-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

ANSYS BLOG

March 15, 2023

Ansys Additive Simulation Joins Forces with Aconity3D to Print Defect-free Bike Bottom Lug Component

Additive manufacturing, or 3D printing, has been a buzzword for more than a decade now. As this technology continues to evolve and expand in value in industries like aerospace, defense, and healthcare, its unique advantages are becoming more apparent. These benefits include, but are not limited to, a high degree of design customization, lean manufacturing, and lightweighting. It's precisely these advantages that have led to an increasing number of industries embracing additive manufacturing to complement or even replace traditional manufacturing technologies. The high-end, custom sports equipment industry is a recent example of this trend, with the use of 3D printing in bicycle manufacturing.

Read on to see how 3D printing can be used to enhance the design, material usage efficiency, and manufacturing processes of a custom-built Dutch bicycle's bottom lug component. You’ll also learn how the Ansys Additive simulation product collection plays a vital role in helping engineers efficiently achieve first-time printing success like never before.

Fully 3D Printing a Bike in the Netherlands

Brightlands Chemelot Campus is one of the four campuses of an open innovation community located in the province of Limburg, Netherlands. At Brightlands, designers, researchers, and engineers have collaborated to create a fully 3D printed racing bike that meets the high-performance demands of being lightweight and highly customizable while still maintaining great durability and strength for unpredictable road conditions. To achieve this, they have used various high-performance materials and additive manufacturing technologies to create a lightweight, durable, and highly tailored bicycle frame.

The bottom lug, which connects different bike frame segments, is a critical component in the bike’s design. To manufacture this component, Brightlands worked with Aconity3D GmbH, an industry-leading machine manufacturer and additive manufacturing solution provider for laser-based 3D printing of metals, located in Aachen, Germany.

Figure 1. Brightlands 3D printed racing bike and bottom lug. Images courtesy of Brightlands Chemelot Campus.

3D Printing a Titanium Bottom Lug at Aconity3D

To ensure the custom-designed bike bottom lug is strong enough to endure harsh conditions while still being lightweight, Ti-6Al-4V was chosen as the printing material. This material is known for its superior specific strength and is widely used in aerospace and medical applications.

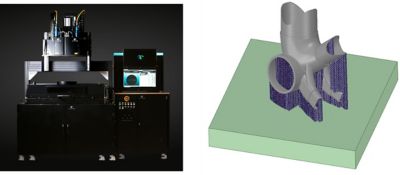

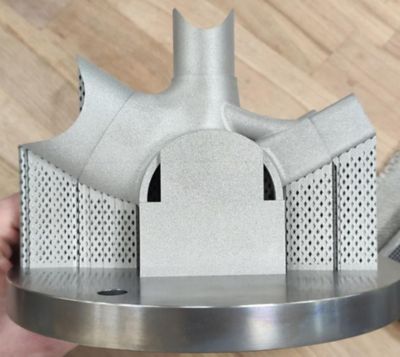

During the printing process, the bike bottom lug was oriented as shown in Figure 2, and a series of generated support structures were used where needed, based on printing experience. To perform the print job, an AconityMIDI+ laser powder bed fusion (LPBF) system was used at Aconity3D GmbH. While the bike component printed relatively well, there was an unexpected issue taking place.

Figure 2. Aconity MIDI+ LPBF system and initial build setup for bike bottom lug printing. Images courtesy of Aconity GmbH.

Addressing Delamination Challenges During the LPBF Process

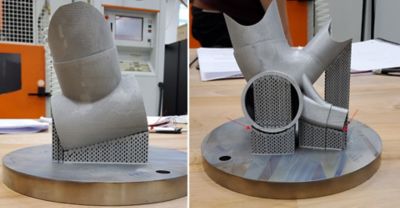

Support structures commonly used in LPBF builds are to constrain potential undesirable part deformations. In many cases, supports may be too weak to sustain a firm attachment to the as-built part geometry due to high strain inherited from the build process. As seen in Figure 3, due to high strain accumulation effects, critical delaminations occurred at the interfaces between the as-built bottom lug part and the support structures. Such a delamination typically occurs when strain at that location exceeds the elongation a material can withstand. As a result, the support structures were unable to effectively constrain the deformations of the as-built part, which could potentially lead to issues with geometrical tolerances.

