Falls are a leading cause of death for construction workers globally, including in Europe and the U.S. In 2023, nearly half of all fatal falls, slips, and trips in the U.S. occurred in construction, according to the U.S. Bureau of Labor Statistics.

What if automation could minimize or even eliminate construction casualties caused by falls?

That’s the driving force behind KEWAZO, a robotics startup founded in 2018 at UnternehmerTUM, the center for innovation and business creation at the Technical University of Munich. With offices in Germany and the U.S., the startup set out to automate complex, unsafe, and physically demanding construction industry tasks.

To do this efficiently, KEWAZO used multiphysics simulation tools from Ansys, part of Synopsys, to develop LIFTBOT, a material lifting robot. With access to the software through the Ansys Startup Program and support from CADFEM Germany GmbH, an Ansys Apex Channel Partner, KEWAZO continues to integrate Ansys structural and multibody dynamics simulation to ensure equipment durability, shorten development cycles, and cut costs.

See the LIFTBOT in action.

Accelerate Development and Certification with Simulation

LIFTBOT is a fully wireless, battery-powered vertical lifting solution for transporting materials in large-scale operations at industrial plants or commercial sites. Transportation platforms, which can easily attach or detach from the LIFTBOT, accommodate different material sizes, shapes, and weights, such as scaffolding assembly parts, sandblasting equipment, insulation, paneling, mechanical work, and painting. The startup also customizes solutions with customers to address specific needs.

“Digitalization is the key to maintaining our rapid pace of development,” says Aleksandar Belberov, chief technology officer (CTO) at KEWAZO. “Every new component we engineer undergoes an iterative simulation cycle: We evaluate its performance in the system, optimize the design, and then reevaluate it to validate the improvements.”

LIFTBOT is a fully wireless, battery-powered vertical lifting solution for transporting materials in large-scale operations at industrial plants or commercial sites.

Due to such meticulous engineering, acceleration and efficiency were primary reasons for KEWAZO’s simulation integration.

“We started using simulation early on because we wanted to move fast,” says Edgar Blanco, a calculation and simulation engineer at KEWAZO. “With one calculation engineer supporting several mechanical designers across multiple projects, we can test and iterate quickly without having to build endless prototypes. That saves us time and cost, and as a startup — a hardware startup especially — we very early on accepted the mantra of doing more with less.”

Simulation has also played a key role in certification with regulatory groups such as TÜV, a German technical inspection association.

“For example, we used structural simulations as part of our certification process with TÜV,” Blanco says. “Because TÜV also works with Ansys software and accepts simulation results as reliable proof of structural soundness, it allows us to validate designs efficiently and with confidence as well as iterate based on their feedback.”

Designed for usability, LIFTBOT supports a broader adoption of automation and robotics in the construction and industrial equipment industries. It makes it easier for current workers to incorporate advanced technologies into their workflow while alleviating labor shortage concerns and skills gaps.

Just a handful of LIFTBOT’s features include:

- Maximum possible speed for a material hoist

- Quick setup in under 20 minutes and minimal training time of around an hour

- Agile and speedy deployment — the same robot can be moved across different projects and locations within minutes

- Autonomous operation — one battery charge lasts 10 hours, and the robot can be operated using a remote control

- Transparency of on-site activities via live operational data analytics, which enables customer awareness and supports troubleshooting

In addition, LIFTBOT is equipped for safety inside and out. It is designed with advanced safety architecture, including software and sensors, and isn’t dependent on additional anchoring or bracing. Simulation significantly contributes to this structural durability and reliability.

LIFTBOT operates autonomously using battery power, with one charge lasting 10 hours.

Increase Efficiency with Structural and Multibody Dynamics

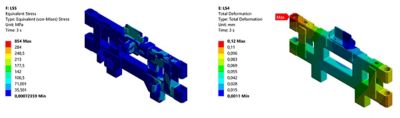

With CADFEM’s support, Belberov and team integrate Ansys Mechanical structural finite element analysis (FEA) software and Ansys Motion multibody dynamics simulation software.

Mechanical software is used to evaluate LIFTBOT’s system requirements, performance, and fatigue life, while Motion software is used to model LIFTBOT’s ability to endure realistic accelerations and force interactions during movement.

KEWAZO engineers use Ansys Mechanical structural finite element analysis (FEA) software to assess the LIFTBOT’s interface frame for stress and deformation.

“As a hardware startup, resources are often limited and have to be distributed with great care,” says Belberov. “Acquiring Ansys software early on also requires acquiring the necessary hardware and hiring a specialist for maximum effectiveness. The Ansys Startup Program and consequent affordable pricing have allowed us to offset some of these additional costs and be able to justify the resources spent.”

CADFEM introduced KEWAZO to the Ansys Startup Program and provides ongoing training and technical support, including instrumental guidance during product certification.

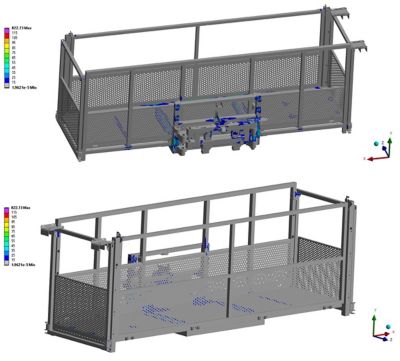

Although specific benefits vary from project to project, simulation, including FEA and fatigue analysis, has generally sped up development and cut costs. For example, in one development project for a small structural component, KEWAZO iterated the design in simulation for just around four months and only built one prototype. Additionally, simulation-driven design iteration resulted in 20% less manufacturing costs and 20% less total part weight.

“This efficient process [of iterative simulation cycles] accelerates our development timeline, empowers our mechanical engineers, and allows us to roll out incremental changes to both new and existing products,” says Belberov. “Our commitment to continuous improvement delivers lasting value to our customers.”

The KEWAZO team evaluates LIFTBOT’s general material transportation platforms for stress using Mechanical software.

Grow Your Business with Simulation

What’s next for LIFTBOT and KEWAZO? Expansion.

“We have built an excellent foundation in robotics, actively working on our artificial intelligence (AI) capabilities for near-future deployment, and have developed the foundational relationships with essential leaders in heavy industry,” says Belberov. “This positions us to become the go-to robotics company in the field, not only by expanding the LIFTBOT product portfolio, but by providing additional hardware and software solutions for material, equipment, and personnel transport on site.”

Whichever product comes next, simulation will play a role in its development as it continues to shape KEWAZO’s existing products.

“I already mentioned how Ansys simulation has helped us certify our first product, which has contributed greatly to our business growth,” says Belberov. “Since then, our portfolio has grown, and we have made many updates to existing products. Having access to Ansys simulation has been and continues to be a big part of that.”

Ansys is dedicated to advancing industrial processes and equipment with innovative solutions. To learn how Ansys can support your early-to-mid-stage business, visit the Ansys Startup Program.

Just for you. We have some additional resources you may enjoy.

“Every new component we engineer undergoes an iterative simulation cycle: We evaluate its performance in the system, optimize the design, and then reevaluate it to validate the improvements.”

— Aleksandar Belberov, CTO, KEWAZO

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.