自動化讓那些擔心科技會取代人力的人們感到焦慮。但隨著我們從工業 4.0 轉型至工業 5.0,若能轉換焦點,某些顧慮可能會因此減輕。第四次工業革命以技術為中心,但第五次則強調人類與技術之間的互動與協作。歐盟委員會認為這次的革命比 4.0 更全面,且具備永續性、以人為本與韌性等支柱。這種焦點的轉變,正好迎來智慧製造的最佳時機。

什麼是智慧製造?根據 CESMII 智慧製造學會所述,智慧製造應包含工廠間及工廠內的實體與數位程序高效率協調。這家由政府資助的美國非營利組織強調,這樣的方法具有協作、資訊導向和事件導向的特性。它描述智慧製造流程為「整合、監控並持續評估,具備自動化常規任務所需的感測、資訊、分析模型和工作流程,並可針對非常規狀況採取行動。」智慧製造的成果自然帶動智慧工廠的發展,也稱為數位或智慧型工廠。

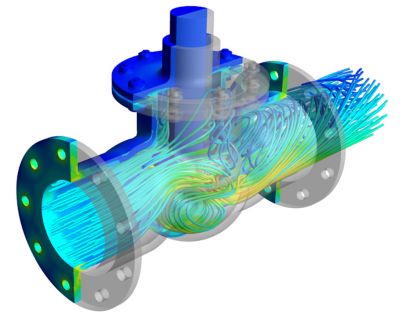

如果您想知道模擬功能如何融入其中,他們的交匯點就從這裡開始。首先,多物理模擬提供關鍵的深入見解和預測準確度,以支援上述感測資料和分析模型。接著它與人工智慧/機器學習 (AI/ML) 演算法整合,以最佳化此深入見解,並支援數位孿生、積層製造和自動化等先進技術。透過整合多物理模擬以採用智慧製程,工廠能有效且高效地化身為蓬勃發展的智慧工廠。

聰明有回報

根據 McKinsey & Co. 的資料,當解決方案成功結合先進的資料與分析、AI/ML 和其他技術,可將機器停機時間減少 30% 至 50%、吞吐量增加 10% 至 30%、勞動力生產力提高 15% 至 30%,並將預測準確度提高 85%。

智慧工廠的特徵是互聯的機器、網路與技術,例如 AI/ML、工業物聯網 (IIoT) 感測器,以及雲端運算能力,用來收集資訊、加速資料傳輸並精簡流程,且經常搭配自動化或機器人技術。

然而,並非每間智慧工廠都是相同的。一家工廠可能高度依賴 AI/ML,另一家工廠則仰賴雲端運算能力。同樣地,智慧工廠也需要由不同的網路驅動。例如,較小的工廠可能透過 Wi-Fi 驅動 IIoT 裝置。而較大型的工廠可能會使用行動網路,特別是私人 5G 網路,這些網路能提供更高的可靠度與高頻寬、低延遲,以及更高的安全性。

儘管每家智慧工廠都是獨一無二的,但所有智慧工廠都會從概念階段到產品的整個生命週期利用技術提升效率,包括營運與維護 (O&M)。製造產業的一個重要部分是新產品導入 (NPI)。與著重於概念或功能性的產品設計不同,NPI 著重於可製造性和可擴展性,並需要考慮效率、成本和上市時間等因素。因此,NPI 通常會邀請製造團隊參與早期的設計階段。這與智慧製造和工業 5.0 的核心十分吻合,著重於整體方法和效率考量,這同時也是智慧工廠背後的驅動力。

智慧工廠效率:

- 最佳化:透過 AI/ML 和雲端運算等技術,實現更快的資料傳輸、更高的擴充性和先進分析能力

- 工業自動化:能夠運用技術、機器和機器人來執行傳統由人類執行的任務和流程,例如棧板化與貨物接收等,以及包括脫粉在內的積層製造流程

- 工作流程自動化:能夠運用模擬最佳化軟體等數位解決方案來自動化數位工作流程

- 自動化:能夠使用數位孿生和 AI/ML 遠端控制、監控或監管自動裝置,以收集資料、確保效率並提高安全性

- 節省成本和永續性:透過虛擬測試和原型設計、預測性維護、更快的處理和高效的工程,包括更明智的材料選擇,從而降低支出並提高永續性

智慧型工廠利用技術和自動化來提高效率,例如在組裝線上導入機器人。

掌握領先地位

為了展示對效率和尖端技術的奉獻精神,有近 200 家製造商已加入「世界經濟論壇 (World Economic Forum)」的「全球燈塔網路 (Global Lighthouse Network)」。為了獲得「燈塔」的稱號,製造商必須大規模應用工業 4.0 技術,以「透過轉型工廠、價值鏈和商業模型,推動財務、營運和永續性的逐步改變。」

我們的一些工業領域客戶是「燈塔」製造商,包括 Tata Steel。

Tata Steel Nederland 知識小組研發負責人 Paul van Beurden 在一份新聞稿中表示:「創新推動進步,在 Tata Steel Nederland,我們正在開創邁向永續性的轉型旅程。「透過運用 Ansys TwinAI 軟體的強大功能,我們正在最佳化生產流程,將能源損耗降到最低,並推動到 2030 年將去碳化降低 30% 至 40% 的目標,到 2045 年實現碳中和目標。Ansys技術對我們實現目標至關重要。」

在現今不斷演進的數位環境中,產品開發團隊更進一步地支援資料融合,這種趨勢是「模擬左移」,也就是在設計和開發的初期便整合模擬功能。透過提早導入模擬功能,開發團隊能獲得關鍵見解,讓他們為設計提供資訊、預防產品故障、減少支出,並縮短上市時間。

同時,智慧工廠透過嵌入式感測器、AI/ML 和數位孿生,能在營運與維護期間將模擬的效益最大化,帶來即時系統分析和預測性維護等優勢,讓機器操作人員能更快偵測到問題。這能為資產健康表現與生命週期最佳化提供支援。它還能減少設備的停機時間和相關維修成本,同時透過鼓勵燃油效率和碳減少的深入見解,協助提高永續性。

同樣地,模擬也能推動積層製造 (也稱為 3D 列印) 等先進技術。這項技術透過提高首次列印嘗試的成功率支援永續性,協助使用者減少時間、能源消耗、材料浪費和試錯列印成本。積層製造也有助於確保供應鏈的安全,因為它能在當地大規模地按需生產零件。

Ansys 解決方案透過涵蓋從結構、流體到電子等工程領域的完整多物理模擬工具開放式生態系,為智慧製造提供支援。此外,Ansys Connect 解決方案能將整個組織的模擬、資料和資源連結到單一數位線程,讓數位工程變得更簡單,進而提升營運效率和協同合作能力。這些解決方案包括模擬流程與資料管理 (SPDM)、材料管理、流程整合與設計最佳化,以及基於模型的系統工程 (MBSE)。其他解決方案則支援特定技術與領域,例如數位孿生、AI/ML、積層製造,以及雲端運算。

以數位方式支援產業未來

在模擬功能的推動下,數位工程正在推動全球智慧工廠的發展,影響了從建築、運輸到汽車和航太等幾乎每個產業的製造業。根據 Mordor Intelligence 的資料,2025 年的智慧工廠市場估計為 3891.4 億美元,到 2030 年時,將成長到 6193.4 億美元。

瞭解 Ansys (現已與 Synopsys 合而為一) 如何透過創新的工業解決方案,致力於支援智慧製造和新一代智慧工廠。