From the application of artificial intelligence (AI) to wearables and personalized, patient-specific designs, medical device innovation has reached an inflection point. Today, the market for smart medical devices is $90.54 billion, and it’s expected to reach $185.5 billion by 2030, more than doubling in five years.

Optics plays a leading role — both in increasing device innovation and fueling overall market growth. From simple lenses to complex laser-based systems, the use of light and optics underlies a range of modern medical imaging devices, treatment techniques, and diagnostic tools. Consider these examples of optics at work in healthcare:

- Imaging systems. Devices like endoscopes rely on optical components to capture high-quality images of internal organs, tissues, and cells for diagnostic purposes.

- Laser treatments. Many modern medical therapies and beauty applications, such as laser eye surgery and laser hair removal, use optics to deliver precise laser beams to targeted areas.

- Surgical assistance. Advanced surgical systems incorporate optical-based navigation to provide surgeons with real-time visual information, enhancing their accuracy.

- Patient monitoring. Optical sensors are widely used in non-invasive monitoring devices like pulse oximeters and glucose measurement devices.

While optics has become increasingly critical in modern healthcare, the design of these systems comes with an array of engineering challenges. Medical devices must be compact and lightweight, which means that optical systems must be miniaturized without sacrificing performance. Optical components must also be incredibly precise in their design. Even the slightest misalignment or distortion in optical components can compromise the effectiveness of a device, leading to inaccurate results or even harmful outcomes.

Optical systems must also perform reliably in the face of temperature fluctuations and mechanical stresses. For example, lasers used in medical therapies generate heat, and optical components must withstand thermal effects without performance degradation.

These high-performance demands are accompanied by strict regulatory requirements. Optics-based medical devices must undergo rigorous validation and testing before they can be used on human patients. This, along with sustainability mandates, is placing new pressure on device manufacturers for energy efficiency, as well as high performance.

Finally, in today’s highly competitive healthcare markets, devices must be optimized for cost-effective production at speed and scale. Balancing performance with manufacturing cost constraints is essential to bring medical devices to market at competitive prices.

Simulation: An Early, Accurate Look at Device Performance

How can medical device development teams balance all these competing product demands while still working quickly to capture the innovation opportunity?

The answer is engineering simulation. By designing, testing, perfecting, and validating advanced optical designs in a risk-free virtual space, engineering teams can confidently produce leading-edge devices that simultaneously meet the tight constraints of size, weight, precision, durability, power usage, regulatory compliance, and manufacturing cost. They can drive significant time from the development cycle to speed innovative new designs to market — supporting both revenue growth and improved patient outcomes.

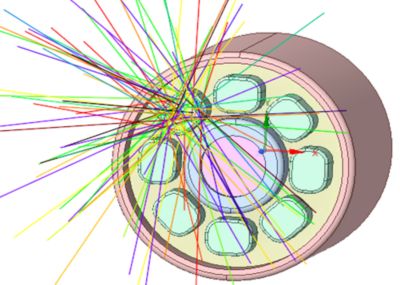

Optical ray-tracing to analyze the image quality of an endoscope camera system under different lighting conditions

Ansys Optics is a comprehensive simulation suite widely adopted by leading medical device manufacturers to accelerate the development of advanced optical architectures while meeting stringent requirements for performance, reliability, manufacturability, regulatory compliance, and sustainability.

Ansys Optics enables multiscale simulations ranging from full-wave electromagnetic models on the nanoscale to ray-tracing on the component and system level for complex optical assembly design in a virtual environment, allowing engineers to optimize key performance metrics across multiple domains simultaneously.

For healthcare applications, this can mean minimizing chromatic and monochromatic aberrations in imaging systems, maximizing optical throughput and signal-to-noise ratios, or achieving precise focal plane and depth-of-field requirements. By performing these analyses upfront, engineers reduce reliance on costly physical prototyping cycles and accelerate convergence to manufacturable designs.

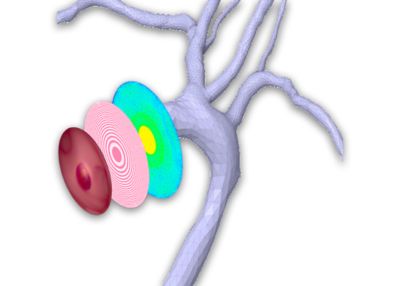

Medical optics must function as part of multiphysics systems, where optical behavior is strongly coupled to mechanical, electrical, and thermal effects. Ansys Optics enables engineers to evaluate device performance under real-world operating conditions. For example, in the development of a laser-based therapeutic platform, engineers can simultaneously model Gaussian beam propagation, scattering in biological tissue, and thermo-mechanical deformation of optical components. These coupled simulations ensure that lenses, mirrors, and fibers remain within tolerance, minimizing beam steering errors and preserving energy delivery precision.

In addition, optics solutions from Ansys, part of Synopsys, support thermal-optical and stress-optical modeling, enabling engineers to predict refractive index changes, birefringence, and lens warping due to temperature gradients. With these insights, teams can implement thermal mitigation strategies, such as optimized heat sinking, athermal lens designs, or active cooling solutions, to ensure consistent device performance under elevated operating loads.

By combining rigorous electromagnetic solvers with system-level multiphysics analysis, Ansys Optics provides optical and photonics engineers with a robust framework for designing next-generation medical devices that meet optical performance targets and stringent regulatory and reliability standards.