Figure 3. Delamination defects observed in critical regions on the interface between bottom lug part and support structures. Images courtesy of Aconity GmbH.

Ansys Additive High Strain Detection Helps Identify Critical Regions During the LPBF Build

To solve this support structure delamination defect, Ansys and Aconity3D joined forces by integrating additive manufacturing process simulations into the manufacturing workflow. Ansys Additive LPBF simulations were used to quickly identify the critical areas and evaluate build orientation and support strategies. The LPBF simulation high strain result tool highlights critical strain regions, which enables engineers to identify regions of the part that may be prone to forming cracks during or after the build. Based on the simulation results, an optimized strategy was implemented for the physical validation print in a state-of-art Aconity MIDI+ LPBF system.

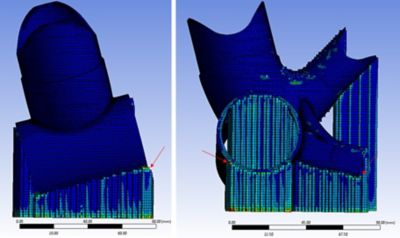

First, an inherent strain static structural model was used for simulating build setup with the exact build orientations and support structures from the defective build. The high strain feature was added to the simulation result section to detect the critical regions with high strain accumulation during the printing process.

Upon reviewing the simulation results, the identified high strain regions closely matched the locations where delaminations occurred during the actual build. These areas would likely serve as the initiation sites for delamination, which would then rapidly propagate through the adjacent interface between the bottom lug part and support structures.

By conducting a simulation evaluation of the first print build, the high strain detection feature from Ansys Additive simulation was shown to successfully deliver high-fidelity mapping to the critical areas that were observed and verified in the physical build.

Figure 4. Ansys Additive LPBF simulation captures the same critical regions where delaminations occurred in the physical build using high strain detection feature.

The next step involves enhancing the build orientation and support structures to prevent delamination defects. To achieve this, Aconity3D’s engineers took a leap of certainty by collaborating with Ansys Additive simulation before proceeding with the next physical build.

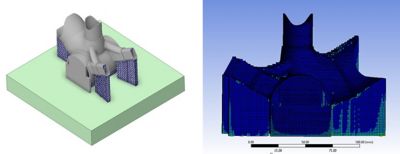

Based on the outcomes from the previous build, the AconityMIDI+ produced a great piece of component, even though the high strain occurred at the interface between part and supports, causing delaminations. To print it even better, Aconity3D's engineers revised the build orientations and strengthened the support structures in crucial areas. Instead of directly printing the next build, they teamed up with Ansys to perform a preliminary simulation with high strain detection enabled for the new build setup. The simulation results indicated a significant reduction in high strain regions along the interface between the newly oriented bottom lug part and the support structures, in comparison to the previous build setup.

By embedding process simulations into the Aconity3D’s manufacturing workflow, process engineers can easily evaluate and validate different orientation and support strategies in simulation first, before sending the build files to the machine floor. Therefore, the successful integration of simulation increases efficiency and reduces time and cost by reducing the number of test prints.

Figure 5. New bottom lug build setup with revised build orientations and enhanced support structures.

Achieving Defect-free Parts and First Time Print Right Goals

By combining Ansys Additive simulations into the workflow, Aconity3D's engineers were able to approach the printing of the reoriented bottom lug part with greater confidence. They successfully reinforced support structures at critical regions, resulting in a defect-free final product that met their expectations when it emerged from the AconityMIDI+ system chamber.

Figure 6. Bottom lug with no delamination defects manufactured using the new build orientation and support structures. Image courtesy of Aconity GmbH.

The success of the collaboration between Ansys and Aconity3D has realized the perfect printing of this bottom lug component. Once the component was assembled onto the racing bike at Brightlands Chemelot Campus, Menno Smeelen, the new business development manager, was thrilled to take it for a ride. The bike performed exceptionally well, delivering the high performance, durability, and strength required for challenging terrain.

To learn more about how Ansys Additive can help you with your 3D printing projects, click here.

Figure 7. Menno Smeelen from Brightlands rides the racing bike assembled with a 3D-printed bottom lug. Image courtesy of Brightlands Chemelot Campus.