-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

ANSYS BLOG

January 30, 2020

What is Pump Cavitation and How to Prevent It

Pumps, impellers and propellers are a fundamental part of everyday infrastructure. They keep power plants, boats and production facilities running all around the world.

A major concern for the engineers who design and utilize these machines is to avoid cavitation — where the fluid undergoes sudden phase changes that can physically damage mechanisms.

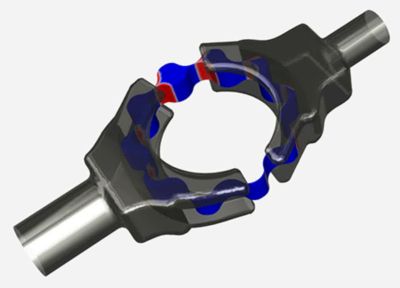

Pump cavitation can harm internal mechanisms.

To prevent this, engineers need to ensure that the right equipment is installed into the right system. Simulations are a cost-effective solution to optimize pump designs and configurations to avoid inadvertent phase changes.

What is Pump Cavitation and What Causes It?

Cavitation happens when bubbles, or voids, form within a fluid because the pressure quickly drops below the vapor pressure. When the bubbles experience higher pressures they collapse, creating small shockwaves that, over time, damage parts. When these pressure waves punch tiny holes into parts, it’s called pitting.

Propellers pitted from cavitation

Noise, vibration and reduced performance are good indicators of pump cavitation. When these warning signs start, engineers should inspect the equipment to see if any pits have formed.

Pitting is one of the primary concerns for engineers. This is because as the pits grow and multiply, they can reduce the pump’s life and efficiency.

Impacts of Cavitation on a Pump

But there are other reasons engineers will want to reduce the formation of bubbles in their equipment. For instance, the pressure waves can produce vibrations which could cause other parts to fail — like a bearing.

Since pump cavitation also affects a design’s flow rate and efficiency, engineers will have to increase power consumption to maintain throughput. This leads to increased greenhouse gases and fuel costs.

How to Prevent Pump Cavitation

The best way to prevent pumps from experiencing cavitation is to increase the pressure upstream from the pump’s impeller. This pressure is known as the net positive suction head (NPSH).

An Ansys EnSight visualization of oil volume in a gerotor pump shows the

extent of cavitation (red) on the gear wall.

Some ways engineers can increase NPSH:

- Increase the upstream reservoir’s water level

- Add an inducer to the pump inlet

- Optimize impeller design

- Minimize upstream flow losses

- Operate the pump at lower flow rates

In the design phase, engineers are unlikely to know how a pump will be set up within a given installation. Therefore, they use calculations and simulations to test out various configurations to provide the end users with appropriate NPSH ratings. These ratings help pair a pump to an installation.

Traditionally, engineers used the Rayleigh-Plesset equation to simulate bubble formation. The challenge is that these results are empirical and can return unrealistic outcomes if input parameters were improperly tuned.

Alternatively, engineers can use an equilibrium phase change model in Ansys CFX to simulate cavitation. It uses materials properties to predict the formation of bubbles without empirical data. As a result, it doesn’t require the tuning of the Rayleigh-Plesset equation to produce accurate results.

Engineers can then parameterize the simulation so they can quickly cycle their designs through various configurations to produce NPSH ratings. They can also create a chart that shows how reductions in NPSH will reduce the head generated by the pump due to sudden phase changes.

To learn about the equilibrium phase change model, check out this application brief: Cavitation: A Critical CFD App You Have to Get Right.

Any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans such as Ansys, Ansys CFX and EnSight are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries.