-

-

학생용 무료 소프트웨어에 액세스하기

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

-

지금 바로 Ansys에 연결하십시오!

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

국가

무료 트라이얼

제품 및 서비스

학습하기

회사 정보

Back

제품 및 서비스

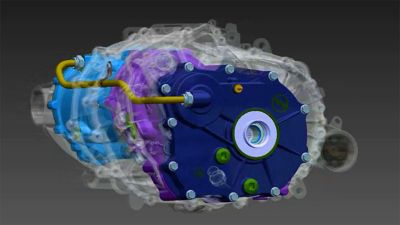

AAM relies on Ansys, part of Synopsys, to support electric driveline technology optimization for more efficient powertrain performance at a lower cost.

Electric vehicles (EVs) are gaining traction in global automotive markets, with 22 million electric cars sold this year — an increase of 25% over 2024. But consumers are adopting EVs on a largely regional basis. About two-thirds of EV sales are made in China, with Europe accounting for 17% of sales. Currently, U.S. consumers buy only 7% of all EVs, and that number may decline as the U.S. government rolls back EV mandates and incentives.

Why are consumers in the U.S. and other markets reluctant to embrace vehicle electrification? A recent AAA survey of American consumers found that top concerns include high purchase price (named by 59% of respondents), limited charging range (55%), and a lack of convenient charging stations (56%). According to BloombergNEF’s 2025 Electric Vehicles Outlook, overcoming affordability challenges for both vehicles and charging is critical to support higher EV adoption.

Based in Detroit, AAM is at the forefront of electric propulsion innovations aimed at delivering value for its customers, who include the world’s top automakers. As a leading global Tier 1 automotive supplier, AAM is focused on addressing consumers’ concerns and offering automakers powertrain designs that are optimized for cost, range, energy storage, and other parameters. That means making fast, smart design trade-offs among multiple components and systems in the finished powertrain.

AAM relies on the Ansys ConceptEV design platform for EV powertrains to bring multiphysics, multicomponent engineers together in a low-cost, low-risk virtual design space built for dynamic collaboration. AAM engineers connect their motor, inverter, transmission, and battery designs in a single system-level simulation to evaluate overall powertrain behavior and vehicle performance. This enables them to optimize across many components simultaneously, quickly, and cost-effectively.

According to Tony Pistagnesi, executive director of innovation and business development at AAM, this purpose-built Ansys solution has proven essential in driving innovations that address buyer concerns — and helping convince consumers in the U.S. and other regions to go green.

“It’s not enough to just build the best technology — we have to meet the market where it is,” Pistagnesi says. “Ansys ConceptEV software helps us do that by enabling informed trade-offs across mechanical, electromagnetic, and power electronics domains, ensuring we optimize not just for performance but also for cost and efficiency.”

Pistagnesi notes that, by creating a single workflow, a standard dataset, and shared system-level requirements, ConceptEV software empowers engineers to work both faster and more collaboratively. Functional siloes; manual handoffs; and single-physics, component-level simulations are eliminated.

“ConceptEV software gives us a powerful environment to evaluate and iterate quickly on electric propulsion architectures, helping us respond to the fast-moving demands of the industry,” Pistagnesi says. “The flexibility and speed of the tool are key enablers in a market where expectations, technologies, and cost inputs are constantly shifting.”

Based in Detroit, AAM is at the forefront of electric powertrain innovations aimed at charging up electric vehicle (EV) sales for its customers, which include the world’s top automakers.

Powering Faster, More Cost-Effective EV Innovation

As director of product engineering for electrification at AAM, Sean Stanley has seen the dramatic impact of ConceptEV software firsthand. “Historically, the automotive world has worked in a serial fashion — where first, we have vehicle-level specification, then system-level specification, then component-level specifications. And it can take months to get to the component level,” Stanley says.

“With ConceptEV software, we’re designing the powertrain system and its components — like the battery pack, the gearbox, and the inverter — concurrently in one shared design space,” Stanley says. “We make and evaluate component-level design decisions iteratively and see how those bubble up to vehicle performance parameters. And it’s not just one component engineer. It’s all the component engineers, working in the same macro environment alongside the vehicle-level engineers.”

Driving out vehicle costs while improving EV performance and range is a complicated proposition, according to Stanley. “In designing each component, you make certain assumptions about how it fits into the overall architecture of the vehicle,” he says. “You may not even realize it, but something as simple as changing system voltage or phase current can really limit the amount of optimization you can do for other parts. You could be limiting the system performance and the customer value without even realizing it.

“ConceptEV software illuminates those design trade-offs and their unintended consequences,” Stanley says. “For example, if you pull cells out of the battery pack to reduce its costs and weight, it could impact the battery voltage. As voltage goes down, the motor can't produce as much power anymore, so the inverter has to run more current. So, is that battery adjustment the proper decision to provide customer value? Can we drive out cost and weight elsewhere? Maybe by using a different power switch material for the inverter? Or by changing the lamination thickness or material of the motor?

“Before ConceptEV software, those were really hard questions that might take months to answer,” Stanley says. “Now we get answers in real time, as engineers make and assess those changes in a shared virtual space.”

An AAM engineer using Ansys ConceptEV software to drive automotive innovation in electric driveline technology

Enabling Customer Collaboration and Value Creation

Not only can the AAM engineering team get fast insights that inform their current designs, but they can also more effectively talk to customers about future designs and game-changing propulsion system innovations. According to Pistagnesi, AAM’s use of ConceptEV software is changing the company’s practices for customer collaboration and driving new industry norms.

“As an industry, we have to get past the idea that the customer defines the specification and the Tier 1 suppliers respond to it,” says Pistagnesi. “Having conversations with our customers about the range of design options — and what those options mean in terms of performance attributes, efficiency, and cost — is critically important.

“Today we can have those customer conversations easily with the ConceptEV platform and its visualization tools. It’s very fast and easy to show them some options,” he notes. “For me, that's been the most exciting part. On the back end, we’re saving so much time by running fewer simulations. That means, on the front end, our engineers can spend more time with customers and have richer conversations about their specific needs. ConceptEV creates a lot of room for value creation.”

AAM recognized Ansys, part of Synopsys, with an AAM 2025 Supplier Excellence Award, specifically for innovation performance. Pictured from left to right: Fred Solomon, vice president of global procurement and SQE at AAM; Derrick Hesser, enterprise sales director of transportation at Synopsys; Judy Curran, senior chief technologist at Ansys; and Mike Lynch, president and chief operating officer at AAM.

AAM and Ansys: Driving Innovation

Both Pistagnesi and Stanley emphasize that ConceptEV software is playing a central role as AAM pursues both EV innovation and global market growth.

“We can really push the envelope and spark design innovation while proving to our customers those innovations will work in real-world applications,” Stanley says. “ConceptEV software has put us in a position where it’s hard to argue that we’re providing value. It’s obvious what the right design decisions are. And we’re making them, quickly and confidently.

“Ansys and AAM share a commitment to innovation. And that’s really what makes our partnership with Ansys so successful,” Stanley adds.

“Ansys has been more than just a software provider,” says Pistagnesi. “They really listen to the types of problems we're trying to solve. And they’ve developed the ConceptEV software in a way that allows us solve those problems. ConceptEV software gives us a very powerful environment where we can iterate quickly, simulate multiple possibilities, and optimize all powertrain subsystems at the same time. That’s not available in any other software today.”

Interested in learning more about ConceptEV software? Watch this product demo. And make sure to visit our ConceptEV product page and sign up for a free trial.

Just for you. We have some additional resources you may enjoy.

“It’s not enough to just build the best technology — we have to meet the market where it is. Ansys ConceptEV software helps us do that ...”

— Tony Pistagnesi, executive director of innovation and business development, AAM

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.