Ansys Motor-CAD and Ansys Maxwell: The Ideal Product Combo

Discover how the use of both Ansys Motor-CAD and Ansys Maxwell simulation tools can add significant benefits to your motor design and allow you to push the boundaries to drive innovation.

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

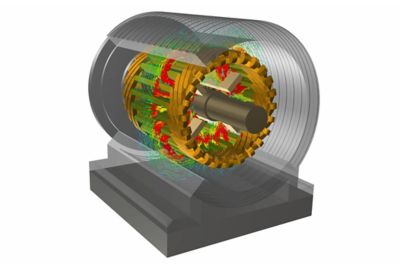

Full system integration from the concept design stages to analysis optimization and verification

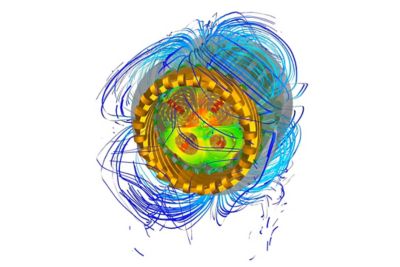

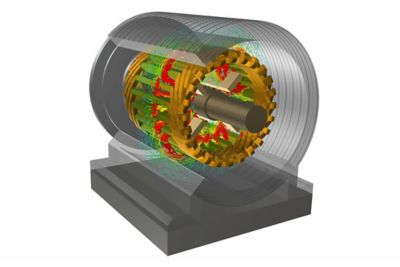

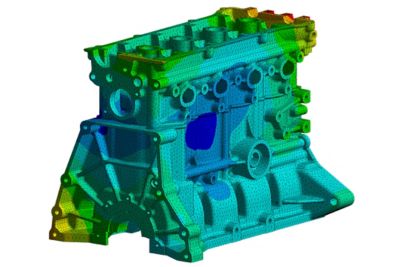

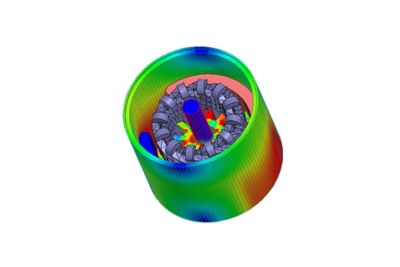

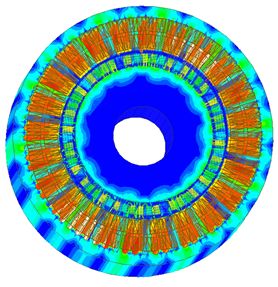

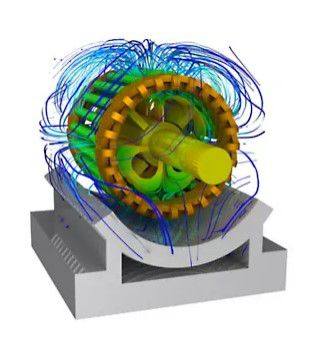

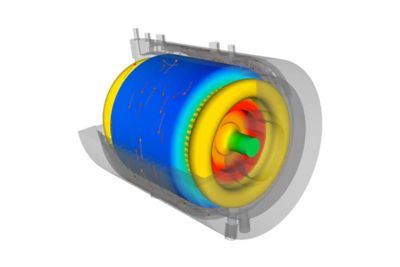

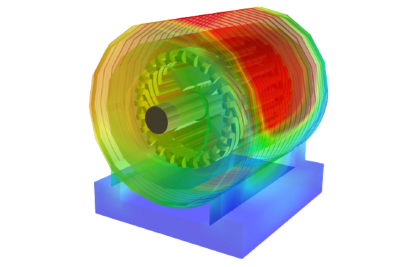

Ansys offers a complete workflow that progresses from concept design to detailed electromagnetics, thermal and mechanical analyses of the motor. Coupled electromagnetic-thermal-stress-and vibro-acoustics simulation of the motor using Ansys tools results in a high-fidelity, accurate and robust design that is optimized for performance, cost and efficiency.