Metalens-based fiber-optic endoscope design to reduce the size of the device, which poses main limitations on clinical applications

Faster, More Cost-Effective, More Compliant Designs

By enabling rapid, high-fidelity design iterations, Ansys Optics significantly accelerates the optical product development cycle and facilitates innovation in medical optics and photonics.

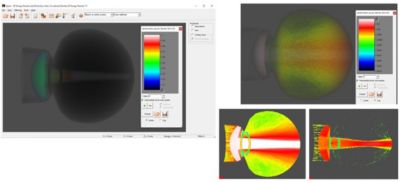

Engineers can leverage a combination of ray-tracing, wave-optics, and structural and thermal solvers for multiphysics simulations to virtually explore a broad design space, evaluating multiple optical architectures, coatings, source models, and material selections without fabricating hardware. This virtual prototyping approach reduces reliance on costly iterations, enables earlier identification of aberrations, stray light, or thermal-induced misalignments, and ultimately shortens time to market while improving manufacturability.

Ansys simulation also streamlines the path to regulatory compliance, a critical requirement in the medical device sector, where optical safety and performance standards are tightly enforced. Using optics solutions from Ansys, engineers can simulate and validate device behavior. By generating simulation-based evidence, Ansys Optics not only supports design verification and validation but provides the documentation required for regulatory submissions, reducing delays associated with physical test-only strategies.

Furthermore, engineers can conduct advanced risk and failure mode analyses, such as modeling thermal runaway in high-power laser diodes or simulating worst-case stray-light conditions in diagnostic imaging systems, ensuring that safety margins are satisfied prior to prototyping and clinical testing.

Through its ability to couple optical, thermal, structural, and electromagnetic analyses within a single platform, Ansys Optics empowers photonics engineers to design devices that achieve both technical excellence and regulatory compliance efficiently and with high confidence.

Simulation of cataract vision, which shows increased light scatter and reduced focus compared with normal vision

Case Studies: A Glimpse of Ansys Optics in Action

Hundreds of customers, including healthcare leaders, have leveraged the power of Ansys Optics to optimize their optical systems and improve the performance of their products. Let’s look at three examples in the healthcare industry.

Cornell University

A visionary team of researchers at Cornell University used Ansys Optics to develop a new instrument for multiphoton microscopy (MPM) at the micron scale. While existing commercial spectrophotometers only accommodated deep imaging within highly scattered living tissue at the centimeter scale, Chris Xu and Aaron Mok wanted to measure optical transmission in much smaller specimens, including mouse skulls, mosquito and fruit fly cuticles, and the skin of Danionella, one of the world’s smallest fish. They used Ansys Zemax OpticStudio optical system design and analysis software to test and verify their new instrument, proving the effectiveness of using single-mode optical fibers to isolate ballistic photons in the tissue spectrometer, generate spatially resolved transmission maps for five types of micron-scale tissue samples, and provide a measurement system for tissue analysis at a very small scale.

INAOE

During the pandemic, Jorge de Jesus Alvarado-Martinez and his team at the Instituto Nacional de Astrofísica, Óptica, y Electrónica (INAOE) developed an optical system to improve thermal imaging technology for syndromic surveillance. The system identifies people with elevated temperatures, a key indicator of serious infections, and differentiates crowd members based on bioclinical signals like cough and temperature. Off-axis mirrors were chosen for this solution, as they eliminate obscuration and provide a wide field of view (FOV). The team used the Footprint Diagram tool in OpticStudio software to observe parameter values based on aperture size and FOV dependency. The system achieved cost savings, faster development, and easier materials selection. This innovative approach aims to improve public health by detecting, monitoring, and understanding health events, enabling timely response and intervention to protect populations from exposure.

Imperial College London

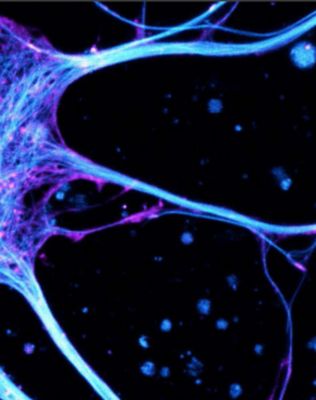

Researchers at Imperial College London used optical design software from Ansys to pioneer a new method of lens selection for fluorescent microscopes that must be refocused remotely. While 3D imaging in optical systems often involves scanning the sample or moving the objective back and forth with respect to the sample, these methods often fall short — because movement produces vibrations. Christopher Dunsby and Wenzhi Hong used OpticStudio software — which includes a dynamic catalog of stock manufactured lenses — to define a standardized, reliable practice for lens selection. Their formula states that the overall magnification must equal the ratio of the sample medium's refractive index to the refractive index in which the image is formed. By automating this process, Dunsby and Hong are eliminating guesswork and accelerating microscopy design for optics teams worldwide.

A fluorescence microscopy image showing interconnected neural networks with highlighted axonal pathways and synaptic structures

Increase Your Focus on Innovation With Ansys

The integration of simulation into the design process is no longer a luxury but a necessity for staying competitive and fueling innovation in the fast-paced healthcare market. By leveraging the power of Ansys Optics, product development teams can create optics-based medical devices that push the boundaries of what’s possible, ultimately improving patient outcomes and advancing healthcare technologies.

Learn more about Ansys Optics, optics miniaturization, simulation-driven medical device development, and other topics at ansys.com. Or contact the Ansys Optics team to discuss your own unique design challenges and opportunities.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.