛擬助理,以及用於知識擷取和驗證的 Ansys SimAI 雲端 AI 平台。

Laursen 表示:「這是我們數位化旅程的一部分,我們目前的研發重點放在知識擷取代理程式上,我們正在研究運用更多代理架構來將多種代理程式整合在一起。」「從長遠來看,我們的願景是,研發一個具有模擬專家功能的代理程式,讓我們可以從虛擬環境連接實體環境,並藉此評估我們是否在尋找這些解決方案的正確道路上。」

AnsysGPT 助手使用 Ansys 資料進行訓練,可提供全天候 24 小時的技術支援,並從可靠的 Ansys 資源中生成量身打造的專屬回應,這些資源包括 Ansys 創新課程、技術文件、部落格文章和操作方法影片。

SimAI 是一款與物理無關的雲端原生平台,您可以在此平台上使用之前從 Ansys 產品或其他來源生成的資料來訓練 AI 模型,並在幾分鐘內完成新設計的效能評估。軟體即服務 (SaaS) 應用程式結合了 Ansys 模擬的預測準確度與透過雲端之生成式 AI 的速度,透過雲端運算將計算密集型專案的整體設計流程效能提升 10 到 100 倍。

基本上,Ansys SimAI 工作流程包含三個簡單的步驟:上傳資料、訓練模型及預測。

該團隊在最近的試行專案中,以兩種使用案例對此工具進行了效能和準確度評估。

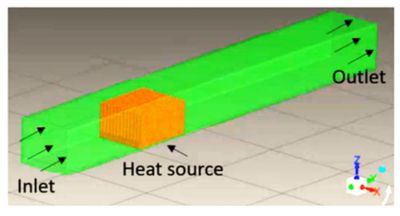

第一個使用案例是散熱片。該團隊使用 Fluent 軟體和 Ansys optiSLang 流程整合與設計最佳化軟體,在 SimAI 平台中使用約 86 種不同的幾何變化和六個幾何參數建立並訓練 AI 模型。其中包括散熱片寬度、散熱片長度、鰭片高度,基板厚度、鰭片厚度和鰭片數量。

Danfoss Drives 的電力電子產品和驅動部門在兩個使用案例 (包括散熱片) 中評估了SimAI 軟體。

SimAI 模型準確地預測出最高和平均溫度,最大相對誤差小於 0.6%。該模型可廣泛應用於新的幾何變化,並維持高預測準確度。

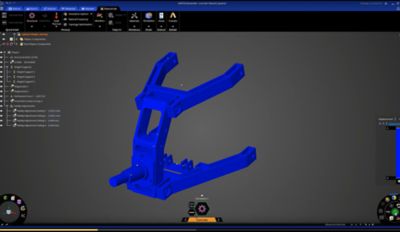

第二個使用案例是棧板落摔測試模擬。該團隊運用 Mechanical 軟體和 Ansys LS-DYNA 非線性動力結構模擬軟體,使用位移和應力場的現有模擬資料,在 SimAI 平台中建立並訓練 AI 模型。

SimAI 模型的結果與傳統求解器的結果趨近一致,尤其是平均和最大位移和應力值的結果,展現高度準確性,與先前模擬的偏差率通常小於 5%。此成果是一次成功的概念驗證,展示了 SimAI 工具如何加速模擬任務、降低成本,並能進行廣泛部署,即使是非專家使用者也能輕鬆完成部署。

在 Ansys Discovery 軟體中,您可以在數秒內評估多個設計想法,並分析材料,以找到最佳的結構配置。

利用虛擬環境

Laursen 和他的團隊在初期便整合模擬,以加速設計迭代。

他表示:「這就是關鍵所在──我們希望盡可能延長停留在虛擬環境和模擬環境中的時間,因為這樣就可以真正進行敏捷式的產品開發。」「如果一開始就在開發循環中放入真實的硬體,您便需要完成從訂購零件、等待零件,接著組裝零件,到前往實驗室進行測試的完整流程,這是一個非常冗長的開發循環和週期。在虛擬環境中,您沒有真實世界的各種限制,因此更容易進行更多設計迭代。」

Danfoss Drives 的客戶也看到數位工作流程的優勢。

Laursen 表示:「我們從客戶說那裡清楚聽到這樣的訊息,如果我們無法提供數位模型和未來技術方面的支援,我們就不再是具有價值的供應商。」

除了提升設計迭代速度和客戶滿意度之外,Danfoss Drives 的首要目標之一是減少實體原型的製作數量,這已帶來了可觀的成本節約效益。

「通常,我們會有四次原型設計迭代:一次概念原型,兩次詳細設計原型,以及一次原型的生產。」Laursen 表示。「透過 Ansys 模擬,我們能夠省去一次詳細設計原型迭代,這為我們節省了六到九個月的開發時間和大量金錢。時間非常重要,但早期原型製作的成本也相當高昂。」

Laursen 計劃擴充虛擬原型設計能力,團隊的最終目標是只有一個實體原型。

立即擁抱數位工作流程

Danfoss Drives 的 VLT® Midi Drive FC 280 為食品飲料、物料搬運與加工等產業的機械製造商提供精準且高效率的馬達控制。

造訪我們的 工業製程與設備模擬軟體解決方案頁面,瞭解 Ansys 如何支援您的業務及營運。

閱讀部落格「Danfoss Drives 運用模擬技術支持永續發展與數位轉型」,深入瞭解 Danfoss Drives 的數位化旅程。