Watch an overview of the complete ANSYS motor design flow.

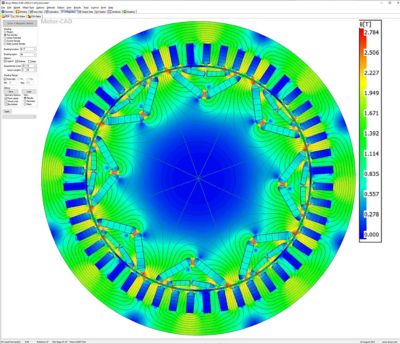

Discover how the use of both Ansys Motor-CAD and Ansys Maxwell simulation tools can add significant benefits to your motor design and allow you to push the boundaries to drive innovation.

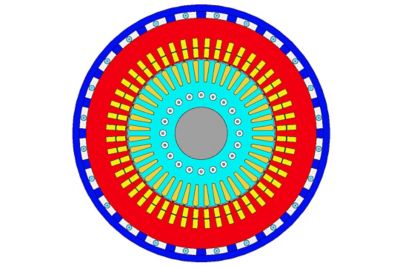

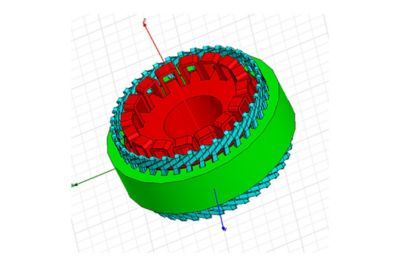

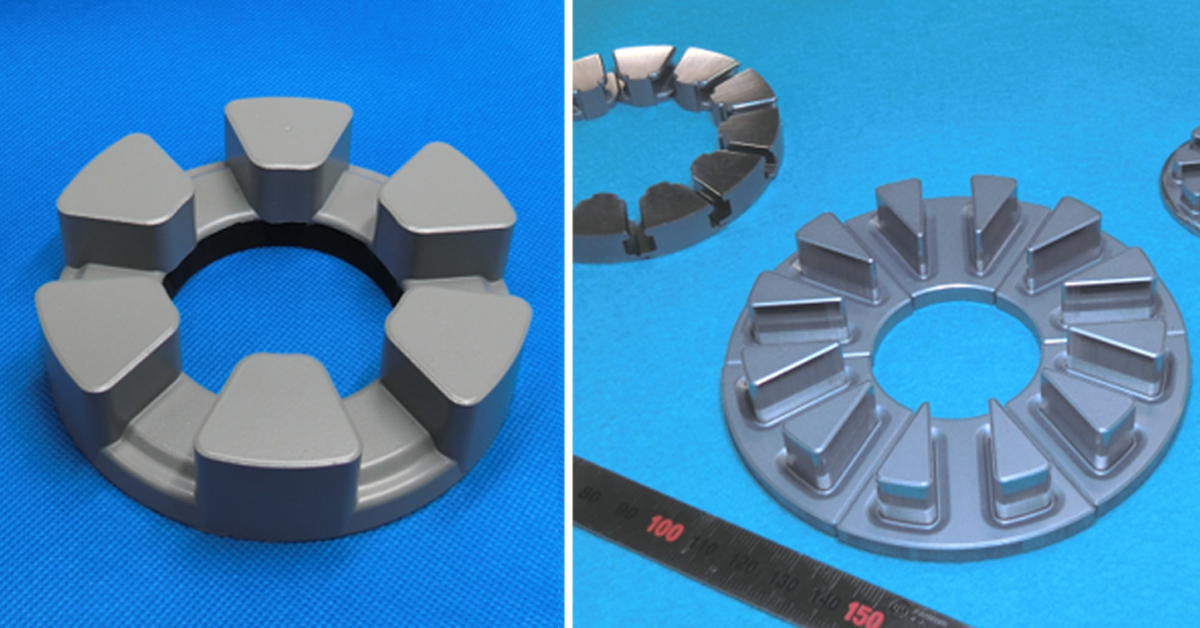

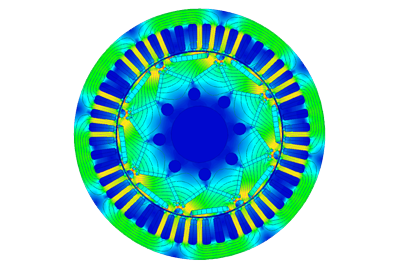

Comprehensive and powerful geometry templates cover a huge range of electric machine technologies, topologies and cooling systems. Ratio-based parameterization options provide unprecedented capabilities for parametric design optimization.

Quickly analyze the performance of designs over the operating envelope, including field weakening behavior.

Coupled multi-physics analysis from the start of the design process and built-in control algorithms enable virtual testing considering temperature effects over transient drive cycles or at steady state.

Ability to predict the thermal behavior of electric machines through a built-in 3D thermal network.

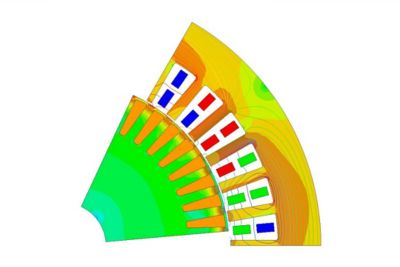

The electromagnetic design and optimization of the motor, provided by Ansys Maxwell and Ansys optiSLang, determines the radial, tangential, and axial forces associated with the machine's performance.

The acoustic representations of radiating vibrational noise are imported into Ansys Sound, enabling users to hear the electric motor at varying rpms.

Simulation results from Ansys Maxwell and Ansys Mechanical provide key inputs to realize the goal of measuring auditory perception and assessing a vehicle’s NVH performance. The structural simulation incorporates these forces in the presence of the motor housing.

Hearing the motor enables engineers to isolate and identify sub-components of the acoustic profile and investigate the influence on human perception.

Electric Machine Webinar Series

