-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

Let's hear from members of the Optics product team from Ansys, part of Synopsys, as they discuss how engineers in optics and photonics can overcome the most demanding simulation challenges. We'll explore how Ansys 2025 R2 is innovating around the three pillars that matter most to engineers: scalability, accuracy, and interoperability — and how the Ansys Lumerical platform, Ansys Zemax OpticStudio software, and Ansys Speos software are advancing the optical design landscape.

What are the main obstacles engineers face in optical and photonic simulation today?

Julien Muller, director of product management: Optical and photonic systems are growing in complexity, particularly in fields like consumer electronics, automotive, aerospace, and telecommunications. Engineers face enormous pressure to:

- Analyze complex light behaviors like stray light, ghosting, scattering, and diffraction, which are critical in applications like head-up displays (HUDs), cameras, and augmented and virtual reality (AR/VR) systems

- Simulate large-scale and high-resolution systems without compromising performance

- Evaluate any system from automotive lighting to lens-based applications through multiple points of view or design variations to deliver the most robust solution with the highest perceived quality while keeping development cycle time short

- Integrate optics with mechanical assemblies or virtual 3D environments seamlessly

Traditional tools often hit performance or interoperability walls. That’s where Ansys Optics delivers, providing a unified simulation ecosystem built for scale, accuracy, and integration.

How is the Lumerical platform pushing the boundaries of photonic simulation?

Charly Meyer, senior product manager: For photonics engineers, speed and scalability are constant hurdles, especially when working on large, data-heavy designs like metasurfaces or photonic integrated circuits (PICs). Simulations of this kind can quickly outpace even high-end local hardware, creating bottlenecks that limit innovation.

Ansys tackled this challenge head-on with multinode, multi-GPU acceleration in Lumerical 2025 R2, enabling simulations to be distributed across compute nodes and multiple GPUs. This lets engineers:

- Significantly accelerate simulation runtimes

- Scale designs without compromising accuracy

- Run large parametric sweeps and optimizations efficiently in on-premises high-performance computing (HPC) or cloud environments

- Extend GPU memory to handle ultra-high-resolution simulations

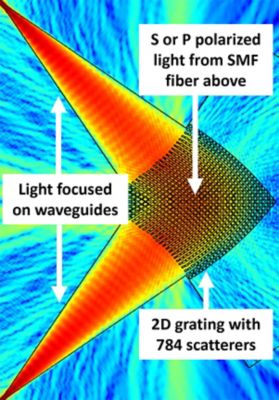

Inverse design optimization capacities were also improved in this latest release. Now users can specify the expected spatial localization of a given parameter for shape-based optimization problems. This feature enables parallelization of meshing when calculating how each parameter changes the permittivity and can significantly improve performance in problems with a large number of parameters, like for the optimization of polarization-splitting grating couplers (PSGC) used to couple light to PICs.

Lumerical software is critical for photonics innovation. Ansys is focused on enabling zero-prototype workflows by empowering engineers to fully validate device performance in silico. These capabilities support everything from R&D to large-scale deployment in integrated photonic systems.

Lisa Clauson, senior product manager: By enabling photonics engineers to simulate and iterate on extremely complex designs faster than ever before, Lumerical software removes traditional hardware limitations and lets innovation thrive. It's a foundational piece in building next-generation optical systems that integrate seamlessly with mechanical and system-level workflows.

Field intensity profile of a polarization-splitting grating coupler (PSGC) structure (top view)

But scalability isn’t just about raw compute. In 2025 R2, the Lumerical team also added support for the Ansys Cloud Burst Compute capability that enables engineers to instantly access high-performance cloud compute resources. It is a software-as-a-service (SaaS) capability with no installation or setup required. It uses pay-as-you-go credits, which include everything required to run a finite-difference time-domain (FDTD) job on the latest CPU or GPU hardware in cloud compute resources managed by Ansys. It makes it easier than ever to iterate quickly, even on the most computationally demanding photonic designs.

How is OpticStudio software pushing the boundaries of real-world accuracy with nonsequential optics?

Tom Pickering, manager of product management: Most optical systems aren’t idealized. Instead, they include real-world complexities. Light reflects off internal housing, scatters through baffles, and forms ghost images that degrade real-world performance. That’s why sequential ray tracing falls short.

OpticStudio software’s nonsequential component (NSC) mode, which is available in 2025 R2, lets engineers simulate these realities to capture how light behaves as it interacts with all the physical elements, including filters, coatings, mechanical structures, and enclosures.

Engineers can’t afford surprises when a prototype is built. NSC simulation gives them the confidence that what they’re designing is going to work in the real world, especially in safety-critical applications like automotive sensors or space optics. OpticStudio software also supports tolerancing, thermal effects, and mechanical integration, enabling tighter collaboration across engineering domains.

While Speos software focuses on full-system simulations, including mechanical scattering and 3D environment simulation, OpticStudio software is purpose-built for detailed component-level design, giving optical engineers precise control over performance at every stage.

How is the OpticStudio STAR capability enhancing interoperability with structural and thermal data?

As optical systems grow in complexity, understanding the impact of structural and thermal effects on optical performance becomes increasingly important. The OpticStudio Structural-Thermal-Optica Performance (STOP) solution addresses this need by enabling high-fidelity multiphysics simulations that connect mechanical and optical domains.

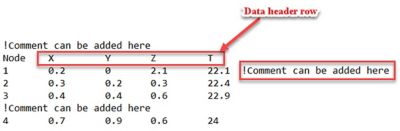

A key recent enhancement is the ability to include headers and comments in finite element analysis (FEA) datasets used within the OpticStudio Structural-Thermal-Optical Analysis and Results (STAR) Multiphysics Data Loader feature. This update enhances dataset readability and traceability, enabling engineers to clearly identify variable mappings, units, and assumptions within the file. By embedding documentation directly into the dataset, teams can more easily interpret simulation inputs, collaborate across disciplines, and maintain consistency in long-term or regulatory-driven projects. It also streamlines integration with the STAR Multiphysics Data Loader by reducing import errors and improving confidence in simulation results.

The ability to add headers and comments in FEA datasets streamlines integration with the Ansys Zemax OpticStudio STAR Multiphysics Data Loader.

Esteban Carbajal, senior product manager: Engineers working across optical, thermal, and mechanical domains need their data to be accurate, easy to interpret, and shareable. By making FEA datasets self-describing and better structured, we’re improving transparency and paving the way for more robust, collaborative multiphysics workflows. This update is a small but powerful step toward fully integrated optical system engineering.

How is Speos software connecting optical simulation to the virtual world?

Etienne Lesage, lead product manager: Engineers increasingly need to simulate optical systems within complex 3D environments or 3D scenes. It is hardly achievable considering only computer-aided design (CAD) assemblies. This is particularly true for camera sensor validation, AR/VR, and automotive lighting, in which predictive rendering in a 3D realistic environment is critical.

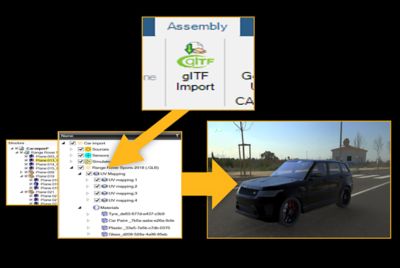

That’s why Speos 2025 R2 now supports glTF import, making it seamless to bring models in from 3D design modeling tools like Blender or Autodesk 3ds Max, or from platforms like NVIDIA Omniverse.

This preserves not just geometry but also textures and material properties, ensuring physically accurate simulations. Engineers can now assess image quality, glare, and illumination effects in fully detailed virtual scenes, whether it’s a city street at night or a headset in a living room.

An imported glTF file ready to be simulated with Ansys Speos software

Speos software is all about bringing real-world context to optical design through its integration with OpticStudio software, where the core optical design originates. Speos software then enhances this design by adding real-world simulation capabilities, enabling comprehensive evaluation of optical performance in realistic environments. By exchanging data with 3D design tools and platforms, we’re enabling visualization-driven design where engineers can iterate, test, and validate their systems faster and more creatively than ever before.

How can engineers achieve seamless interoperability across the Ansys Optics suite?

Muller: In Ansys 2025 R2, we are excited to introduce the Ansys Engineering Copilot tool for the Lumerical platform and Speos software. This is a major step forward in how engineers interact with simulation tools. As director of product at Ansys, I see the Engineering Copilot tool as a transformative leap. Our vision was to bridge the gap between deep technical expertise and intuitive usability. The Engineering Copilot feature does exactly that by leveraging generative pretrained transformer (GPT) technology to provide context-aware guidance. But it’s more than just convenience — it’s about making simulation more accessible across disciplines, accelerating innovation while maintaining the precision and fidelity Ansys is known for. This introduction of the Engineering Copilot tool is a first step toward a deeper integration of generative AI to help engineers gain productivity.

Software-as-a-service (SaaS) capability with no installation or setup required

Each Ansys Optics tool brings unique strengths to this effort:

- Lumerical software enables multiphysics simulation at the nanoscale with powerful HPC scalability.

- OpticStudio software offers industry-leading ray tracing and STOP analysis, bridging optical and mechanical design.

- Speos software delivers physically accurate, system-level optical simulations in a complex 3D virtual environment.

These tools interoperate seamlessly and support the entire optical design flow, from the device level to system integration and user experience. This unified platform breaks down silos, accelerates iteration, and empowers teams to deliver higher-quality products with fewer physical prototypes and faster time to market.

Ansys is committed to shaping the future of optics and photonics. Our mission is to help engineers design next-generation optical systems — faster, smarter, and with the confidence that their virtual prototypes will perform exactly as expected in the real world.

Ready to engineer the future of light? Explore the full suite of Ansys Optics solutions to see how you can level up your design workflows with tools built for innovation at every scale.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.