Simulating the noise, vibration and harshness (NVH) of an electric motor is important for proper electromagnetic (EM) and vibro-acoustic design of electric vehicles (EVs)

Learn how Ansys Customers have been able to address product development challenges by adopting Ansys solutions for electric machine design

Ansys offers a full system integration based on the ability to extract information from the design stages into analysis, design for validation and into the final verification stage. This enables full system simulation in one workflow.

ANSYS Maxwell is a comprehensive electromagnetic field simulation software for engineers tasked with designing and analyzing 3D/2D structures, such as motors, actuators, transformers and other electric and electromechanical devices. Based on the Finite Element Method (FEM), Maxwell can solve static, frequency-domain and time-varying electromagnetic and electric fields.

ANSYS Maxwell is a comprehensive electromagnetic field simulation software for engineers tasked with designing and analyzing 3D/2D structures, such as motors, actuators, transformers and other electric and electromechanical devices. Based on the Finite Element Method (FEM), Maxwell can solve static, frequency-domain and time-varying electromagnetic and electric fields.

Learn how ANSYS Maxwell can be used as part of a multiphysics simulation protocol to reduce noise, vibration and harshness (NVH) caused by wind, powertrain and road noise in moving vehicles.

Telma manufactures friction-free magnetic induction brakes for large trucks and other vehicles to ensure continuous braking over long periods of time. They use three Ansys simulation solutions — Ansys Maxwell for electromagnetics, Ansys Mechanical for structures and ANSYS CFD for air flow — in multiphysics simulations to design these wear-free, eco-friendly, long-lasting brakes. Telma engineers were able to increase braking performance by 30% while reducing the mass of the brakes by 25% using Ansys multiphysics simulation.

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.